User:HJVerhagen/sandbox: Difference between revisions

HJVerhagen (talk | contribs) |

D McParland (talk | contribs) Intro first draft Tags: Visual edit Mobile edit Mobile web edit |

||

| Line 1: | Line 1: | ||

[[File:Veerse Gatdam.jpg|thumb|The Veerse Gatdam]]''' |

[[File:Veerse Gatdam.jpg|thumb|The Veerse Gatdam]]In coastal and environmental engineering, '''the closure of tidal inlets''' entails the deliberate prevention of the entry of [[Seawater|seawate]]<nowiki/>r into inland areas through the use of fill material and the construction of barriers. The aim of such closures is usually to safeguard inland regions from flooding, thereby protecting [[Ecology|ecological]] integrity and reducing potential harm to human settlements and agricultural areas. |

||

The complexity of inlet closure varies significantly with the size of the [[estuary]] involved. For smaller estuaries, which may naturally desiccate at low tide, the process can be relatively straightforward. However, the management of larger estuaries demands a sophisticated blend of technical expertise, encapsulating [[Fluid dynamics|hydrodynamics]], [[sediment transport]], and the potential ecological consequences of such interventions. The development of knowledge around such closures over time reflects a concerted effort to balance [[Flood control|flood defence]] mechanisms with [[environmental stewardship]], leading to the development of both traditional and technologically advanced solutions. |

|||

== Purpose of a closure == |

== Purpose of a closure == |

||

Revision as of 00:26, 3 March 2024

In coastal and environmental engineering, the closure of tidal inlets entails the deliberate prevention of the entry of seawater into inland areas through the use of fill material and the construction of barriers. The aim of such closures is usually to safeguard inland regions from flooding, thereby protecting ecological integrity and reducing potential harm to human settlements and agricultural areas.

The complexity of inlet closure varies significantly with the size of the estuary involved. For smaller estuaries, which may naturally desiccate at low tide, the process can be relatively straightforward. However, the management of larger estuaries demands a sophisticated blend of technical expertise, encapsulating hydrodynamics, sediment transport, and the potential ecological consequences of such interventions. The development of knowledge around such closures over time reflects a concerted effort to balance flood defence mechanisms with environmental stewardship, leading to the development of both traditional and technologically advanced solutions.

Purpose of a closure

Main purposes of closing a tidal inlet are:

- land reclamation

- shortening the length of sea defence

- creating of fresh water reservoir

- creation of a tidal energy-basin

- creation of a fixed level harbour dock

- creating a construction dock

- providing a road or rail connection

- repair of a dike breach

- creating fish ponds

In the past, inlets were mainly closed for the purposes of land reclamation and controlling the water levels on marshy land. In both cases this was linked to agricultural development. It is typical of these damming activities that the control of river and storm surge levels becomes essential. Follow-up action, like the repair of dike breaches has been necessary throughout the ages. The other purposes mentioned, like generation of tidal energy, harbour and construction docks, dams for road or rail connection and fish ponds are incidental works and have a smaller impact on the surroundings. Today, since the quality of life is becoming an important aspect for society, certainly in the industrially developed countries, damming activities are initiated to serve various other purposes. These include the creation of fresh water storage basins, the prevention of water pollution in designated areas, the provision of recreational facilities and the counteraction of salt intrusion or groundwater flow.

Side effects

Various possible side-effects could be (dependent on circumstances):

- change of tide (amplitude, flows) at the seaward side of the dam

- change in bar and gully topography, outside the dam

- disappearance of tides on the inner side of the dam

- change in groundwater level in adjoining areas

- alteration of drainage capacity for adjoining areas

- loss of fish and vegetation species

- loss of breeding and feeding areas for water birds

- rotting processes during change in vegetation and fauna

- stratification of water quality in stagnant reservoir

- accumulation of sediments in the reservoir

- impact on facilities for shipping

- impact on recreation and leisure pursuits

- change in professional occupation (fishery, navigation)

- social and cultural impacts

Examples of closure works

Netherlands (history)

The Netherlands has many places that end in .....dam. These places were created at the location of a dam in a tidal river. Very well known are Amsterdam (dam in the Amstel) and Rotterdam (dam in the Rotte). But in some places this is a bit more unclear, such as Maasdam. This village is located at the site of a dam in the course of the Maas river from before 1300. This dam in the then Maas allowed the construction of the Grote Hollandse Waard, which was lost again during the St. Elizabeth's flood (1421).[1] If at low tide the closing gap was not so large and quite shallow, an auxiliary bridge could be built over it and heavy sod (shorkloeten), sandbags or clay lumps were poured into it with wheelbarrows.

A technique that was also widely used was called “opzinken” (literally: sinking up). This involves sinking a fascine mattress, filling it with sand and stabilizing it with some ballast stone. The next sinking section is then sunk on top. This is repeated until the dam is so high that no further mattress can be placed on it. The flow has then reduced so much that the dam can be completed with sand and clay.[2] For example, the damming of the Sloe (for the construction of the railway to Middelburg in 1879) was carried out in this way.

It was known quite early that during a closure the flow velocity in the closure gap increased, and that this caused erosion of the soil. That is why people often placed a bottom protection around the closing gap. The dimensions and heaviness of such a deposit could not be calculated. This was entirely based on experience. Until 1953, to close dike breaches in the tidal area, it was not possible to always close the breach at the location of the original breach, because the current velocities were too great there. In those cases, a new dike was built further inland; Although this was a much longer process, it was easier to conclude. An extreme case (and also the last in the Netherlands) was the closure of the breaches at Schelphoek after the 1953 flood.

Netherlands (modern)

Larger dams in more modern times were often motivated by both the need to protect the hinterland and the creation of new agricultural land.

Currents arise in the mouth of an inlet as a result of the filling (high tide) and emptying (ebb) of the basin due to the tidal action at sea. The current speeds in the mouth of a tidal basin depend on the tidal range, the tidal curve, the size of the tidal basin (the so-called storage area) and the size of the flow profile at that location. The tidal range is not constant along the Dutch coast. It is smallest near Den Helder (approximately 1.5 m) and largest off the Zeeland coast, namely 2 to 3 m, while at the back of the Oosterschelde and Westerschelde it increases to 4 to 5 m.

In a tidal basin with a bottom of loosely packed material, current channels are formed, which can change position due to the constantly changing direction and speed of currents. Where the flow is strongest, the channels are scoured the deepest, in the Oosterschelde sometimes up to 45 m deep, while sandbanks form between the channels, which sometimes dry up at low tide.

The channel system that has been formed in a tidal area along the natural path is in most cases approximately in equilibrium. This concerns the flow speed on the one hand and the total flow profile on the other. When breaches in dikes are closed, on the other hand, equilibrium is usually not yet reached at the time of closure. For example, after the storm surge in 1953, rapid intervention in a large number of breaches made it possible to limit the extent of the erosion. For the construction of a dam in the mouth of an inlet, works are being carried out that reduce the flow profile. Without special measures, increased flow velocities caused by this will cause scouring. To prevent this, the bottom and sides of the channels will generally be secured in advance using bottom protection. An exception to this may arise in those cases where the surface area of the tidal basin is reduced in advance by Compartmentalisation dams.

A tidal channel closure can generally be divided into the following four phases:

- A preparatory phase without a strong narrowing of the flow profile (reduction to 80 to 90% of the flow profile). In this phase, dam sections can be constructed in the shallow areas and soil protection in the channels.

- Usually a silli is then built up, which serves as a foundation for the closing quay. This sill can have the function of distributing the pressure of the closing quay on the subsoil and/or as a filter between bottom protection and the closing means. The closing gap constructed during this phase must be so wide that it is able to allow the ebb and flow currents to pass through without the sill and the bottom and bank defenses being impermissibly affected.

- The actual closure where the final closing gap is closed.

- The final phase in which the dike is built over and around the temporary dam.

Under certain circumstances a different construction method is possible; For example, during a sand closure, dumping capacity is deployed in such a way that more material is introduced per tide than can be carried away by the current. In that case, no soil protection is usually required.

When the Zuiderzee was closed in 1932, it was still possible to control the current with boulder clay. Because the tidal difference there was only 1 m, the flow velocities in the closing gap did not become so high that other materials had to be used. Many closure methods have been applied in the Delta area, both on a smaller and large scale. The closure methods to be used for the closing gap are always highly dependent on a large number of preconditions. In addition to the hydraulic and soil mechanical preconditions, the available resources also play a role in this choice. The available resources concern materials, equipment, manpower, finances and experience. An enormous development took place after the Second World War. The experiences gained during the dike repair on Walcheren in 1945, the closure of the Brielse Maas in 1950 and the Braakman in 1952 and the closure gaps after the storm surge disaster of 1953 were an essential part of the choice of closure methods to be used for the first Delta dams. .Until the completion of the Brouwersdam in 1971, the choice of closure method to be used was almost exclusively based on technical factors. Environmental and fisheries considerations played an equally important role in the choice of the closure method for the Markiezaatskade near Bergen op Zoom, the Philipsdam and Oesterdam and the storm surge barrier in the Oosterschelde. This includes, for example, the season in which tidal organisms die and the salinity control during the closure organizations. These factors are especially important because they determine the initial situation for the newly created basin.

| Length (m) | Completion | Type of dam | Method | |

|---|---|---|---|---|

| Zandkreek | 830 | 1960 | Secondary dam | Two closed caissons |

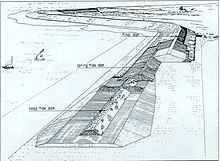

| Veerse Gat | 2800 | 1961 | Primary damdam | Sluice caissons |

| Grevelingendam | 6000 | 1965 | Compartmentalisation dam | Cable car |

| Volkerakdam | 5000 | 1969 | Compartmentalisation dam | Sluice caisson |

| Brouwersdam | 6000 | 1971 | Primary dam | Sluice caissons and cable car |

| Haringlietdam | 5000 | 1971 | Primary dam and discharge sluice | Cable car |

| Oesterdam | 10500 | 1986 | Compartmentalisation dam | Sand closure |

| Philipsdam | 6000 | 1987 | Compartmentalisation dam | Sand closure |

Closures in Germany

In the north-west of Germany also a number of closure works were realised. The original purpose of the closures was land reclamation and safety against flooding. In a later phase the importance moved to safety and ecological protection. Closures were made in Meldorf (1978),[4] Nordstrander Bucht (Husum, 1987) and Leyhörn (Greetsiel, 1991).

Around 1975 enhanced world views regarding ecological importance altered the design of closures. Because of this in the north of Germany a number of closures were completed in a different way than planned. For example it was planned to dam the full Leybucht near Greetsiel, but eventually only a small part was closed, just sufficient to guarantee safety and water management requirements. As a result closure of the remains area was no technical problem anymore. A discharge sluice and navigation lock was build, which had sufficient capacity to prevent currents in the closure gap of the dam.

Closures in South Korea

In Korea in the sixties there was an enormous shortage of agricultural land. So, large reclamation works including closure dams were planned. Execution took place between 1975 and 1995. The experience from the Netherlands was used in detail. Also in Korea a change in attitude towards closing works happened. Therefore the plans for the Hwaong and Saemangeum were considerably delayed, and also adapted.

| Name | Length (km) | Tidal range (m) | Area (km2) | Closing date |

|---|---|---|---|---|

| Saemangeum | 29 | 7.0 | 400 | April 2006 |

| Hwaong | 19 | 9.4 | 62 | Mar 2002 |

| Sihwa | 13 | 9.3 | 173 | Jan 1994 |

| Sukmun | 11 | 9.4 | 37 | Nov 1991 |

| Busa | 3 | 7.5 | 13 | Mar1988 |

| Yongsan | 4 | 5.6 | 10 | Feb 1983 |

| Sabkyo | 3 | 10.4 | 28 | Mar 1977 |

Closures in Bangladesh

Already many years in Bangladesh creeks were closed for the creation of agricultural land and for protection against floods. Also there a combination of safety against flooding, need for agricultural land and availability of irrigation water was the driving force. Before 1975 these closure works were quite small. A few examples are:

| Site | Gap width (m) | channel depth (m) | execution time (manual labour) | tidal range (m) |

|---|---|---|---|---|

| Gangrail | 125 | 11 | ? | 3.0 |

| Koyra river | 90 | ?? | 90 | 3.0 |

| 245 | 8.5 | 80 | 2.5 |

Fundamentally the closures in Bangladesh were not different from elsewhere, but because of the low labour costs and the huge unemployment in the country, execution methods were selected including as much as possible local manpower.

These closure works were mainly done with some kind of locally developed fascine rolls, called mata. The final gap was closed as a sudden closure (within one tide). The Gangrail closure failed two times.

IN 1977/18 the Madargong creek was closed, protecting an agricultural area of 20,000 ha. The creek hat at the closure site a width of 150m and a bottom depth of 6 m below MSL. In 1978/79 the Chakamaya Khal was closed, a tidal prism of 10 million m3, tidal range 3.3 m and 210 m wide and 5 m deep.[7]: p731-743

In 1985 the Feni River in Bangladesh was closed to create a irrigation reservoir of 1200 ha.[6]: chapter 11 Here the client explicitly asked for a closure applying as much as possible local products and manual labour. The 1200 m wide closing gap had to be closed during one neap tide. On the day of the closure, 10,000 bags were placed in the closure gap by 12,000 workers.[6]: chapter 11

In 2020 the Nailan dam (originally constructed in the sixties of the 20th century) breached and had to be closed again. The basin size at that time was 480 ha, and a tidal range of 2.5 to 4 m (neap tide /spring tide). The gap width was 500 m and the tidal prism 7 million m3). This closure was effectuated by dumping a large number of geobags up to a weight of 250 kg. But most of the bags in the core of the closure were 50 kg. The gap was made smaller until a width of 75 m, which was the final closure gap. This gap was closed in one tidal cycle during neap tide. Two rows of palisades were placed in the gap, and during the closure the space between the palisades was filled with bags. In fact a cofferdam was formed[6]: chapter 15

Types of closures

We can divide the closing methods into two main groups, namely gradual closings and sudden closings. For gradual closures we can again distinguish four methods, namely horizontal closure without a significant sill (a), vertical closure (b), horizontal closure with sill (c) and sand closures. With sand closures, a distinction is also made between horizontal and vertical closures. The sudden closures are realized by using (sluice) caissons, usually placed on a sill (d).

The technology of closing works

The problem with closing a sea inlet is that if the flow area of the closing gap becomes smaller due to the construction of the dam, the flow speed increases. It then becomes so large that the material poured into the closing gap immediately washes away and the closure fails. Calculating the flow rate is therefore essential. Because the length of the basin is generally small compared to length of the tidal wave usually this can be done using a storage area approach (for details see at the end of this page). This makes it possible to create simple graphs of the velocities in a closure gap during the execution of a closure.

Stone closures

horizontal stone closures

Stone is put into the closing gap from both sides. The stone must be sufficiently heavy to withstand the increased speed due to the decreasing flow profile. An additional problem is that the narrowing of the closing gap creates turbulent eddies that cause additional scouring of the bottom. It is therefore necessary to protect the soil with a stone pour before the start of the closure. The attached photo of the closure of the Zuiderzee in 1932 clearly shows the turbulence downstream of the closing gap (by the way, when closing the Afsluitdijk, boulder clay was used, but this behaved exactly the same as stone and thus saved the expensive import of armourstone).

Horizontal stone closures have not been widely used in the Netherlands due to the costs of armourstone and the costs of soil protection. Abroad, where there is often much cheaper stone and less erosion-sensitive soil, horizontal stone closures are usually carried out. A very major work was the closure of the Saemangeum estuary in South Korea. There was also a shortage of very heavy stone, so they packed stone in steel nets and used it as dumping material.[8] Logistics are often the most complicated problem. Trucks with stone have to drive to the end of the (narrow) dam, dump the stone and drive back. Because the closure must be carried out in a short time (otherwise there is too much erosion of the bottom of the closure gap), many loads have to be unloaded in a short time. Turning at the head of the dam is difficult and often takes a lot of time.

vertical stone closures

From a hydraulic point of view, a vertical closure is therefore preferable. There is less turbulence and therefore there are far fewer problems with soil erosion. Implementation, on the other hand, is more difficult. For the part of the dam that remains well under water, sailing stone dumpers (bottom dumpers or side dumpers) can be used. But this is not possible for the last part of the dam because there is too little navigation depth. There are two options: an auxiliary bridge or a cable car.

auxiliary bridge

A temporary bridge can be built over the closing gap, after which armourstone can be poured from this dam into the closing gap. This option was considered for the Delta Works, for the Oesterdam closure, but sand closure turned out to be cheaper. In the Netherlands, this was done when the dike around the De Biesbosch polder was closed in 1926. A temporary bridge was built over the closing gap and the dam was closed by dumping material into the closing using tipping carts (pulled by a steam locomotive).

cable car

Building an auxiliary bridge is very cumbersome, especially for larger and deeper closing gaps. It was therefore decided to use a cable car to close a number of channels in the Delta Works. The first cable car connection was to the northern closing gap of the Grevelingendam. This was also done as a test to gain experience for the later larger closures of the Brouwershavense Gat and the Oosterschelde.

The transport of stone along the cables took place with wagons that had their own propulsion. The introduction of one-way traffic made high transport capacity possible. Due to the use of independently operating units, the susceptibility to malfunctions of the entire system was limited. The cable car was designed by Rijkswaterstaat together with the French company Neyrpic. The closing gap had a length of approximately 1200 m. The designed cable car was of the 'blondin automoteur continu' type. The track consisted of two carrying cables, to which fixed rail sections connected at both ends. These last sections of track ended in a turntable, along which the cars could pass from one track to the other. The wagons each had their own drive, consisting of a combustion engine, which also powered the hoisting device for the loads. The cars were manned. The carrying cables were attached to a fixed point on the northeast side; this anchor point has been preserved as a monument on the dam. On the other side they were attached to tilting counterweights. This ensured an almost constant tension in the cable. The payload was initially transported in four steel bottom unloading containers. These could be lifted and lowered together. Later, steel nets were also used. This allowed 360 tons of stone to be poured per hour.

However, it turned out that the loading capacity was insufficient, and also that unloading the stone took too much time. That is why concrete blocks of 1 m3 (2500 kg) were used for the following closures (Haringvliet and Brouwersdam). The intention was to also use this cable car for the closure of the Oosterschelde, but due to the policy change, this closure was not implemented, but a storm surge barrier was built instead.

Sand closure

In addition to closures with armourstone, a closure is also possible with sand alone. This requires a large capacity of dredgers. In the Netherlands, this has been done, among others, at the Oesterdam, the Philipsdam and during the construction of the Second Maasvlakte.[9]

Principle of the sand closure

With sand closures, dumping capacity is deployed in the closure gap such that more material is introduced per tide than can be carried away by the current. In contrast to closures with stone, material is used for the closure, which in itself is not stable in the occurring flow velocities. In general, sand closures do not require soil protection. Partly for this reason, a sand closure is financially attractive if locally extracted sand can be used. Since 1965, various tidal channels have been successfully closed with sand. The rapidly growing capacity of modern sand suction dredgers ensures that sand can be supplied quickly and in sufficient quantities at increasingly larger closures. Therefore, a fairly large loss of sand can be accepted in the closing phase, up to 20 to 50%. Partly based on the first sand closures of tidal channels - the Ventjagersgatje in 1959[10] and the closing gap in the southern entrance of the bridge over the Haringvliet in 1961 - a global calculation method for a sand closure could be developed. And on the basis of later sand closures, the calculation method developed at that time to predict sand losses was tested in practice.

Some sand closures

The table below provides an overview of a number of channels that have been closed with sand.[11][12][13]

| year | Surface (1000 m2) | Closing hole width (m) | area of closing hole (m2) | tidal range (m) | max. speed (m/s) | Closing duration (hours) | number of dredges | average sand production (1000 m3/hr) | max. sand production (1000 m3/hr) | sand loss (106 m3) | avg. erosion (1000 m3/hr) | grain size (mm) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Volkerak zuidelijk landhoofd | 1961 | n.v.t. | 1600 | 2,10 | 1,75 | 430 | 0,9 | ||||||

| Brielse Gat | 1966 | 800 | 1720 | 390 | 2,2 | 2,3 | 36 | 2 | 0,31 | 10,5 | 0,05 | 6 | 160 |

| Brielse Gat nevengeul | 1966 | 1570 | 1820 | 1120 | 2,2 | 2,9 | 63 | 2 | 1,14 | 20 | 0,43 | 12 | 160 |

| Oste (channel of Elbe) | 1968 | 300 | 1,5 | 1,5 | 3,3 | 90 | |||||||

| Zuidwal, Lauwerszee | 1968 | 3400 | 150 | ||||||||||

| Haringliet Zuid (Noord Pampus) | 1968 | 2430 | 1,3 | 37 | 2 | 0,22 | 135 | ||||||

| Brouwersdam | 1969 | 4200 | 66 | 3 | 0,25 | 200 | |||||||

| Eiderdam | 1972 | 3200+ 1200 | 1 | 160 | |||||||||

| Oosterschelde damvak geul | 1972 | n.v.t. | 2000 | 0,8 | 25 | 3 | 0,05 | 150 | |||||

| Meldorf Wöhrdenerloch | 1978 | 1700 | 1500 | 1150 | 3,2 | 2,5 | 10,5 | 6 | 350-90 | ||||

| Krammer | 1987 | n.v.t. | 1100 | 5580 | 2,24-0,5 | 2,2 | 6,5 | 14,7 | 22 | 7,1 | 200 | ||

| Tholense Gat | 1986 | n.v.t. | 355 | 1350 | 1,1 | 2,5 | 3 | 5,3 | 11 | 2,5 | 160 | ||

| Maasvlakte 2 (compartiment) | 2012 | 0,26 | 150 | 225 | 0,9 | 1 | 4,6 | 0,017 | 380 | ||||

| Maaasvlakte 2 | 2012 | 0,51 | 150 | 0,9 | 1 | 3 | 7,1 | 0,012 | 280 |

A number of compartments do not really have a closed basin, so the surface area there is not applicable.

At the closure of the Geul in the mouth of the Oosterschelde (tidal capacity approximately 30 million m3, maximum depth MSL -10 m) In the Oosterscheldedam between the working islands Noordland and Neeltje Jans in 1972, the sand losses could be limited by the use of large suction production. This amounted to more than 500,000 m3/week, divided over 3 suction dredgers. It has also clearly become apparent that closing from one side towards the shallowest part of the closing gap limits sand losses. With this method, the length of the sand dump is as short as possible towards the end of the closure, i.e. during the phase with the highest flow velocities, which partly explains the relatively high sand losses (approximately 45%) during the closure of the Brielse Gat (greatest depth MSL -2 m) where two sand dumps have been worked towards the middle. Working with one sand dump does have the disadvantage that large suction productions are needed and that the closing dam becomes very wide to accommodate all the discharge pipes.

Designing sand closures

Characteristic of a sand closure is the movement and loss of building material. A sand closure is based on the fact that more sand is produced than is lost. Depending on the flow conditions, sand loss occurs daily, even with an average flow through the closing gap. In terms of "strength and load", the "strength" of a sand closure is formed by the production capacity, and the "load" by the occurring loss. As long as production is greater than the loss, the closing gap becomes smaller and the closing is successful.[14]

The production capacity of the suction dredgers (including a sufficiently larger extraction location for the sand) must be greater than the maximum loss during the closure procedure. The investigation into whether a (complete) sand closure is possible will therefore first have to focus on the phase with maximum losses. Based on the hydraulic boundary conditions, the sand loss can be calculated for each phase of the closure and plotted in a graph as shown. The horizontal axis shows the size of the closing gap. In this figure, the selected capacity is therefore insufficient. It is therefore not possible to carry out a sand closure with this capacity.

If sufficient sand production can be achieved in the vicinity of the closure gap to get through this phase, sand closure is possible. The criterion should be that the tidal average loss must remain smaller than the production. Attention must be paid to the large uncertainties in both the calculated losses and the predicted production. The losses as a function of the closing hole area are described by a curve with one maximum. The maximum sought will almost always correspond to a value of the closing gap area that lies between 0 and 30% of the original value of the closing hole area. Initially, the calculations of sand losses can therefore be limited to this closing gap size.

The maximum sand loss does not occur when the closing gap is almost closed. The flow velocities may be high, but the width of the closure hole that is being eroded is so small that the total sand losses are still small. The hydraulic boundary conditions can be calculated with a storage/area approach.

In general it can be stated that a sand closure is in principle feasible up to maximum flow velocities of about 2.0 to 2.5 m/s. At higher flow velocities, a sand closure will be virtually impossible. The occurring flow rates are determined by the reference flow rate U0 and the discharge coefficient μ. The magnitude of the discharge coefficient μ is determined by both the friction losses and the deceleration losses in the closing gap. Given the large size of the sand dams in the closing gap, friction losses play a relatively large role. The discharge coefficient is therefore strongly influenced by the choice of the distance over which the gradient is determined. The values of the discharge coefficient found also show a relatively large spread. In the final, decisive phase of the closure, the spread in the discharge coefficient decreases. For this phase it is recommended to use 0.9 as a reasonable upper limit.[15] The actual flow velocity in the closing gap is the velocity calculated with the storage area approach, multiplied by the discharge coefficient.

Sudden closures (caissons)

A sudden closure is a closure of a tidal inlet or dike breach by preparing the closing gap in such a way that this closing gap can be closed in one go during slack tide. Usually caissons or sluice caissons are used for this, but there are also some special closures that use sandbags or ships. Caissons were used for first time as an emergency measure to close dike breaches after the Allied Battle of Walcheren in 1944, and then after the storm disaster of 1953. This technology has been further developed for the Delta Works.

Caisson closure

With a caisson closure, the closing gap is closed by entering a caisson, a large concrete box. This was done for the first time in the Netherlands when closing the dike breaches caused by the Allied attacks during Operation Infatuate on Walcheren in 1944. When closing the dikes in 1945 at Rammekens, surplus caissons (Phoenix caissons) available in England such as those after the landing in Normandy, the Allied troops were used to create makeshift harbours, the so-called Mulberry harbours.

After the storm disaster of 1953, many breaches had to be closed, and the idea was that many of them could be closed with a caisson. But because the size of the final closing gaps was not known and the construction of the caissons takes quite some time, it was decided shortly after February 1, 1953 to have a large number of relatively small caissons made in advance, which were used in many places. could become the unit caissons. These caissons were later also used in the Delta Works.[16]

Phoenix caissons from the Mulberryhavens were also used for a small number of larger dike breaches, but the available number was very small. These large caissons were used at Ouwerkerk and Schelphoek, among others.

Placing a caisson

[[File:AfzinkenEN.png|thumb|time needed for sinking[7]Cite error: A <ref> tag is missing the closing </ref> (see the help page).[17] Sluice caissons have also been used in the Lauwerszee.[18]

Design of sluice caissons

With caisson closures it is necessary to maintain the largest possible effective flow profile during installation. In addition, the discharge coefficient must be as large as possible. This is the extent to which the flow is hindered by the shape of the caisson.

Flow area

The flow area of an individual caisson should be as large as possible. This can be achieved by:

- As large a distance as possible between the caisson walls. Sufficient torsional stiffness can be obtained with steel diagonals.

- The bottom of the caissons should be as thin as possible.

- To obtain sufficient weight of the caisson, ballast spaces can be designed in the superstructure of the caisson. This extra weight is necessary to mobilize sufficient friction between the caisson and the threshold.

Discharge coefficient

In addition to the flow area, the discharge coefficient is of great importance. Discharge coefficient improving measures are:

- Streamlining the diagonals between the walls.

- Applying additional deposits to streamline the threshold.

The accompanying table shows the discharge coefficients of some caissons designed in the Netherlands.

| Sill depth under MSL | discharge coefficient | |

|---|---|---|

| Veerse Gat 1961 | -5,5 m | 0,78 |

| Lauwerszee 1969 | -6,5 m | 0,65 |

| Volkerak 1969 | -7 m | 0,75 |

| Brouwersdam 1971 | -10 m | 0,85 |

| Oosterschelde (design) | -20 m | 1,00 |

Special closures

closure by sinking ships

[[File:Memorial_Watersnoodramp_1953_Hollandse_IJssel_01.jpg|thumb|Monument "a dime on its side" near Nieuwerkerk aan den IJssel]] In special cases, usually in emergencies such as dike breaches, an attempt is made to close the breach by entering a ship into the breach. This usually goes wrong because the dimensions of the ship do not match the dimensions of the closing hole. It has also often happened that the ship sails into the breach and is then pushed in or out by the strong current. Finally, one reason that things often go wrong is because the bottom of the ship does not fit properly with the bottom of the closing gap, causing underwatering. The strong current then causes further erosion under the ship, which means that no closure is achieved. One of the few cases where this went well was in 1953 during a dike breach along the Hollandse IJssel. A monument was later placed at this location.[20]

In Korea, a tidal inlet was closed in 1980 using the sinking of an old oil tanker. Little is known about the implementation of this closure, which usually means that it was not very successful, especially since many dozens of closures were carried out in Korea after that date, but these were always stone closures. Google Earth recordings from a later date reveal that the ship was removed again after the dam closed.

closure with sandbags

A special form of closure is by using sandbags and a very large number of workers. This was done, among other things, during the construction of the dam in the Feni river in Bangladesh. Here the bottom of the tidal inlet was virtually dry during low tide. 12 depots with sandbags of 100,000 bags each were placed in the 1200 m wide closing gap. On the day of the closure, these bags were placed in the closure gap by 12,000 workers. This happened in six hours, with the placing of the bags slightly faster than the rise of the water. At the end of that day the tidal inlet was closed, although only for the water levels that occur during neap tide. But in the following days, this dam could be further raised with sand, so that it could also withstand spring tide (spring tide dam) and in the following three months also against storm surges (of 10 m above the bottom of the dam).[21][22]

storage area approach

Using tidal prism for velocity calculation in the neck of an tidal inlet

If a tidal basin is not too large (i.e. its length is small compared to the length of the tidal wave [23]) one can assume that the water level in this basin remains horizontal and only rises and falls with the tide. In that case, the basin storage (tidal prism) is equal to the surface area of the basin multiplied by the tidal difference in the basin.

In its simplest form, the following applies to the basin storage:

in which:

- = tidal prism (m3)

- = area of the basin (m2)

- = tidal range at the mouth (m)

This simple approach makes it possible to make a good estimate of the current velocities in the tidal inlet, which is necessary if this basin has to be closed. As stated, the storage area approach is a very simple method to determine local hydraulic boundary conditions for a barrier structure.

In the storage area approach, the water movement in the estuary is schematized without the influence of friction and inertia. The storage area equation is as follows:

Here Q is the flow rate in the tidal inlet, B is the surface area of the basin storage and is the rising or falling speed of the water in the basin.

The figure shows a basin storage system. This basin storage system has the following preconditions:

- a river discharge, which is imposed as a flow rate as a function of time , where inflow is assumed positive.

- a flow through the closing gap , which is completely determined by the difference between upstream energy height and water level in the closing gap and and the drainage properties of the closing gap, such as width, sill height and discharge coefficient.

For an imperfect weir situation, the following applies:

For a perfect weir situation:

In the above formulas the symbols have the following meaning

| Qs | flow rate through the closing gap [m3/s] |

| Wg | flow area at the closing gap [m2] |

| g | acceleration of gravity [m/s2] |

| H1 | energy height upstream of the closing gap compared to the sill level [m] |

| h2 | water level in the closing gap compared to the sill level [m] |

| h3 | water level downstream of the closing gap compared to the sill level [m] |

| d | sill height of the closing gap [m] |

| μ | discharge coefficient for the imperfect weir situation [-] |

| m | discharge coefficient for the perfect weir situation [-]. |

By combining the above equations, the basin storage equation for the system is obtained. This gives:

This makes it possible to create simple graphs of the velocities in a closure hole during the creation of a closure. In the attached example for a tidal amplitude of 2.5 m (i.e. a tidal difference of 5 m), the speed is indicated as a function of the ratio of tidal storage area (B) over the closing gap width (Wg) and the depth of the sill (d'). The red line indicates a so-called vertical closure, whereby the hole is deepened over the entire width of the closure hole during the closure (this happens, for example, with a closure with a cable car). The orange line indicates a horizontal closure, where the hole is closed from both sides. This graph shows that the maximum speeds that occur during a horizontal closure are much greater than with a vertical closure. The green line indicates a combination; first a part is closed horizontally and then the remainder vertically.

General reference

- Huis in 't Veld, Hans (1987). The closure of tidal basins: Closing of estuaries: tidal inlets and dike breaches. Delft: Delft University press. ISBN 90-6275-287-X.

{{cite book}}: CS1 maint: date and year (link) - Konter, J.L.M.; Klatter, H.E.; Jorissen, R.E. (1992). Afsluitdammen, regels voor het ontwerp [Closure dams, rules for design] (in Dutch). Rijkswaterstaat, Bouwdienst.

- Van Roode, Ferd (1994). Damming of tidal estuaries and lowland rivers. Delft: Delft University of Technology.

- Verhagen, Henk Jan (2017). Closure works. Delft: Delft Academic press. ISBN 9789065624024.

References

- ^ Stamhuis, Eisen (1998). Afsluitingstechnieken in de Nederlandse Delta: Een overzicht van de ontwikkeling van deze techniek [Closure techniques in the Dutch Delta] (in Dutch). Ministerie van Verkeer en Waterstaat. pp. 21–28.

- ^ L.G., Van Breen (1920). Holland’s Rijshout [Fascines from the Netherlands] (in Dutch). Oosterbaan en le Contre, Goes. pp. 172–179.

- ^ Verhagen (2017) p33

- ^ Tarnow, Robert; Petersen, Peter; Petersen, Karl (1978). Speicherkoog Dithmarschen, eind neuer Deich verändert die Landschaft. Meldorf: Evers Velag.

- ^ Yoon, Oh Seup (2003). Historical developments of reclamation works in Korea, Workshop on Hydro-environmental Impacts from Large Coastal Developments. Seoul: Korean Society of coastal and ocean engineers.

- ^ a b c d van Duivendijk, Hans (2024). Restoring dike breaches and closing tidal channels by simple means from past to present (Ph.D.-thesis ed.). TU Delft.

- ^ a b Huis in 't Veld (1987)

- ^ Nedeco (1989). Saemankeum Comprehensive Tideland Reclamation Project: Feasibility Study on Hydraulic Filling of Seadikes. Korean Research Institute for Reclamation (KRIR).

- ^ Struik, Peter (1993). Sand Closures. CUR Gouda (CRC Press). ISBN 9789054101437.

- ^ "De Volkerakwerken" [Volkerak works]. Driemaandelijks bericht Deltawerken (in Dutch) (6): 23 (pdf 283). 1958.

- ^ Huis in 't Veld, M.J.H. (2015-02-26). Sand closure Bintan Bay. TU Delft hydraulic engineering, MSc thesis.

- ^ Willems, J.A. (2013-11-14). Investigation of the sand losses which occur during construction of a closure dam in a tidal inlet. TU Delft, Hydraulic engineering, MSc thesis.

- ^ Struik (1993) pages 23-34; appendix A, B

- ^ d'Angremond, Kees (2008). Breakwaters and Closure Dams. Delft Academic Press - VSSD. p. 179-185. ISBN 978-90-6562-173-3.

- ^ Konter et.al (1992) page 35

- ^ Rijkswaterstaat (1961). Verslag over de stormvloed [Report on the storm surge"] (in Dutch). Staatsuitgeverij. pp. 385–395.

- ^ "De afsluiting van het Volkerak" [The closure of the Volkerak]. Driemaandelijk Bericht Deltawerken (in Dutch) (38): 419. 1966.

- ^ "Het sluitgat van de afsluitdijk voor de Lauwerszee" [The closure gap of the closuredam of the Lauwerszee]. Driemaandelijks bericht Deltawerken (in Dutch). 4e tiental (37): 377. 1966.

- ^ Konter et al (1992)page 61

- ^ "Zuid-Holland ontsnapte ternauwernood aan Watersnood in 1953" [Southern Holland just escaped from flooding in 1953] (in Dutch).

- ^ Van Duivendijk, Hans (1983). Feni closure dam, final design report. Nijmegen: Royal Haskoning.

- ^ te Slaa, G. (1985). Report on the construction of the Feni river closure dam. Nijmegen: Royal Haskoning.

- ^ The length of a tidal wave depends on the speed of that wave, which in turn depends on the water depth (d). For a depth of approximately 10 m, the walking speed is c= = 10 m/s). The wavelength is then cT, where T is the period of the tidal wave (approximately 12.5 hours). The wavelength at this depth is therefore approximately 450 km. A basin of about 20 km is therefore only 5% of the tidal wavelength, and is therefore short.