Contact mechanics: Difference between revisions

Ref in English for Hertz's paper |

|||

| Line 3: | Line 3: | ||

'''Contact mechanics''' is the study of the [[Deformation (mechanics)|deformation]] of [[solids]] that touch each other at one or more points<ref name=Johnson>Johnson, K. L, 1985, '''Contact mechanics''', Cambridge University Press.</ref><ref name=Popov>Popov, Valentin L., 2010, ''Contact Mechanics and Friction. Physical Principles and Applications'', Springer-Verlag, 362 p., ISBN 978-3-642-10802-0.</ref>. The physical and mathematical formulation of the subject is built upon the [[mechanics of materials]] and [[continuum mechanics]] and focuses on computations involving [[Elasticity (physics)|elastic]], [[viscoelasticity|viscoelastic]], and [[Plastic Deformation|plastic]] bodies in [[Statics|static]] or [[Dynamics (physics)|dynamic]] contact. Contact mechanics is foundational to the field of mechanical [[engineering]]; it provides necessary information for the safe and energy efficient design of technical systems. |

'''Contact mechanics''' is the study of the [[Deformation (mechanics)|deformation]] of [[solids]] that touch each other at one or more points<ref name=Johnson>Johnson, K. L, 1985, '''Contact mechanics''', Cambridge University Press.</ref><ref name=Popov>Popov, Valentin L., 2010, ''Contact Mechanics and Friction. Physical Principles and Applications'', Springer-Verlag, 362 p., ISBN 978-3-642-10802-0.</ref>. The physical and mathematical formulation of the subject is built upon the [[mechanics of materials]] and [[continuum mechanics]] and focuses on computations involving [[Elasticity (physics)|elastic]], [[viscoelasticity|viscoelastic]], and [[Plastic Deformation|plastic]] bodies in [[Statics|static]] or [[Dynamics (physics)|dynamic]] contact. Contact mechanics is foundational to the field of mechanical [[engineering]]; it provides necessary information for the safe and energy efficient design of technical systems. |

||

The original work in contact mechanics dates back to [[1882]] with the publication of the paper "On the contact of elastic solids" ([http://gdz.sub.uni-goettingen.de/no_cache/dms/load/img/?IDDOC=251917 "Ueber die Berührung fester elastischer Körper"]) by [[Heinrich Hertz]]. Hertz was attempting to understand how the optical properties of multiple, stacked [[lens (optics)|lenses]] might change with the [[force]] holding them together. Results in this field have since been extended to all branches of engineering, but are most essential in the study of [[tribology]] and [[indentation hardness]]. Hertzian contact stress refers to the localized stresses that develop as two curved surfaces come in contact and deform slightly under the imposed loads. This amount of deformation is dependent on the [[modulus of elasticity]] of the material in contact. It gives the contact stress as a function of the normal contact force, the radii of curvature of both bodies and the modulus of elasticity of both bodies. In gears and bearings in operation, these contact stresses are cyclic in nature and over time lead to sub-surface fatigue cracks. Hertzian contact stress forms the foundation for the equations for load bearing capabilities in bearings, gears, and any other bodies where two surfaces are in contact. |

The original work in contact mechanics dates back to [[1882]] with the publication of the paper "On the contact of elastic solids"<ref> H. Hertz, Über die berührung fester elastischer Körper (On the contact of rigid elastic solids). In: ''[http://www.archive.org/details/cu31924012500306 Miscellaneous Papers]''. Jones and Schott, Editors, ''J. reine und angewandte Mathematik'' 92, Macmillan, London (1896), p. 156 English translation: Hertz, H.</ref> ([http://gdz.sub.uni-goettingen.de/no_cache/dms/load/img/?IDDOC=251917 "Ueber die Berührung fester elastischer Körper"]) by [[Heinrich Hertz]]. Hertz was attempting to understand how the optical properties of multiple, stacked [[lens (optics)|lenses]] might change with the [[force]] holding them together. Results in this field have since been extended to all branches of engineering, but are most essential in the study of [[tribology]] and [[indentation hardness]]. Hertzian contact stress refers to the localized stresses that develop as two curved surfaces come in contact and deform slightly under the imposed loads. This amount of deformation is dependent on the [[modulus of elasticity]] of the material in contact. It gives the contact stress as a function of the normal contact force, the radii of curvature of both bodies and the modulus of elasticity of both bodies. In gears and bearings in operation, these contact stresses are cyclic in nature and over time lead to sub-surface fatigue cracks. Hertzian contact stress forms the foundation for the equations for load bearing capabilities in bearings, gears, and any other bodies where two surfaces are in contact. |

||

Principles of contacts mechanics can be applied in areas such as locomotive wheel-rail contact, [[coupling]] devices, [[Brake|braking]] systems, [[tire]]s, [[bearing (mechanical)|bearings]], [[Internal combustion engine|combustion engines]], mechanical [[linkage]]s, [[gasket]] seals, [[metalworking]], metal forming, [[ultrasonic welding]], [[Electrical connector|electrical contacts]], and many others. Current challenges faced in the field may include [[stress analysis]] of contact and coupling members and the influence of [[lubrication]] and material [[design]] on [[friction]] and [[wear]]. Applications of contact mechanics further extend into the [[Microtechnology|micro]]- and [[Nanotechnology|nanotechnological]] realm. |

Principles of contacts mechanics can be applied in areas such as locomotive wheel-rail contact, [[coupling]] devices, [[Brake|braking]] systems, [[tire]]s, [[bearing (mechanical)|bearings]], [[Internal combustion engine|combustion engines]], mechanical [[linkage]]s, [[gasket]] seals, [[metalworking]], metal forming, [[ultrasonic welding]], [[Electrical connector|electrical contacts]], and many others. Current challenges faced in the field may include [[stress analysis]] of contact and coupling members and the influence of [[lubrication]] and material [[design]] on [[friction]] and [[wear]]. Applications of contact mechanics further extend into the [[Microtechnology|micro]]- and [[Nanotechnology|nanotechnological]] realm. |

||

Revision as of 08:31, 27 April 2010

| Part of a series on |

| Continuum mechanics |

|---|

Contact mechanics is the study of the deformation of solids that touch each other at one or more points[1][2]. The physical and mathematical formulation of the subject is built upon the mechanics of materials and continuum mechanics and focuses on computations involving elastic, viscoelastic, and plastic bodies in static or dynamic contact. Contact mechanics is foundational to the field of mechanical engineering; it provides necessary information for the safe and energy efficient design of technical systems.

The original work in contact mechanics dates back to 1882 with the publication of the paper "On the contact of elastic solids"[3] ("Ueber die Berührung fester elastischer Körper") by Heinrich Hertz. Hertz was attempting to understand how the optical properties of multiple, stacked lenses might change with the force holding them together. Results in this field have since been extended to all branches of engineering, but are most essential in the study of tribology and indentation hardness. Hertzian contact stress refers to the localized stresses that develop as two curved surfaces come in contact and deform slightly under the imposed loads. This amount of deformation is dependent on the modulus of elasticity of the material in contact. It gives the contact stress as a function of the normal contact force, the radii of curvature of both bodies and the modulus of elasticity of both bodies. In gears and bearings in operation, these contact stresses are cyclic in nature and over time lead to sub-surface fatigue cracks. Hertzian contact stress forms the foundation for the equations for load bearing capabilities in bearings, gears, and any other bodies where two surfaces are in contact.

Principles of contacts mechanics can be applied in areas such as locomotive wheel-rail contact, coupling devices, braking systems, tires, bearings, combustion engines, mechanical linkages, gasket seals, metalworking, metal forming, ultrasonic welding, electrical contacts, and many others. Current challenges faced in the field may include stress analysis of contact and coupling members and the influence of lubrication and material design on friction and wear. Applications of contact mechanics further extend into the micro- and nanotechnological realm.

The motion of a single body in space is described by the governing equations of continuum mechanics. The approach used in contact mechanics is to restrict the the motion of two or more bodies in space by additional constraints. These unilateral constraints ensure that bodies do not penetrate each other after coming into contact. Once the general equations for a contact problem are set up, different solution schemes can be used to simulate the behaviour of bodies in contact and to compute displacement and stress fields. A distinction is usually drawn between contact with and without friction.

History

Classical contact mechanics is most notably associated with Heinrich Hertz[4]. In 1882 Hertz solved the problem involving contact between two elastic bodies with curved surfaces. This still-relevant classical solution provides a foundation for modern problems in contact mechanics. For example, in mechanical engineering and tribology, Hertzian contact stress, is a description of the stress within mating parts. In general, the Hertzian contact stress is usually refers to the stress close to the area of contact between two spheres of different radii.

It was not until nearly one hundred years later that Johnson, Kendall, and Roberts found a similar solution for the case of adhesive contact [5]. This theory was rejected by Boris Derjaguin and co-workers[6] who proposed a different theory of adhesion[7] in the 1970's. The Derjaguin model came to be known as the DMT (after Derjaguin, Muller and Toporov) model[7], and the Johnson et al. model came to be known as the JKR (after Johnson, Kendall and Roberts) model for adhesive elastic contact. This rejection proved to be instrumental in the development of the Tabor[8] and later Maugis[6] [9]parameters that quantify which contact model (of the JKR and DMT models) represent adhesive contact better for specific materials.

Further advancement in the field of contact mechanics in the mid-twentieth century may be attributed to names such as Bowden and Tabor. Bowden and Tabor were the first to emphasize the importance of surface roughness for bodies in contact[10][11]. Through investigation of the surface roughness, the true contact area between friction partners is found to be less than the apparent contact area. Such understanding also drastically changed the direction of undertakings in tribology. The works of Bowden and Tabor yielded several theories in contact mechanics of rough surfaces.

The contributions of Archard (1957)[12] must also be mentioned in discussion of pioneering works in this field. Archard concluded that, even for rough elastic surfaces, the contact area is approximately proportional to the normal force. Further important insights along these lines were provided by Greenwood and Williamson (1966)[13], Bush (1975)[14], and Persson (2002)[15]. The main findings of these works were that the true contact surface in rough materials is generally proportional to the normal force, while the parameters of individual micro-contacts (i.e. pressure, size of the micro-contact) are only weakly dependent upon the load.

Non-adhesive contact

The classical theory of contact focused primarily on non-adhesive contact where no tension force is allowed to occur within the contact area, i.e, contacting bodies can be separated without adhesion forces. Several analytical and numerical approaches have been used to solve contact problems that satisfy the no-adhesion condition. Complex forces and moments are transmitted between the bodies where they touch, so problems in contact mechanics can become quite sophisticated. In addition, the contact stresses are usually a nonlinear function of the deformation. To simply the solution procedure, a frame of reference is usually defined in which the objects (possibly in motion relative to one another) are static. They interact through surface tractions (or pressures/stresses) at their interface.

As an example, consider two objects which meet at some surface in the (,)-plane with the -axis assumed normal to the surface. One of the bodies will experience a normally-directed pressure distribution and in-plane surface traction distributions and over the region . In terms of a Newtonian force balance, the forces:

must be equal and opposite to the forces established in the other body. The moments corresponding to these forces:

are also required to cancel between bodies so that they are kinematically immobile.

The following assumptions are made in determining the solutions of Hertzian contact problems:

- the strains are small and within the elastic limit,

- each body can be considered an elastic half-space, i.e,, the area of contact is much smaller than the chracteriztic radius of the body,

- the surfaces are continuous and non-conforming, and

- the surfaces are frictionless.

Additional complications arise when some or all these assumptions are violated and such contact problems are usually called non-Hertzian.

Analytical solution techniques

Analytical solution methods for non-adhesive contact problem can be classified into two types based on the geometry of the area of contact[16]. A conforming contact is one in which the two bodies touch at multiple points before any deformation takes place (i.e., they just "fit together"). A non-conforming contact is one in which the shapes of the bodies are dissimilar enough that, under zero load, they only touch at a point (or possibly along a line). In the non-conforming case, the contact area is small compared to the sizes of the objects and the stresses are highly concentrated in this area.

A common approach in linear elasticity is to superpose a number of solutions each of which corresponds to a point load acting over the area of contact. For example, in the case of loading of a half-plane, the Flamant solution is often used as a starting point and then then generalized to various shapes of the area of contact. The force and moment balances between the two bodies in contact act as additional constraints to the solution.

Numerical solution techniques

Distinctions between conforming and non-conforming contact do not have to be made when numerical solution schemes are employed to solve contact problems. These methods do not rely on further assumptions within the solution process since they base solely on the general formulation of the underlying equations[17] [18] [19] [20]. Besides the standard equations describing the deformation and motion of bodies two additional inequalities can be formulated. The first simply restricts the motion and deformation of the bodies by the assumption that no penetration can occur. Hence the gap between two bodies can only be positive or zero

where denotes contact. The second assumption in contact mechanics is related to the fact, that no tension force is allowed to occur within the contact area (contacting bodies can be lifted up without adhesion forces). This leads to an inequality which the stresses have to obey at the contact interface. It is formulated for the contact pressure

Since for contact, , the contact pressure is always negative, , and further for non contact the gap is open, , and the contact pressure is zero, , the so called Kuhn-Tucker form of the contact constraints can be written as

These conditions are valid in a general way. The mathematical formulation of the gap depends upon the kinematics of the underlying theory of the solid (e.g., linear or nonlinear solid in two- or three dimensions, beam or shell model).

Classical solutions

Point contact on a half-plane

A starting point for solving contact problems is to understand the effect of a "point-load" applied to an isotropic, homogeneous, and linear elastic half-plane, shown in the figure to the right. The problem may be either be plane stress or plane strain. This is a boundary value problem of linear elasticity subject to the traction boundary conditions:

where is the Dirac delta function. The boundary conditions state that are no shear stresses on the surface and a singular normal force P is applied at (0,0)). Applying these conditions to the governing equations of elasticity produces the result

for some point, , in the half-plane. The circle shown in the figure indicates a surface on which the maximum shear stress is constant. From this stress field, the strain components and thence displacements of all material points may be determined.

Line contact on a half-plane

Normal loading over a region

Suppose, rather than a point load , a distributed load is applied to the surface instead, over the range . The principle of linear superposition can be applied to determine the resulting stress field as the solution to the integral equations:

Shear loading over a region

The same principle applies for loading on the surface in the plane of the surface. These kinds of tractions would tend to arise as a result of friction. The solution is similar the above (for both singular loads and distributed loads ) but altered slightly:

These results may themselves be superposed onto those given above for normal loading to deal with more complex loads.

Contact between a Sphere and an Elastic Half-Space

An elastic sphere of radius indents an elastic half-space to depth , and thus creates a contact area of radius . The applied force is related to the displacement by

where

and , are the elastic moduli and , the Poisson's ratios associated with each body.

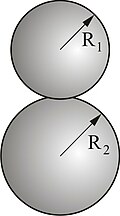

Contact between two spheres

For contact between two spheres of radii and , the area of contact is a circle of radius . The distribution of normal traction in the contact area as a function of distance from the center of the circle is[1]

where is the maximum contact pressure given by

where the effective radius is defined as

The area of contact is related to the applied load by the equation

The depth of indentation is related to the maximum contact pressure by

The maximum shear stress occurs in the interior at for .

Contact between Two Crossed Cylinders of Equal Radius

This is equivalent to contact between a sphere of radius and a plane (see above).

Contact between a Rigid Cylinder and an Elastic Half-Space

If a rigid cylinder is pressed into an elastic half-space, it creates a pressure distribution described by[21]

where is the radius of the cylinder and

The relationship between the indentation depth and the normal force is given by

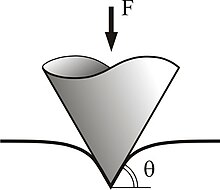

Contact between a Rigid Conical Indenter and an Elastic Half-Space

In the case of indentation of an elastic half-space using a rigid conical indenter, the indentation depth and contact radius are related by[21]

with defined as the angle between the plane and the side surface of the cone. The pressure distribution takes on the form

The stress has a logarithmic singularity on the tip of the cone. The total force is

Contact between Two Cylinders with Parallel Axes

In contact between two cylinders with parallel axes, the force is linearly proportional to the indentation depth:

The radii of curvature are entirely absent from this relationship. The contact radius is described through the usual relationship

with

as in contact between two spheres. The maximum pressure is equal to

Contact between Rough Surfaces

When two bodies with rough surfaces are pressed into each other, the true contact area is much smaller than the apparent contact area . In contact between a "random rough" surface and an elastic half-space, the true contact area is related to the normal force by[22]

with equal to the root mean square (also known as the quadratic mean) of the surface slope and . The median pressure in the true contact surface

can be reasonably estimated as half of the effective elastic modulus multiplied with the root mean square of the surface slope .

Given that the pressure is greater than the material yield stress , it follows that

represents the micro-roughnesses in a state of complete plasticity. For , the surface behaves elastically during contact. The parameter was introduced by Greenwoord and Williamson and is referred to as the plasticity index. Whether the system behaves plastically or elastically is independent of the applied normal force.

Adhesive contact

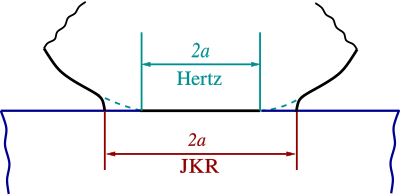

When two solid surfaces are brought into close proximity to each other they experience attractive van der Waals forces. Bradley's van der Waals model[23] provides a means of calculating the tensile force between two rigid spheres with perfectly smooth surfaces. The Hertzian model of contact does not consider adhesion possible. However, in the late 1960s, several contradictions were observed when the Hertz theory was compared with experiments involving contact between rubber and glass spheres.

It was observed[5] that, though Hertz theory applied at large loads, at low loads

- the area of contact was larger than that predicted by Hertz theory,

- the area of contact had a non-zero value even when the load was removed, and

- there was strong adhesion if the contacting surfaces were clean and dry.

This indicated that adhesive forces were at work. The Johnson-Kendall-Roberts (JKR) model and the Derjaguin-Muller-Toporov (DMT) models were the first to incorporate adhesion into Hertzian contact.

Bradley model for rigid contact

It is commonly assumed that the surface force between two atomic planes at a distance from each other can be derived from the Lennard-Jones potential. With that assumption we can write

where is the force (positive in compression), is the is the total surface energy of both surfaces per unit area, and is the equilibrium separation of the two atomic planes.

The Bradley model assumed applied the Lennard-Jones potential to find the force of adhesion between two rigid spheres. The total force between the spheres is found to be

where are the radii of the two spheres.

The two spheres separate completely when the pull-off force is achieved at at which point

Johnson-Kendall-Roberts (JKR) model for elastic contact

To incorporate the effect of adhesion in Hertzian contact, Johnson, Kendall, and Roberts[5] formulated the JKR theory of adhesive contact using a balance between the stored elastic energy and the loss in surface energy. The JKR model considers the effect of contact pressure and adhesion only inside the area of contact. The general solution for the pressure distribution in the contact area in the JKR model is

Note that in the original Hertz theory, the term containing was neglected on the ground that tension could not be sustained in the contact zone. For contact between two spheres

where is the radius of the area of contact, is the applied force, is the total surface energy of both surfaces per unit contact area, are the radii, Young's moduli, and Poisson's ratios of the two spheres, and

The approach distance between the two spheres is given by

The Hertz equation for the area of contact between two spheres, modified to take into account the surface energy, has the form

When the surface energy is zero, , the Hertz equation for contact between two spheres is recovered. When the applied load is zero, the contact radius is

The tensile load at which the spheres are separated, i.e., , is predicted to be

This force is also called the pull-off force. Note that this force is independent of the moduli of the two spheres. However, there is another possible solution for the value of at this load. This is the critical contact area , given by

If we define the work of adhesion as

where are the adhesive energies of the two surfaces and is an interaction term, we can write the JKR contact radius as

The tensile load at separation is

and the critical contact radius is given by

The critical depth of penetration is

Derjaguin-Muller-Toporov (DMT) model for elastic contact

The Derjaguin-Muller-Toporov model[24][25] developed an alternative model for adhesive contact. The DMT theory assumed that the contact profile remained the same as in Hertzian contact but will additional attractive interactions outside the area of contact.

The Hertz equation for the area of contact between two spheres from DMT theory is

and the pull-off force is

When the pull-off force is achieved the contact area becomes zero and there is no singularity in the contact stresses at the edge of the contact area.

In terms of the work of adhesion

and

Tabor coefficient

In 1977, Tabor[26] showed that the apparent contradiction between the JKR and DMT theories could be resolved by noting that the two theories were the extreme limits of a single theory parametrized by the Tabor coefficient () defined as

where is the equilibrium separation between the two surfaces in contact. The JKR theory applies to large, compliant spheres for which is large. The DMT theory applies for small, stiff spheres with small values of .

Maugis-Dugdale model for elastic contact

Further improvement to the Tabor idea was provided by Maugis[9] who represented the surface force in terms of a Dugdale cohesive zone approximation such that the work of adhesion is given by

where is the maximum force predicted by the Lennard-Jones potential and is the maximum separation obtained by matching the areas under the Dugdale and Lennard-Jones curves (see adjacent figure). This means that the attractive force is constant for . There is not further penetration in compression. Perfect contact occurs in an area of radius and adhesive forces of magnitude extend to an area of radius . In the region , the two surfaces are separated by a distance with and . The ratio is defined as

- .

In the Maugis-Dugdale theory[27], the surface traction distribution is divided into two parts - one due to the Hertz contact pressure and the other from the Dugdale adhesive stress. Hertz contact is assumed in the region . The contribution to the surface traction from the Hertz pressure is given by

where the Hertz contact force is given by

The penetration due to elastic compression is

The vertical displacement at is

and the separation between the two surfaces at is

The surface traction distribution due to the adhesive Dugdale stress is

The total adhesive force is then given by

The compression due to Dugdale adhesion is

and the gap at is

The net traction on the contact area is then given by and the net contact force is . When the adhesive traction drops to zero.

Non-dimensionalized values of are introduced at this stage that are defied as

In addition, Maugis proposed a parameter which is equivalent to the Tabor coefficient. This parameter is defined as

Then the net contact force may be expressed as

and the elastic compression as

The equation for the cohesive gap between the two bodies takes the form

This equation can be solved to obtain values of for various values of and . For large values of , and the JKR model is obtained. For small values of the DMT model is retrieved.

Carpick-Ogletree-Salmeron (COS) model

The Maugis-Dugdale model can only be solved iteratively if the value of is not known a-priori. The Carpick-Ogletree-Salmeron approximate solution [28] simplifies the process by using the following relation to determine the contact radius :

where is the contact area at zero load, and is a transition parameter that is related to by

The case corresponds exactly to JKR theory while corresponds to DMT theory. For intermediate cases the COS model corresponds closely to the Maugis-Dugdale solution for .

References

- ^ a b Johnson, K. L, 1985, Contact mechanics, Cambridge University Press.

- ^ Popov, Valentin L., 2010, Contact Mechanics and Friction. Physical Principles and Applications, Springer-Verlag, 362 p., ISBN 978-3-642-10802-0.

- ^ H. Hertz, Über die berührung fester elastischer Körper (On the contact of rigid elastic solids). In: Miscellaneous Papers. Jones and Schott, Editors, J. reine und angewandte Mathematik 92, Macmillan, London (1896), p. 156 English translation: Hertz, H.

- ^ Hertz, H. R., 1882, Ueber die Beruehrung elastischer Koerper (On Contact Between Elastic Bodies), in Gesammelte Werke (Collected Works), Vol. 1, Leipzig, Germany, 1895.

- ^ a b c K. L. Johnson and K. Kendall and A. D. Roberts, Surface energy and the contact of elastic solids, Proc. R. Soc. London A 324 (1971) 301-313

- ^ a b D. Maugis, Contact, Adhesion and Rupture of Elastic Solids, Springer-Verlag, Solid-State Sciences, Berlin 2000, ISBN 3-540-66113-1

- ^ a b B. V. Derjaguin and V. M. Muller and Y. P. Toporov, Effect of contact deformations on the adhesion of particles, J. Colloid Interface Sci. 53 (1975) 314--325

- ^ D. Tabor, The hardness of solids, J. Colloid Interface Sci. 58 (1977) 145-179

- ^ a b D. Maugis, Adhesion of spheres: The JKR-DMT transition using a Dugdale model, J. Colloid Interface Sci. 150 (1992) 243--269 Cite error: The named reference "Maugis1" was defined multiple times with different content (see the help page).

- ^ , Bowden, FP and Tabor, D., 1939, The area of contact between stationary and between moving surfaces, Proceedings of the Royal Society of London. Series A, Mathematical and Physical Sciences, 169(938), pp. 391--413.

- ^ Bowden, F.P. and Tabor, D., 2001, The friction and lubrication of solids, Oxford University Press.

- ^ Archard, JF, 1957, Elastic deformation and the laws of friction, Proceedings of the Royal Society of London. Series A, Mathematical and Physical Sciences, 243(1233), pp.190--205.

- ^ Greenwood, JA and Williamson, JBP., 1966, Contact of nominally flat surfaces, Proceedings of the Royal Society of London. Series A, Mathematical and Physical Sciences, pp. 300-319.

- ^ Bush, AW and Gibson, RD and Thomas, TR., 1975, The elastic contact of a rough surface, Wear, 35(1), pp. 87-111.

- ^ Persson, BNJ and Bucher, F. and Chiaia, B., 2002, Elastic contact between randomly rough surfaces: Comparison of theory with numerical results, Physical Review B, 65(18), p. 184106.

- ^ Shigley, J.E., Mischke, C.R., 1989, Mechanical Engineering Design, Fifth Edition, Chapter 2, McGraw-Hill, Inc, 1989, ISBN 0-07-056899-5.

- ^ Wriggers, P. 2006, Computational Contact Mechanics. 2nd ed. (Springer Verlag: Heidelberg).

- ^ Laursen, T. A., 2002, Computational Contact and Impact Mechanics: Fundamentals of Modeling Interfacial Phenomena in Nonlinear Finite Element Analysis, (Springer Verlag: New York).

- ^ Acary V. and Brogliato B., 2008,Numerical Methods for Nonsmooth Dynamical Systems. Applications in Mechanics and Electronics. Springer Verlag, LNACM 35, Heidelberg.

- ^ Popov, Valentin L., 2009, Kontaktmechanik und Reibung. Ein Lehr- und Anwendungsbuch von der Nanotribologie bis zur numerischen Simulation, Springer-Verlag, 328 S., ISBN 978-3-540-88836-9.

- ^ a b Sneddon, I. N., 1965, The Relation between Load and Penetration in the Axisymmetric Boussinesq Problem for a Punch of Arbitrary Profile. Int. J. Eng. Sci. v. 3, pp. 47–57.

- ^ Hyun, S., and M.O. Robbins, 2007, Elastic contact between rough surfaces: Effect of roughness at large and small wavelengths. Trobology International, v.40, pp. 1413-1422.

- ^ Bradley, RS., 1932, The cohesive force between solid surfaces and the surface energy of solids, Philosophical Magazine Series 7, 13(86), pp. 853--862.

- ^ Derjaguin, BV and Muller, VM and Toporov, Y.P., 1975, Effect of contact deformations on the adhesion of particles, Journal of Colloid and Interface Science, 53(2), pp. 314-326.

- ^ Muller, VM and Derjaguin, BV and Toporov, Y.P., 1983, On two methods of calculation of the force of sticking of an elastic sphere to a rigid plane, Colloids and Surfaces, 7(3), pp. 251-259.

- ^ Tabor, D., 1977, Surface forces and surface interactions, Journal of Colloid and Interface Science, 58(1), pp. 2-13.

- ^ Johnson, KL and Greenwood, JA, 1997, An adhesion map for the contact of elastic spheres, Journal of Colloid and Interface Science, 192(2), pp. 326-333.

- ^ Carpick, R.W. and Ogletree, D.F. and Salmeron, M., 1999, A general equation for fitting contact area and friction vs load measurements, Journal of colloid and interface science, 211(2), pp. 395-400.

External links

- [1]: More about contact stresses and the evolution of bearing stress equations can be found in this publication by NASA Glenn Research Center head the NASA Bearing, Gearing and Transmission Section, Erwin Zaretsky.

![{\displaystyle M_{x}=\int _{S}y~p(x,y)~\mathrm {d} A~;~~M_{y}=\int _{S}x~p(x,y)~\mathrm {d} A~;~~M_{z}=\int _{S}[x~q_{y}(x,y)-y~q_{x}(x,y)]~\mathrm {d} A}](https://wikimedia.org/enwiki/api/rest_v1/media/math/render/svg/a77a8e515e4705ee8e8a837b43c00288259dca3c)

![{\displaystyle {\begin{aligned}\sigma _{xx}&=-{\frac {2z}{\pi }}\int _{a}^{b}{\frac {p(x')(x-x')^{2}\,dx'}{[(x-x')^{2}+z^{2}]^{2}}}~;~~\sigma _{zz}=-{\frac {2z^{3}}{\pi }}\int _{a}^{b}{\frac {p(x')(x-x')^{2}\,dx'}{[(x-x')^{2}+z^{2}]^{2}}}\\\sigma _{xz}&=-{\frac {2z^{2}}{\pi }}\int _{a}^{b}{\frac {p(x')(x-x')\,dx'}{[(x-x')^{2}+z^{2}]^{2}}}\end{aligned}}}](https://wikimedia.org/enwiki/api/rest_v1/media/math/render/svg/6b470fc449f9bcdaa830abd9f20c0a8fbaedc0aa)

![{\displaystyle {\begin{aligned}\sigma _{xx}&=-{\frac {2}{\pi }}\int _{a}^{b}{\frac {q(x')(x-x')^{3}\,dx'}{[(x-x')^{2}+z^{2}]^{2}}}~;~~\sigma _{zz}=-{\frac {2z^{2}}{\pi }}\int _{a}^{b}{\frac {q(x')(x-x')\,dx'}{[(x-x')^{2}+z^{2}]^{2}}}\\\sigma _{xz}&=-{\frac {2z}{\pi }}\int _{a}^{b}{\frac {q(x')(x-x')^{2}\,dx'}{[(x-x')^{2}+z^{2}]^{2}}}\end{aligned}}}](https://wikimedia.org/enwiki/api/rest_v1/media/math/render/svg/58ddbeaedccc5f72051ed1e79a0369fc7ca75e83)

![{\displaystyle f(z)={\cfrac {16\gamma }{3z_{0}}}\left[\left({\cfrac {z}{z_{0}}}\right)^{-9}-\left({\cfrac {z}{z_{0}}}\right)^{-3}\right]}](https://wikimedia.org/enwiki/api/rest_v1/media/math/render/svg/823c39aa579bccfe83e16d8e0620be0c31da5f65)

![{\displaystyle F_{a}={\cfrac {16\gamma \pi R}{3}}\left[{\cfrac {1}{4}}\left({\cfrac {z}{z_{0}}}\right)^{-8}-\left({\cfrac {z}{z_{0}}}\right)^{-2}\right]~;~~{\frac {1}{R}}={\frac {1}{R_{1}}}+{\frac {1}{R_{1}}}}](https://wikimedia.org/enwiki/api/rest_v1/media/math/render/svg/a5e65f72a6bc43bd68353aa46db1e72b3b77db45)

![{\displaystyle \mu :={\cfrac {d_{c}}{z_{0}}}\approx \left[{\cfrac {R(\Delta \gamma )^{2}}{{E^{*}}^{2}z_{0}^{3}}}\right]^{1/3}}](https://wikimedia.org/enwiki/api/rest_v1/media/math/render/svg/b1347522bcc937bd029a2f9f119509b5bc119d46)

![{\displaystyle u^{H}(c)={\cfrac {1}{\pi R}}\left[a^{2}(2-m^{2})\sin ^{-1}\left({\cfrac {1}{m}}\right)+a^{2}{\sqrt {m^{2}-1}}\right]}](https://wikimedia.org/enwiki/api/rest_v1/media/math/render/svg/1470bfbf06fae768ff995219a88c987419b0f5c7)

![{\displaystyle p^{D}(r)={\begin{cases}-{\cfrac {\sigma _{0}}{\pi }}\cos ^{-1}\left[{\cfrac {2-m^{2}-{\cfrac {r^{2}}{a^{2}}}}{m^{2}\left(1-{\cfrac {r^{2}}{m^{2}a^{2}}}\right)}}\right]&\quad \mathrm {for} \quad r\leq a\\-\sigma _{0}&\quad \mathrm {for} \quad a\leq r\leq c\end{cases}}}](https://wikimedia.org/enwiki/api/rest_v1/media/math/render/svg/f95ec8099d70052f188d354692547479d581486b)

![{\displaystyle F^{D}=-2\sigma _{0}m^{2}a^{2}\left[\cos ^{-1}\left({\cfrac {1}{m}}\right)+a^{2}{\sqrt {m^{2}-1}}\right]}](https://wikimedia.org/enwiki/api/rest_v1/media/math/render/svg/0b953af304cad698034fed1bdcd2b0d698585474)

![{\displaystyle h^{D}(c)=\left({\cfrac {4\sigma _{0}a}{\pi E^{*}}}\right)\left[{\sqrt {m^{2}-1}}\cos ^{-1}\left({\cfrac {1}{m}}\right)+1-m\right]}](https://wikimedia.org/enwiki/api/rest_v1/media/math/render/svg/6098dbbc0e3b6776056d007f1a181e3068a07cd2)

![{\displaystyle {\bar {F}}={\bar {a}}^{3}-{\cfrac {4}{3}}~\lambda {\bar {a}}^{2}\left[{\sqrt {m^{2}-1}}+m^{2}\sec ^{-1}m\right]}](https://wikimedia.org/enwiki/api/rest_v1/media/math/render/svg/811917e9ea8fac3ddb18c96273e9509954daad2d)

![{\displaystyle {\cfrac {\lambda {\bar {a}}^{2}}{2}}\left[(m^{2}-2)\sec ^{-1}m+{\sqrt {m^{2}-1}}\right]+{\cfrac {4\lambda {\bar {a}}}{3}}\left[{\sqrt {m^{2}-1}}\sec ^{-1}m-m+1\right]=1}](https://wikimedia.org/enwiki/api/rest_v1/media/math/render/svg/1806071e425db2967826b4e1446fe19274d10326)