Ethanol fermentation: Difference between revisions

m Reverted edits by Rockincon1 (talk) to last version by RJFJR |

→Alcoholic beverages: Clean up |

||

| (534 intermediate revisions by more than 100 users not shown) | |||

| Line 1: | Line 1: | ||

{{Short description|Biological process that produces ethanol and carbon dioxide as by-products}} |

|||

{{Main|Fermentation (biochemistry)}} |

|||

[[File:Ethanol fermentation-1.svg|thumb|upright=1.5|(1) A glucose molecule is broken down via glycolysis, yielding two pyruvate molecules. The energy released by this exothermic reactions is used to phosphorylate two ADP molecules, yielding two ATP molecules, and to reduce two molecules of NAD+ to NADH. (2) The two pyruvate molecules are broken down, yielding two acetaldehyde molecule and giving off two molecules of carbon dioxide. (3) The two molecules of NADH reduce the two acetaldehyde molecules to two molecules of ethanol; this converts NADH back into NAD+.]] |

|||

'''Ethanol fermentation''' is the biological process by which sugars such as [[glucose]], [[fructose]], and [[sucrose]] are converted into cellular energy and thereby producing [[ethanol]] and [[carbon dioxide]] as metabolic waste products. [[Yeast]]s carry out ethanol fermentation on sugars in the absence of oxygen. Because the process does not require oxygen, ethanol fermentation is classified as [[anaerobic]]. Ethanol fermentation is responsible for the rising of bread dough, the production of ethanol in [[alcoholic beverage]]s, and for much of the production of ethanol for use as fuel. |

|||

'''Ethanol fermentation''', also called '''alcoholic fermentation''', is a [[biological process]] which converts [[sugar]]s such as [[glucose]], [[fructose]], and [[sucrose]] into [[adenosine triphosphate|cellular energy]], producing [[ethanol]] and [[carbon dioxide]] as by-products. Because [[yeast]]s perform this conversion in the absence of [[oxygen]], alcoholic [[fermentation]] is considered an [[Anaerobic organism#Metabolism|anaerobic]] process. It also takes place in some species of fish (including [[goldfish]] and [[carp]]) where (along with lactic acid fermentation) it provides energy when oxygen is scarce.<ref>{{cite book|author1=Aren van Waarde|author-link=Aren van Waarde|author2=G. Van den Thillart|author3=Maria Verhagen|author3-link=Maria Verhagen|title=Surviving Hypoxia|date=1993|isbn=978-0849342264|pages=157−70|chapter=Ethanol Formation and pH-Regulation in Fish|hdl=11370/3196a88e-a978-4293-8f6f-cd6876d8c428}}</ref> |

|||

Ethanol fermentation is the basis for [[alcoholic beverage]]s, [[ethanol fuel]] and [[bread]] dough rising. |

|||

==The chemical process of fermentation== |

|||

The [[chemical equation]] below summarizes ethanol fermentation, in which one [[hexose]] molecule is converted into two [[ethanol]] molecules and two [[carbon dioxide]] molecules: |

|||

==Biochemical process of fermentation of sucrose== |

|||

::C<sub>6</sub>H<sub>12</sub>O<sub>6</sub> → 2 C<sub>2</sub>H<sub>5</sub>OH + 2 CO<sub>2</sub> |

|||

[[File:Gæring.png|thumb|upright|A laboratory vessel being used for the fermentation of [[straw]]]] |

|||

[[File:Yeast fermentation.jpg|thumb|upright|Fermentation of sucrose by yeast]] |

|||

The [[chemical equation]]s below summarize the fermentation of sucrose (C<sub>12</sub>H<sub>22</sub>O<sub>11</sub>) into ethanol (C<sub>2</sub>H<sub>5</sub>OH). Alcoholic fermentation converts one [[Mole (unit)|mole]] of [[glucose]] into two moles of ethanol and two moles of carbon dioxide, producing two moles of [[Adenosine triphosphate|ATP]] in the process. |

|||

The process begins with a molecule of [[glucose]] being broken down by the process of [[glycolysis]] into [[pyruvate]]:<ref name="stryer">{{cite book|title=Biochemistry|author=Stryer, Lubert|year=1975|publisher=W. H. Freeman and Company|isbn=0-7167-0174-X}}</ref> |

|||

:C<sub>6</sub>H<sub>12</sub>O<sub>6</sub> + 2 ADP + 2 P<sub>i</sub> → 2 C<sub>2</sub>H<sub>5</sub>OH + 2 CO<sub>2</sub> + 2 ATP |

|||

[[Sucrose]] is a sugar composed of a glucose linked to a fructose. In the first step of alcoholic fermentation, the enzyme [[invertase]] cleaves the [[glycosidic bond|glycosidic linkage]] between the glucose and fructose molecules. |

|||

This reaction is accompanied by the reduction of two molecules of [[Nicotinamide adenine dinucleotide|NAD<sup>+</sup>]] to [[Nicotinamide adenine dinucleotide|NADH]] and a net of two [[Adenosine diphosphate|ADP]] molecules converted to two [[Adenosine triphosphate|ATP]] plus the two water molecules. |

|||

: <chem> C12H22O11{} + H2O ->[\text{Invertase}] 2 C6H12O6 </chem> |

|||

Pyruvate is then converted to [[acetaldehyde]] and carbon dioxide. The acetaldehyde is subsequently reduced to ethanol by the NADH from the previous glycolysis, which is returned to NAD<sup>+</sup>:<ref name="stryer"/> |

|||

Next, each glucose molecule is broken down into two [[pyruvate]] molecules in a process known as [[glycolysis]].<ref name="stryer">{{cite book|title=Biochemistry|author=Stryer, Lubert|year=1975|publisher=W. H. Freeman and Co.|isbn=978-0716701743|url-access=registration|url=https://archive.org/details/biochemistry00stry_1}}{{page?|date=October 2021}}</ref> Glycolysis is summarized by the equation: |

|||

::CH<sub>3</sub>COCOO<sup>−</sup> + H<sup>+</sup> → CH<sub>3</sub>CHO + CO<sub>2</sub> |

|||

: |

:C<sub>6</sub>H<sub>12</sub>O<sub>6</sub> + 2 ADP + 2 P<sub>i</sub> + 2 NAD<sup>+</sup> → 2 CH<sub>3</sub>COCOO<sup>−</sup> + 2 ATP + 2 NADH + 2 H<sub>2</sub>O + 2 H<sup>+</sup> |

||

CH<sub>3</sub>COCOO<sup>−</sup> is pyruvate, and P<sub>i</sub> is inorganic [[phosphate]]. Finally, pyruvate is converted to ethanol and CO<sub>2</sub> in two steps, regenerating oxidized NAD+ needed for glycolysis: |

|||

Many species of Yeast (K. lactis, K lipolytica) will oxidize pyruvate completely to carbon dioxide and water (respiration) if oxygen is present in the environment and will ferment only in an anaerobic environment. However, the commonly used bakers Yeast S. cerevisiae |

|||

:1. CH<sub>3</sub>COCOO<sup>−</sup> + H<sup>+</sup> → CH<sub>3</sub>CHO + CO<sub>2</sub> |

|||

as well the yeast S. pombe, both prefer fermentation to respiration even in the presence of oxygen and will yield ethanol even under aerobic conditions given the right sources of nutrition. |

|||

catalyzed by [[pyruvate decarboxylase]] |

|||

:2. CH<sub>3</sub>CHO + NADH + H<sup>+</sup> → C<sub>2</sub>H<sub>5</sub>OH + NAD<sup>+</sup> |

|||

This reaction is catalyzed by [[alcohol dehydrogenase]] (ADH1 in baker's yeast).<ref>{{cite journal|pmid=25157460| doi=10.1021/bi5006442|vauthors=Raj SB, Ramaswamy S, Plapp BV |title=Yeast alcohol dehydrogenase structure and catalysis|journal=Biochemistry| year=2014|volume=53| issue=36| pages=5791–6503|pmc=4165444}}</ref> |

|||

As shown by the reaction equation, glycolysis causes the reduction of two molecules of [[Nicotinamide adenine dinucleotide|NAD<sup>+</sup>]] to [[Nicotinamide adenine dinucleotide|NADH]]. Two [[Adenosine diphosphate|ADP]] molecules are also converted to two ATP and two water molecules via [[substrate-level phosphorylation]]. |

|||

===Related processes=== |

|||

{{Main|Fermentation (biochemistry)}} |

|||

Fermentation of sugar to ethanol and {{CO2}} can also be done by ''[[Zymomonas mobilis]]'', however the path is slightly different since formation of pyruvate does not happen by glycolysis but instead by the [[Entner–Doudoroff pathway]]. |

|||

Other [[microorganism]]s can produce ethanol from sugars by fermentation but often only as a side product. Examples are<ref>{{Cite book|title=eLS|last=Müller|first=Volker|date=2001|publisher=John Wiley & Sons, Ltd|isbn=978-0470015902|language=en|chapter=Bacterial Fermentation|doi=10.1038/npg.els.0001415|chapter-url=http://web.oranim.ac.il/courses/microbiology/Bacterial%20Fermentation%20Nature.pdf|access-date=2014-09-08|archive-date=2014-09-08|archive-url=https://web.archive.org/web/20140908223508/http://web.oranim.ac.il/courses/microbiology/Bacterial%20Fermentation%20Nature.pdf|url-status=dead}}</ref> |

|||

* [[Lactic acid fermentation|Heterolactic acid fermentation]] in which [[Leuconostoc]] bacteria produce lactate + ethanol + {{CO2}} |

|||

* [[Mixed acid fermentation]] where [[Escherichia]] produce ethanol mixed with lactate, acetate, succinate, formate, {{CO2}}, and H<sub>2</sub> |

|||

* [[2,3-butanediol fermentation]] by [[Enterobacter]] producing ethanol, butanediol, lactate, formate, {{CO2}}, and H<sub>2</sub> |

|||

==Gallery== |

|||

<gallery widths=320px> |

|||

Image:Mthomebrew must.JPG|Grapes fermenting during wine production. |

|||

</gallery> |

|||

<gallery> |

<gallery> |

||

Image: |

Image:Alpha-D-Glucopyranose.svg|[[Glucose]] depicted in [[Haworth projection]] |

||

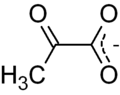

Image:Pyruvate.png|[[Pyruvate]] |

Image:Pyruvate.png|[[Pyruvate]] |

||

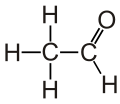

Image:Acetaldehyde-2D-flat. |

Image:Acetaldehyde-2D-flat.svg|[[Acetaldehyde]] |

||

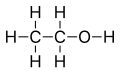

Image:Ethanol-structure.svg|[[Ethanol]] |

Image:Ethanol-structure.svg|[[Ethanol]] |

||

</gallery> |

</gallery> |

||

==Effect of oxygen== |

|||

==Uses== |

|||

Fermentation does not require oxygen. If oxygen is present, some species of yeast (e.g., ''[[Kluyveromyces lactis]]'' or ''[[Kluyveromyces lipolytica]]'') will oxidize [[Pyruvic acid|pyruvate]] completely to carbon dioxide and water in a process called [[cellular respiration]], hence these species of yeast will produce ethanol only in an anaerobic environment (not cellular respiration). This phenomenon is known as the [[Pasteur effect]]. |

|||

[[Image:Bread rolls.JPG|thumb|right|200px|The formation of carbon dioxide - a byproduct of yeast's respiration - causes bread to rise]] |

|||

Ethanol fermentation is responsible for the rising of bread dough. Yeast organisms consume sugars in the dough and produce ethanol and carbon dioxide as waste products. The carbon dioxide forms bubbles in the dough, expanding it into something of a foam. Nearly all the ethanol evaporates from the dough when the bread is baked. |

|||

However, many yeasts such as the commonly used baker's yeast ''[[Saccharomyces cerevisiae]]'' or fission yeast ''[[Schizosaccharomyces pombe]]'' under certain conditions, ferment rather than respire even in the presence of oxygen. In wine making this is known as the counter-Pasteur effect. These yeasts will produce ethanol even under [[Aerobic respiration|aerobic]] conditions, if they are provided with the right kind of nutrition. During batch fermentation, the rate of ethanol production per milligram of cell protein is maximal for a brief period early in this process and declines progressively as ethanol accumulates in the surrounding broth. Studies demonstrate that the removal of this accumulated ethanol does not immediately restore fermentative activity, and they provide evidence that the decline in metabolic rate is due to physiological changes (including possible ethanol damage) rather than to the presence of ethanol. Several potential causes for the decline in fermentative activity have been investigated. Viability remained at or above 90%, internal pH remained near neutrality, and the specific activities of the glycolytic and alcohologenic enzymes (measured in vitro) remained high throughout batch fermentation. None of these factors appears to be causally related to the fall in fermentative activity during batch fermentation. |

|||

The production of all alcoholic beverages, except those produced by [[carbonic maceration]], employs ethanol fermentation by yeast. Wines and brandies are produced by fermentation of the natural sugars present in fruits, especially grapes. Beers, ales, and whiskeys employ fermentation of grain starches that have been converted to sugar by the application of the enzyme, [[amylase]], which is present in grain kernels that have been germinated. Amylase-treated grain or amylase-treated potatoes are fermented for the production of vodka. Fermentation of [[cane sugar]] is the first step in producing rum. In all cases, the fermentation must take place in a vessel that is arranged to allow carbon dioxide to escape, but that prevents outside air from coming in, as exposure to oxygen would prevent the formation of ethanol. |

|||

==Bread baking== |

|||

Similar yeast fermentation of various carbohydrate products is used to produce much of the ethanol used for fuel. |

|||

[[Image:Masa fermentando.JPG|thumb|The formation of carbon dioxide – a byproduct of ethanol fermentation – causes bread to rise.]] |

|||

Ethanol fermentation causes bread dough to rise. Yeast organisms consume sugars in the dough and produce ethanol and carbon dioxide as waste products. The carbon dioxide forms bubbles in the dough, expanding it to a foam. Less than 2% ethanol remains after baking.<ref>{{cite journal|last1=Logan|first1=BK|last2=Distefano|first2=S|title=Ethanol content of various foods and soft drinks and their potential for interference with a breath-alcohol test|journal=Journal of Analytical Toxicology|date=1997|volume=22|issue=3|pages=181–83|pmid=9602932|doi=10.1093/jat/22.3.181|doi-access=}}</ref><ref>{{cite journal|title=The Alcohol Content of Bread|journal=Canadian Medical Association Journal|date=November 1926|volume=16|issue=11|pages=1394–95|pmid=20316063|pmc=1709087}}</ref> |

|||

==Feedstocks for fuel production== |

|||

In a contemporary advancement, a group in Germany has been doing the opposite and converting stale bread into ethanol.<ref>{{cite news|date=2 March 2024 |

|||

The dominant ethanol feedstock in warmer regions is [[sugarcane]].<ref name="usda1">{{cite web|url=http://www.rurdev.usda.gov/rbs/pub/sep06/ethanol.htm|title=Ethanol from Sugar|author=James Jacobs, Ag Economist|publisher=United States Department of Agriculture|accessdate=2007-09-04}}</ref> In temperate regions, this accessibility has been somewhat replicated by selective breeding of the [[sugar beet]].<ref name="usda1"/><ref name="usda2">{{cite web|url=http://www.usda.gov/oce/EthanolSugarFeasibilityReport3.pdf|format=pdf|title=Economic Feasibility of Ethanol Production from Sugar in the United States|accessdate-2007-09-04|publisher=United States Department of Agriculture|month=July | year=2006}}</ref> |

|||

|title= Wie aus altem Brot Alkohol wird|url= https://www.deutschlandfunknova.de/beitrag/bioethanol-wie-aus-altem-brot-alkohol-wird|work= Deutschlandfunk Nova|access-date=7 March 2024}}</ref> |

|||

==Alcoholic beverages== |

|||

In the [[United States]], the main feedstock for the production of ethanol is currently [[Maize#Uses for maize|corn]].<ref name="usda1"/> Approximately 2.8 gallons of ethanol are produced from one bushel of corn (0.42 liter per kilogram). While much of the corn turns into ethanol, some of the corn also yields by-products such as [[distillers grains|DDGS]] (distillers dried grains with solubles) that can be used to fulfill a portion of the diet of livestock. A bushel of corn produces about 18 pounds of DDGS.<ref>{{cite web|url=http://www.ethanolrfa.org/industry/locations/|title=Ethanol Biorefinery Locations|publisher=Renewable Fuels Association|accessdaymonth=21 May|accessyear=2007}}</ref> . Although most of the fermentation plants have been built in corn-producing regions, [[sorghum]] is also an important feedstock for ethanol production in the Plains states. [[Pearl millet]] is showing promise as an ethanol feedstock for the southeastern U.S. |

|||

[[File:Primary fermentation cellar, Budweiser Brewery.jpg|thumb|upright|Primary fermentation cellar, Budweiser Brewery, [[Fort Collins, Colorado]] ]] |

|||

{{main|Alcoholic beverage}} |

|||

Ethanol contained in [[alcoholic beverage]]s is produced by means of fermentation induced by yeast. [[Liquor]]s are distilled from [[grain]]s, [[fruit]]s, [[vegetable]]s, or [[sugar]] that have already gone through alcoholic fermentation. |

|||

In some parts of Europe, particularly France and Italy, wine is used as a feedstock due to a massive oversupply termed ''[[wine lake]]''.<ref>{{cite news|url=http://news.bbc.co.uk/2/hi/europe/5253006.stm|title=Draining France's 'wine lake'|publisher=[[BBC News]]|date=2006-08-10|author=Caroline Wyatt|accessdate=2007-05-21}}</ref> Japan is hoping to use rice wine ([[sake]]) as an ethanol source.<ref>[http://www.npr.org/templates/story/story.php?storyId=10184012 Japan Plans Its Own Green Fuel] by Steve Inskeep. [[Morning Edition]], NPR. May 15, 2007</ref> |

|||

Alcohol products: |

|||

==Ethanol market forecast== |

|||

* Natural sugars present in grapes; |

|||

** Fermented: [[Wine]], [[cider]] and [[perry]] are produced by similar fermentation of natural sugar in [[apple]]s and [[pear]]s, respectively; and other [[fruit wine]]s are produced from the fermentation of the sugars in any other kinds of fruit. |

|||

** Liquors: [[Brandy]] and [[eau de vie|eaux de vie]] (e.g. [[slivovitz]]) are produced by [[distillation]] of these fruit-[[fermented beverage]]s. |

|||

* [[Mead]] is produced by fermentation of the natural sugars present in [[honey]]. |

|||

* Grain starches that have been converted to sugar by the enzyme [[amylase]], which is present in grain kernels that have been [[malting|malted]] (i.e. [[Germination|germinated]]). Other sources of starch (e.g. [[potato]]es and unmalted grain) may be added to the mixture, as the amylase will act on those starches as well. It may also be [[List of amylase induced fermentations|amylase-induce fermented]] with saliva in a few countries. |

|||

** Fermented: [[Beer]] |

|||

** Liquors: [[Whiskey]], and sometimes [[vodka]]. [[Gin]] and related beverages are produced by the addition of flavoring agents to a vodka-like feedstock during distillation. |

|||

* Rice grain starches converted to sugar by the mold ''[[Aspergillus oryzae]]''. |

|||

** Fermented: [[Rice wine]]s (including [[sake]]) |

|||

** Liquors: ''[[Baijiu]]'', ''[[soju]]'', and ''[[shōchū]]'' |

|||

* Sugarcane product [[molasses]]. |

|||

** Liquors: [[Rum]] |

|||

In all cases, fermentation must take place in a vessel (e.g. a [[fermentation lock]]) that allows [[carbon dioxide]] to escape and prevents outside air from coming in. This is because letting in outside air could contaminate the brew due to risk of [[bacteria]] or [[mold]], and a buildup of carbon dioxide could cause the vessel to rupture.{{citation needed|date=March 2019}} |

|||

Main players will be Brazil, USA, EU, and tropical developing countries. EU can currently (2007) produce ethanol in large quantities with a mineral-oil based chemical process for US$0.57 per liter . USA produces ethanol for circa US$0.32 per liter, mainly from corn starch. Brazil produces ethanol for circa US$0.27 per liter, from sugarcane. Tropical developing countries do not produce very large amounts of ethanol yet. |

|||

==Feedstocks for fuel production== |

|||

Brazil is the largest producer, but it will not be able to meet EU's needs for many years to come, |

|||

Yeast fermentation of various carbohydrate products is also used to produce the ethanol that is added to [[gasoline]]. |

|||

assuming that it will expand ethanol production at maximum possible rate. |

|||

USA is expected to become self-supplying (to avoid high oil prices), |

|||

but is not expected to become a major exporter. |

|||

EU also wants to avoid high oil prices, |

|||

and is starting to require a minimum ethanol percentage in automobile fuels, |

|||

so it wants to import ethanol. |

|||

Ethanol can be made from mineral oil or from sugars or starches, cheapest of which are starches, |

|||

and starchy crop with highest energy content per acre is cassava, |

|||

which grows in tropical countries. |

|||

The dominant ethanol feedstock in warmer regions is [[sugarcane]].<ref name="usda1">{{cite web|url=http://www.rurdev.usda.gov/rbs/pub/sep06/ethanol.htm|title=Ethanol from Sugar|author=James Jacobs, Ag Economist|publisher=United States Department of Agriculture|access-date=2007-09-04|url-status=dead|archive-url=https://web.archive.org/web/20070910023203/http://www.rurdev.usda.gov/rbs/pub/sep06/ethanol.htm|archive-date=2007-09-10}}</ref> In temperate regions, [[Corn ethanol|corn]] or [[sugar beet]]s are used.<ref name="usda1"/><ref name="usda2">{{cite web|url=http://www.usda.gov/oce/EthanolSugarFeasibilityReport3.pdf|title=Economic Feasibility of Ethanol Production from Sugar in the United States|access-date=2007-09-04|publisher=United States Department of Agriculture|date=July 2006 |archive-url = https://web.archive.org/web/20070815063506/http://www.usda.gov/oce/EthanolSugarFeasibilityReport3.pdf <!-- Bot retrieved archive --> |archive-date = 2007-08-15}}</ref> |

|||

Thailand already had a large cassava industry in the 1990s, |

|||

for use as cattle food and as cheap admixture to wheat flour; |

|||

Nigeria and Ghana are already establishing cassava-to-ethanol plants ; Brazil is doing that too (sugarcane and cassava grow on very different types of soil) ; |

|||

and so are many other countries. |

|||

In the United States, the main feedstock for the production of ethanol is currently corn.<ref name="usda1"/> Approximately 2.8 gallons of ethanol are produced from one bushel of corn (0.42 liter per kilogram). While much of the corn turns into ethanol, some of the corn also yields by-products such as [[distillers grains|DDGS]] (distillers dried grains with solubles) that can be used as feed for livestock. A bushel of corn produces about 18 pounds of DDGS (320 kilograms of DDGS per metric ton of maize).<ref>{{cite web|url=http://www.ethanolrfa.org/industry/locations/|title=Ethanol Biorefinery Locations|publisher=Renewable Fuels Association|access-date=21 May 2007 |archive-url = https://web.archive.org/web/20070430004536/http://www.ethanolrfa.org/industry/locations/ <!-- Bot retrieved archive --> |archive-date = 30 April 2007}}</ref> Although most of the fermentation plants have been built in corn-producing regions, [[sorghum]] is also an important feedstock for ethanol production in the Plains states. [[Pearl millet]] is showing promise as an ethanol feedstock for the southeastern U.S. and the potential of [[duckweed]] is being studied.<ref>{{Cite web|url=https://projects.ncsu.edu/cals/agcomm/magazine/latest-news/Tiny-super-plant-can-clean-up-hog-farms-and-be-used-for-ethanol-production.html|archive-url=https://web.archive.org/web/20200718202846/https://projects.ncsu.edu/cals/agcomm/magazine/latest-news/Tiny-super-plant-can-clean-up-hog-farms-and-be-used-for-ethanol-production.html|url-status=dead|archive-date=July 18, 2020|title=Tiny super-plant can clean up hog farms and be used for ethanol production|website=projects.ncsu.edu|language=en-US|access-date=2018-01-18}}</ref> |

|||

EU expects that combined effect of increasing ethanol production will be able to meet its needs in 2012. Therefore it is expect that in 2012 price of ethanol will drop from maybe US$0.42 to maybe US$0.30 (FOB Africa). Production of ethanol from cassava is currently economically feasible when crude oil prices are above US$120 per barrel. |

|||

In some parts of Europe, particularly France and Italy, [[grapes]] have become a ''de facto'' feedstock for fuel ethanol by the [[distillation]] of surplus [[wine]].<ref>{{cite news|url=http://news.bbc.co.uk/2/hi/europe/5253006.stm|title=Draining France's 'wine lake'|work=[[BBC News]]|date=2006-08-10|author=Caroline Wyatt|author-link=Caroline Wyatt|access-date=2007-05-21}}</ref> Surplus sugary drinks may also be used.<ref>{{cite news|url=https://qz.com/1135119/where-unsellable-wine-goes-to-die-and-become-fuel-for-your-cars-gas-tank/|title=That unsold bottle of Merlot is probably winding up in your gas tank|last1=Capone|first1=John|date=21 November 2017|work=[[Quartz (publication)|Quartz]]|access-date=21 November 2017}}</ref> In Japan, it has been proposed to use rice normally made into [[sake]] as an ethanol source.<ref>[https://www.npr.org/templates/story/story.php?storyId=10184012 Japan Plans Its Own Green Fuel] by Steve Inskeep. NPR Morning Edition, May 15, 2007</ref> |

|||

New varieties of cassava are being developed, so future situation remains uncertain. |

|||

Currently, cassava can yield more than 40 tons per hectare (with irrigation and fertilizer), |

|||

and from a ton of cassava roots, circa 200 liter of ethanol can be produced (assuming cassava with 22% starch content), and a liter of ethanol contains circa 10.7 [[megajoule|MJ]] of energy. Overall energy efficiency of cassava-root to ethanol conversion is circa 32%. |

|||

===Cassava as ethanol feedstock=== |

|||

Cassava plants can grow in poor soils, are drought resistant, and need a minimum temperature of 17 °C. They can use solar radiation up to 300 W/m² (equivalent to lightly clouded tropical sky), and optimum water use is 100 to 150 cm (slightly less than rainfall in rain forest). |

|||

Ethanol can be made from [[mineral oil]] or from sugars or starches. Starches are cheapest. The starchy crop with highest energy content per acre is [[cassava]], which grows in tropical countries. |

|||

For compensating for nutrients taken up, Cassava's fertilizer demand is (in kilograms of nutrient per ton{{vague|date=March 2008}} cassava): N:21, P:10, K:42, Ca:7, Mg:4 , so if fertilizer prices go up, so does ethanol price. |

|||

Thailand already had a large cassava industry in the 1990s, for use as cattle feed and as a cheap admixture to wheat flour. Nigeria and Ghana are already establishing cassava-to-ethanol plants. Production of ethanol from cassava is currently economically feasible when crude oil prices are above US$120 per barrel. |

|||

Starch price (food-quality starch from Thailand) is circa 0.22 US$/kg, and from 1 kg starch, 0.9 liter of ethanol can be produced, so, producer price would be 0.24 US$/liter plus cost of conversion from starch to ethanol. |

|||

A US$10 million conversion plant can convert circa 80 million liters per year, so total cost of ethanol from cassava currently is near USA's production price. Due to improvements being made in this relatively new industry, producer price would become lower, probably near that of Brazil, and maybe even lower than that. |

|||

New varieties of cassava are being developed, so the future situation remains uncertain. |

|||

Yeast used for processing cassava is ''Endomycopsis fibuligera'', sometimes used together with bacterium ''Zymomonas mobilis''. |

|||

Currently, cassava can yield between 25 and 40 tonnes per hectare (with irrigation and fertilizer),<ref>{{Cite web |url=http://agro2.com/our-cassava-products/ethanol/ |title=Agro2: Ethanol From Cassava |access-date=2010-08-25 |archive-url=http://arquivo.pt/wayback/20160519032835/http://agro2.com/our-cassava-products/ethanol/ |archive-date=2016-05-19 |url-status=dead }}</ref> and from a tonne of cassava roots, circa 200 liters of ethanol can be produced (assuming cassava with 22% starch content). A liter of ethanol contains circa 21.46<ref>Pimentel, D. (Ed.) (1980). CRC Handbook of energy utilization in agriculture. (Boca Raton: CRC Press)</ref> [[megajoule|MJ]] of energy. The overall [[Energy efficiency (physics)|energy efficiency]] of cassava-root to ethanol conversion is circa 32%. |

|||

The yeast used for processing cassava is ''Endomycopsis fibuligera'', sometimes used together with bacterium ''Zymomonas mobilis''. |

|||

Most of this information can be found on FAO's website. |

|||

==Byproducts of fermentation== |

|||

Ethanol fermentation produces unharvested byproducts such as heat, carbon dioxide, food for livestock, water, methanol, fuels, fertilizer and alcohols.<ref name="afh">{{cite book|title=The Alcohol Fuel Handbook|author=Lynn Ellen Doxon|publisher=InfinityPublishing.com|isbn=978-0-7414-0646-0|year=2001|url-access=registration|url=https://archive.org/details/alcoholfuelhandb0000doxo}}{{page?|date=October 2021}}</ref> The cereal unfermented solid residues from the fermentation process, which can be used as livestock feed or in the production of [[biogas]], are referred to as [[Distillers grains]] and sold as WDG, ''Wet Distiller's grains'', and DDGS, ''Dried Distiller's Grains with Solubles'', respectively. |

|||

== Microbes used in ethanol fermentation == |

== Microbes used in ethanol fermentation == |

||

* [[Yeast]] |

* [[Yeast]] |

||

**[[Saccharomyces cerevisiae]] |

|||

* [[Zymomonas mobilis]] |

|||

**[[Schizosaccharomyces]] |

|||

* [[Zymomonas mobilis]] (a bacterium) |

|||

==See also== |

==See also== |

||

{{div col|colwidth=30em}} |

|||

*[[Anaerobic respiration]] |

|||

* [[Anaerobic respiration]] |

|||

*[[Cellulose]] |

|||

*[[Cellular respiration]] |

* [[Cellular respiration]] |

||

* [[Cellulose]] |

|||

*[[Fermentation (biochemistry)]] |

|||

* [[Fermentation (wine)]] |

* [[Fermentation (wine)]] |

||

* [[Yeast in winemaking]] |

|||

* [[Auto-brewery syndrome]] |

|||

* [[Tryptophol]], a chemical compound found in wine<ref>{{Cite journal | last1 = Gil | first1 = C. | last2 = Gómez-Cordovés | first2 = C. | doi = 10.1016/0308-8146(86)90009-9 | title = Tryptophol content of young wines made from Tempranillo, Garnacha, Viura and Airén grapes | journal = Food Chemistry | volume = 22 | pages = 59–65 | year = 1986 }}</ref> or in beer<ref>{{cite journal | doi = 10.1002/j.2050-0416.1973.tb03541.x| title = Tryptophol, Tyrosol and Phenylethanol-The Aromatic Higher Alcohols in Beer| journal = Journal of the Institute of Brewing| volume = 79| issue = 4| pages = 283–88| year = 1973| last1 = Szlavko| first1 = Clara M| doi-access = free}}</ref> as a secondary product of alcoholic fermentation<ref>{{Cite journal |

|||

| last1 = Ribéreau-Gayon | first1 = P. |

|||

| last2 = Sapis | first2 = J. C. |

|||

| title = On the presence in wine of tyrosol, tryptophol, phenylethyl alcohol and gamma-butyrolactone, secondary products of alcoholic fermentation |

|||

| journal = Comptes Rendus de l'Académie des Sciences, Série D |

|||

| volume = 261 |

|||

| issue = 8 |

|||

| pages = 1915–16 |

|||

| year = 2019 |

|||

| pmid = 4954284 |

|||

}} (Article in French)</ref> (a product also known as [[congener (alcohol)|congener]]) |

|||

{{div col end}} |

|||

==References== |

==References== |

||

{{Reflist|30em}} |

|||

<references/> |

|||

{{Metabolism}} |

|||

{{Carbohydrate metabolism}} |

|||

{{Authority control}} |

|||

{{DEFAULTSORT:Ethanol Fermentation}} |

|||

[[Category:Cellular respiration]] |

|||

[[Category:Fermentation]] |

[[Category:Fermentation]] |

||

[[Category:Ethanol]] |

|||

{{Link FA|de}} |

|||

[[bs:Alkoholno vrenje]] |

|||

[[da:Alkoholisk fermentering]] |

|||

[[de:Alkoholische Gärung]] |

|||

[[es:Fermentación alcohólica]] |

|||

[[fr:Fermentation alcoolique]] |

|||

[[it:Fermentazione alcolica]] |

|||

[[he:תסיסה כהלית]] |

|||

[[lv:Alkoholiskā rūgšana]] |

|||

[[nl:Gisting]] |

|||

[[ja:アルコール発酵]] |

|||

[[pl:Fermentacja alkoholowa]] |

|||

[[pt:Fermentação alcoólica]] |

|||

[[tr:Alkol fermantasyonu]] |

|||

[[uk:Спиртове бродіння]] |

|||

Latest revision as of 07:03, 5 June 2024

Ethanol fermentation, also called alcoholic fermentation, is a biological process which converts sugars such as glucose, fructose, and sucrose into cellular energy, producing ethanol and carbon dioxide as by-products. Because yeasts perform this conversion in the absence of oxygen, alcoholic fermentation is considered an anaerobic process. It also takes place in some species of fish (including goldfish and carp) where (along with lactic acid fermentation) it provides energy when oxygen is scarce.[1]

Ethanol fermentation is the basis for alcoholic beverages, ethanol fuel and bread dough rising.

Biochemical process of fermentation of sucrose

[edit]

The chemical equations below summarize the fermentation of sucrose (C12H22O11) into ethanol (C2H5OH). Alcoholic fermentation converts one mole of glucose into two moles of ethanol and two moles of carbon dioxide, producing two moles of ATP in the process.

- C6H12O6 + 2 ADP + 2 Pi → 2 C2H5OH + 2 CO2 + 2 ATP

Sucrose is a sugar composed of a glucose linked to a fructose. In the first step of alcoholic fermentation, the enzyme invertase cleaves the glycosidic linkage between the glucose and fructose molecules.

Next, each glucose molecule is broken down into two pyruvate molecules in a process known as glycolysis.[2] Glycolysis is summarized by the equation:

- C6H12O6 + 2 ADP + 2 Pi + 2 NAD+ → 2 CH3COCOO− + 2 ATP + 2 NADH + 2 H2O + 2 H+

CH3COCOO− is pyruvate, and Pi is inorganic phosphate. Finally, pyruvate is converted to ethanol and CO2 in two steps, regenerating oxidized NAD+ needed for glycolysis:

- 1. CH3COCOO− + H+ → CH3CHO + CO2

catalyzed by pyruvate decarboxylase

- 2. CH3CHO + NADH + H+ → C2H5OH + NAD+

This reaction is catalyzed by alcohol dehydrogenase (ADH1 in baker's yeast).[3]

As shown by the reaction equation, glycolysis causes the reduction of two molecules of NAD+ to NADH. Two ADP molecules are also converted to two ATP and two water molecules via substrate-level phosphorylation.

Related processes

[edit]Fermentation of sugar to ethanol and CO2 can also be done by Zymomonas mobilis, however the path is slightly different since formation of pyruvate does not happen by glycolysis but instead by the Entner–Doudoroff pathway. Other microorganisms can produce ethanol from sugars by fermentation but often only as a side product. Examples are[4]

- Heterolactic acid fermentation in which Leuconostoc bacteria produce lactate + ethanol + CO2

- Mixed acid fermentation where Escherichia produce ethanol mixed with lactate, acetate, succinate, formate, CO2, and H2

- 2,3-butanediol fermentation by Enterobacter producing ethanol, butanediol, lactate, formate, CO2, and H2

Gallery

[edit]-

Grapes fermenting during wine production.

-

Glucose depicted in Haworth projection

Effect of oxygen

[edit]Fermentation does not require oxygen. If oxygen is present, some species of yeast (e.g., Kluyveromyces lactis or Kluyveromyces lipolytica) will oxidize pyruvate completely to carbon dioxide and water in a process called cellular respiration, hence these species of yeast will produce ethanol only in an anaerobic environment (not cellular respiration). This phenomenon is known as the Pasteur effect.

However, many yeasts such as the commonly used baker's yeast Saccharomyces cerevisiae or fission yeast Schizosaccharomyces pombe under certain conditions, ferment rather than respire even in the presence of oxygen. In wine making this is known as the counter-Pasteur effect. These yeasts will produce ethanol even under aerobic conditions, if they are provided with the right kind of nutrition. During batch fermentation, the rate of ethanol production per milligram of cell protein is maximal for a brief period early in this process and declines progressively as ethanol accumulates in the surrounding broth. Studies demonstrate that the removal of this accumulated ethanol does not immediately restore fermentative activity, and they provide evidence that the decline in metabolic rate is due to physiological changes (including possible ethanol damage) rather than to the presence of ethanol. Several potential causes for the decline in fermentative activity have been investigated. Viability remained at or above 90%, internal pH remained near neutrality, and the specific activities of the glycolytic and alcohologenic enzymes (measured in vitro) remained high throughout batch fermentation. None of these factors appears to be causally related to the fall in fermentative activity during batch fermentation.

Bread baking

[edit]

Ethanol fermentation causes bread dough to rise. Yeast organisms consume sugars in the dough and produce ethanol and carbon dioxide as waste products. The carbon dioxide forms bubbles in the dough, expanding it to a foam. Less than 2% ethanol remains after baking.[5][6]

In a contemporary advancement, a group in Germany has been doing the opposite and converting stale bread into ethanol.[7]

Alcoholic beverages

[edit]

Ethanol contained in alcoholic beverages is produced by means of fermentation induced by yeast. Liquors are distilled from grains, fruits, vegetables, or sugar that have already gone through alcoholic fermentation.

Alcohol products:

- Natural sugars present in grapes;

- Fermented: Wine, cider and perry are produced by similar fermentation of natural sugar in apples and pears, respectively; and other fruit wines are produced from the fermentation of the sugars in any other kinds of fruit.

- Liquors: Brandy and eaux de vie (e.g. slivovitz) are produced by distillation of these fruit-fermented beverages.

- Mead is produced by fermentation of the natural sugars present in honey.

- Grain starches that have been converted to sugar by the enzyme amylase, which is present in grain kernels that have been malted (i.e. germinated). Other sources of starch (e.g. potatoes and unmalted grain) may be added to the mixture, as the amylase will act on those starches as well. It may also be amylase-induce fermented with saliva in a few countries.

- Rice grain starches converted to sugar by the mold Aspergillus oryzae.

- Fermented: Rice wines (including sake)

- Liquors: Baijiu, soju, and shōchū

- Sugarcane product molasses.

- Liquors: Rum

In all cases, fermentation must take place in a vessel (e.g. a fermentation lock) that allows carbon dioxide to escape and prevents outside air from coming in. This is because letting in outside air could contaminate the brew due to risk of bacteria or mold, and a buildup of carbon dioxide could cause the vessel to rupture.[citation needed]

Feedstocks for fuel production

[edit]Yeast fermentation of various carbohydrate products is also used to produce the ethanol that is added to gasoline.

The dominant ethanol feedstock in warmer regions is sugarcane.[8] In temperate regions, corn or sugar beets are used.[8][9]

In the United States, the main feedstock for the production of ethanol is currently corn.[8] Approximately 2.8 gallons of ethanol are produced from one bushel of corn (0.42 liter per kilogram). While much of the corn turns into ethanol, some of the corn also yields by-products such as DDGS (distillers dried grains with solubles) that can be used as feed for livestock. A bushel of corn produces about 18 pounds of DDGS (320 kilograms of DDGS per metric ton of maize).[10] Although most of the fermentation plants have been built in corn-producing regions, sorghum is also an important feedstock for ethanol production in the Plains states. Pearl millet is showing promise as an ethanol feedstock for the southeastern U.S. and the potential of duckweed is being studied.[11]

In some parts of Europe, particularly France and Italy, grapes have become a de facto feedstock for fuel ethanol by the distillation of surplus wine.[12] Surplus sugary drinks may also be used.[13] In Japan, it has been proposed to use rice normally made into sake as an ethanol source.[14]

Cassava as ethanol feedstock

[edit]Ethanol can be made from mineral oil or from sugars or starches. Starches are cheapest. The starchy crop with highest energy content per acre is cassava, which grows in tropical countries.

Thailand already had a large cassava industry in the 1990s, for use as cattle feed and as a cheap admixture to wheat flour. Nigeria and Ghana are already establishing cassava-to-ethanol plants. Production of ethanol from cassava is currently economically feasible when crude oil prices are above US$120 per barrel.

New varieties of cassava are being developed, so the future situation remains uncertain. Currently, cassava can yield between 25 and 40 tonnes per hectare (with irrigation and fertilizer),[15] and from a tonne of cassava roots, circa 200 liters of ethanol can be produced (assuming cassava with 22% starch content). A liter of ethanol contains circa 21.46[16] MJ of energy. The overall energy efficiency of cassava-root to ethanol conversion is circa 32%.

The yeast used for processing cassava is Endomycopsis fibuligera, sometimes used together with bacterium Zymomonas mobilis.

Byproducts of fermentation

[edit]Ethanol fermentation produces unharvested byproducts such as heat, carbon dioxide, food for livestock, water, methanol, fuels, fertilizer and alcohols.[17] The cereal unfermented solid residues from the fermentation process, which can be used as livestock feed or in the production of biogas, are referred to as Distillers grains and sold as WDG, Wet Distiller's grains, and DDGS, Dried Distiller's Grains with Solubles, respectively.

Microbes used in ethanol fermentation

[edit]- Yeast

- Zymomonas mobilis (a bacterium)

See also

[edit]- Anaerobic respiration

- Cellular respiration

- Cellulose

- Fermentation (wine)

- Yeast in winemaking

- Auto-brewery syndrome

- Tryptophol, a chemical compound found in wine[18] or in beer[19] as a secondary product of alcoholic fermentation[20] (a product also known as congener)

References

[edit]- ^ Aren van Waarde; G. Van den Thillart; Maria Verhagen (1993). "Ethanol Formation and pH-Regulation in Fish". Surviving Hypoxia. pp. 157−70. hdl:11370/3196a88e-a978-4293-8f6f-cd6876d8c428. ISBN 978-0849342264.

- ^ Stryer, Lubert (1975). Biochemistry. W. H. Freeman and Co. ISBN 978-0716701743.[page needed]

- ^ Raj SB, Ramaswamy S, Plapp BV (2014). "Yeast alcohol dehydrogenase structure and catalysis". Biochemistry. 53 (36): 5791–6503. doi:10.1021/bi5006442. PMC 4165444. PMID 25157460.

- ^ Müller, Volker (2001). "Bacterial Fermentation" (PDF). eLS. John Wiley & Sons, Ltd. doi:10.1038/npg.els.0001415. ISBN 978-0470015902. Archived from the original (PDF) on 2014-09-08. Retrieved 2014-09-08.

- ^ Logan, BK; Distefano, S (1997). "Ethanol content of various foods and soft drinks and their potential for interference with a breath-alcohol test". Journal of Analytical Toxicology. 22 (3): 181–83. doi:10.1093/jat/22.3.181. PMID 9602932.

- ^ "The Alcohol Content of Bread". Canadian Medical Association Journal. 16 (11): 1394–95. November 1926. PMC 1709087. PMID 20316063.

- ^ "Wie aus altem Brot Alkohol wird". Deutschlandfunk Nova. 2 March 2024. Retrieved 7 March 2024.

- ^ a b c James Jacobs, Ag Economist. "Ethanol from Sugar". United States Department of Agriculture. Archived from the original on 2007-09-10. Retrieved 2007-09-04.

- ^ "Economic Feasibility of Ethanol Production from Sugar in the United States" (PDF). United States Department of Agriculture. July 2006. Archived from the original (PDF) on 2007-08-15. Retrieved 2007-09-04.

- ^ "Ethanol Biorefinery Locations". Renewable Fuels Association. Archived from the original on 30 April 2007. Retrieved 21 May 2007.

- ^ "Tiny super-plant can clean up hog farms and be used for ethanol production". projects.ncsu.edu. Archived from the original on July 18, 2020. Retrieved 2018-01-18.

- ^ Caroline Wyatt (2006-08-10). "Draining France's 'wine lake'". BBC News. Retrieved 2007-05-21.

- ^ Capone, John (21 November 2017). "That unsold bottle of Merlot is probably winding up in your gas tank". Quartz. Retrieved 21 November 2017.

- ^ Japan Plans Its Own Green Fuel by Steve Inskeep. NPR Morning Edition, May 15, 2007

- ^ "Agro2: Ethanol From Cassava". Archived from the original on 2016-05-19. Retrieved 2010-08-25.

- ^ Pimentel, D. (Ed.) (1980). CRC Handbook of energy utilization in agriculture. (Boca Raton: CRC Press)

- ^ Lynn Ellen Doxon (2001). The Alcohol Fuel Handbook. InfinityPublishing.com. ISBN 978-0-7414-0646-0.[page needed]

- ^ Gil, C.; Gómez-Cordovés, C. (1986). "Tryptophol content of young wines made from Tempranillo, Garnacha, Viura and Airén grapes". Food Chemistry. 22: 59–65. doi:10.1016/0308-8146(86)90009-9.

- ^ Szlavko, Clara M (1973). "Tryptophol, Tyrosol and Phenylethanol-The Aromatic Higher Alcohols in Beer". Journal of the Institute of Brewing. 79 (4): 283–88. doi:10.1002/j.2050-0416.1973.tb03541.x.

- ^ Ribéreau-Gayon, P.; Sapis, J. C. (2019). "On the presence in wine of tyrosol, tryptophol, phenylethyl alcohol and gamma-butyrolactone, secondary products of alcoholic fermentation". Comptes Rendus de l'Académie des Sciences, Série D. 261 (8): 1915–16. PMID 4954284. (Article in French)

![{\displaystyle {\ce {C12H22O11{}+H2O->[{\text{Invertase}}]2C6H12O6}}}](https://wikimedia.org/enwiki/api/rest_v1/media/math/render/svg/d5b821ec8da4bd9dd7f6dec5ee66a5d04390a13c)