Conformal coating: Difference between revisions

Leehitchens (talk | contribs) |

Leehitchens (talk | contribs) |

||

| Line 44: | Line 44: | ||

====Solvent & Water based conformal Coatings==== |

====Solvent & Water based conformal Coatings==== |

||

[[File:DC100 Drying Cabinet for storage of wet circuit boards conformal coated.jpg|thumbnail| |

[[File:DC100 Drying Cabinet for storage of wet circuit boards conformal coated.jpg|thumbnail|right|100px|DC100 Drying Cabinet for storage of wet circuit boards conformal coated]] |

||

For standard solvent based acrylics, air drying (film forming) is the normal process except where speed is essential. Then accelerated heat curing can be used, using batch or inline ovens / conveyors and using typical cure profiles which are designed for maximally efficient curing without damage to the coating.<ref>{{cite web | url=http://www.conformalcoating.co.uk/documents/ConformalcoatingSolventBasedthermalcureprofileexample.pdf | title=Thermal profile cure process of a typical solvent based conformal coating | publisher=Conformalcoating.co.uk |accessdate=2010-08-27}}</ref> |

For standard solvent based acrylics, air drying (film forming) is the normal process except where speed is essential. Then accelerated heat curing can be used, using batch or inline ovens / conveyors and using typical cure profiles which are designed for maximally efficient curing without damage to the coating.<ref>{{cite web | url=http://www.conformalcoating.co.uk/documents/ConformalcoatingSolventBasedthermalcureprofileexample.pdf | title=Thermal profile cure process of a typical solvent based conformal coating | publisher=Conformalcoating.co.uk |accessdate=2010-08-27}}</ref> |

||

Revision as of 15:42, 27 March 2013

This article needs additional citations for verification. (October 2007) |

Conformal coating material is applied to electronic circuitry to act as protection against moisture, dust, chemicals, and temperature extremes that, if uncoated (non-protected), could result in damage or failure of the electronics to function. When electronics must withstand harsh environments and added protection is necessary, most circuit board assembly houses coat assemblies with a layer of transparent conformal coating rather than potting.[1]

Applications

Precision analog circuitry may suffer degraded accuracy if insulating surfaces become contaminated with ionic substances such as fingerprint residues, which can become weakly conductive in the presence of moisture. (The classic symptom of micro-contamination on an analog circuit board is sudden changes in performance at high humidity, for example when a technician breathes on it). Furthermore, a suitably chosen material coating has proved to actually reduce the effects of mechanical stress and vibrations on the circuit and its ability to cope in extreme temperatures.

For example, in a chip-on-board assembly process, a silicon die is mounted on the board with an adhesive or a soldering process, then electrically connected by wire bonding, typically with .001-inch-diameter gold or aluminum wire. The chip and the wire are very delicate, so they're encapsulated in a version of conformal coating called "glob top." This prevents accidental contact from damaging the wires or the chip. Another use of conformal coating is to increase the voltage rating of a dense circuit assembly; an insulating coating can withstand a much stronger electric field than air, particularly at high altitude.

With the exception of parylene, most organic coatings are readily penetrated by water molecules. A coating preserves the performance of precision electronics primarily by preventing ionizable contaminants such as salts from reaching circuit nodes, and combining there with water to form a microscopically thin electrolyte film. For this reason, coating is far more effective if all surface contamination is removed first, using a highly repeatable industrial process such as vapor degreasing or semi-aqueous washing in a special machine. Extreme cleanliness also greatly improves adhesion. Pinholes would defeat the purpose of the coating, because a continuous contaminant film would be able to make contact with the circuit nodes and form undesired conductive paths between them.

Coating methods

This section may require cleanup to meet Wikipedia's quality standards. The specific problem is: no images. (April 2009) |

The coating material can be applied by various methods, from brushing, spraying and dipping, or, due to the increasing complexities of the electronic boards being designed and with the 'process window' becoming smaller and smaller, by selectively coating via robot. Different methods of curing / drying are available depending on the conformal coating material.

Brush coating

This works by flow coating the material onto the board and is suitable for low volume application, finishing and repair. The finish tends to be inferior cosmetically and can be subject to many defects such as bubbles.[2] The coating also tends to be thicker and unless skilled operators applied the coating, highly subjective in quality.

Spray application coating

This coating can be completed with a spray aerosol or dedicated spray booth with spray gun and is suitable for low and medium volume processing.[3] The quality of the surface finish can be superior to all other methods when a trained skilled operator completes the process, as long as the circuit board is clean and the coating has no adhesion issues. The coating application may be limited due to 3D effects but masking requirements are more "shield" than "barrier" since the penetration is less effective. However, the lack of penetration can be an issue where coating is desired to penetrate under devices.

One of the key attributes of atomised spraying is giving excellent tip coverage to components. When conformal coatings are applied to a PCB they have a tendency to slump. The first layer of a coating can give a thin edge on the corner of components. This can be countered with a second coat through double dipping or over brushing but this is a repeat process and may not be acceptable. To counter this problem the technique of atomised spraying can be used.

Atomised spraying is the application of conformal coating using an aerosol or a batch spray gun when applied at a distance from the PCB where the coating fully atomises. The key here is the distance. Selective robotic coating does not atomise the coating when applied at 10-13mm off the printed circuit board and therefore the coating will slump on the edges of the components. This is not atomised spraying.

Atomised spraying builds up the layers of coating allowing the material to stick where it is applied. This prevents slumping and builds successive layers on the sharp edges. In fact, although conformal coating is not classed as a waterproofing material but is in fact a moisture barrier, the application of several layers of atomised coating can effectively “waterproof” the circuit board and give an impressive and effective barrier to water on the board.

Note, although it should be considered that even though the tip coverage is improved with this process, the coating application may be limited due to 3D effects. Further, there is a benefit that the masking requirements when spraying the coating are more "shield" than "barrier" compared to dipping since the penetration is less effective. However, the lack of penetration can be an issue where coating is desired to penetrate under devices.

Please also note, the optimum application technique for a particular PCB depends on several criteria such as material selection, volume of PCBs to be coated, budget, throughput speed, type of coverage required and ease of masking. Unfortunately, it can be a combination of factors that affect choice rather than individual factors and it is important to look at all the information collectively. The application of a liquid conformal coating material can be applied by various methods including brushing, spraying and dipping, selectively robotic spray and selective dip coating and the choice is critical.

Conformal coating dipping

This coating is a highly repeatable process and if the printed circuit board (PCB) is designed correctly, it can be the highest volume technique.[3] Coating penetrates everywhere, including under devices, and therefore any masking must be perfect to prevent leakage. Therefore, many PCBs are completely unsuitable for dipping due to design. The issue of "thin tip coverage" where the material slumps around sharp edges can be a problem especially in a highly condensing atmosphere. This tip coverage effect can be eliminated by either double dipping the PCB or using several thin layers of atomised spraying to achieve good coverage without exceeding coating thickness recommendations. A combination of the two techniques may also be used.

Typical robotic processes

This involves needle and atomised spray applicators, non-atomised spray or ultrasonic valve technologies that can move above the circuit board and dispense / spray the coating material in selective areas. Flow rates and material viscosity are programmed into the computer system controlling the applicator so that the desired coating thickness is maintained.[4] This method is highly effective at large volumes as long as the PCBs are designed for the method. However, there are limitations in the select coat process[5] like all the other processes, such as potential capillary effects around low profile connectors which "suck" up the coating accidentally.

The process quality of dip or dam-and-fill coating and non-atomised spray technology can be improved when necessary by applying and then releasing a vacuum while the assembly is submerged in the liquid resin. This forces the liquid resin into all crevices, eliminating uncoated surfaces in interior cavities.

The differences in application methods can be seen in a comparison presentation.[6] Choice of method is dependent on the complexity of the substrate to be conformally coated, the required coating performance, and the throughput requirements.

Curing and Drying

Solvent & Water based conformal Coatings

For standard solvent based acrylics, air drying (film forming) is the normal process except where speed is essential. Then accelerated heat curing can be used, using batch or inline ovens / conveyors and using typical cure profiles which are designed for maximally efficient curing without damage to the coating.[7]

Water based conformal coatings can be treated in the same manner but with more care with the application of the heat due to the slower drying times.

Conformal Coating Curing and Drying Definitions

The difference between drying and curing are important in processing.

Drying is where the coating is fit to be handled after application of conformal coating. Curing is where the optimum properties of the conformal coating are reached for full performance protection.

Actually, there are three stages that are useful to consider with most coatings. These are:

- Tack free – This is where the coating is dry enough to handle CAREFULLY.

- Fully dried – the conformal coating and PCB can be handled normally but the coating is not fully cured.

- Fully cured – Conformal coating has reached its optimum properties.

For all three stages, it may be that air drying at room temperature achieves the state required for the conformal coating. Alternatively, accelerated heat or moisture must be applied, or the application of UV light may be needed to achieve the desired result.

Do you Need to Fully Cure the Conformal Coating?

Curing implies that the optimum properties of the conformal coating are met, such as the electrical & physical characteristics, and that the conformal coating does not impede the operation of the printed circuit board (PCB).

A conformal coating could be applied to a PCB and after a period of two hours and look fully cured. However, this may not be the case. For instance, if a solvent based conformal coating is applied to a PCB and allowed to air dry at room temperature, although the board may be fit to handle, there would almost certainly be trace solvents after that period in the film which have not evaporated.

Also, with polyurethane conformal coatings, they have a characteristic of cross linking to give the chemical resistance they tend to be required for in the field. This cross linking can take days at room temperature, depending on the conformal coating chosen.

The question to ask then is a fully cured PCB with optimum properties required at each stage of the electronics manufacturing process and also in the period before service, where it may be held in storage or stock?

If the answer is no, then it’s unnecessary to fully cure. However, if the conformal coating affects the electrical output of a device that needs to be calibrated on the PCB and the output varies with curing then not fully curing before calibration could be a problem!

UV curing UV Conformal coatings

UV curing of conformal coatings is becoming increasingly important for high volume users in fields such as automotive and consumer electronics.

This increase in the popularity of UV curable conformal coatings is due to its rapid cure speed, level of processing ease, environmental friendliness and thermal cycling resistance, which have never before been achieved with UV conformal coating materials.[8]

There are different types of UV lights (lamps) used in curing conformal coatings and they are Arc and Microwave lamps.

UV Arc Lamps

The UV Arc Lamps are much lower in capital cost compared to the UV Microwave Lamp systems. The life time of a UV bulb is approx 500-1000 hours, depending how the UV lamp system is used, and, after this time the output power will degrade to be about 60% of the initial value.

This drop in power can be critical if the speed of the UV conveyor is approaching the limit of the UV cure ability of the lamp and the UV conformal coating and may need to be monitored. If the UV system is run slow enough this may not be an issue (relative to heat cure a slow speed is still pretty fast!).

The cost of the replacement UV bulbs are typically low cost depending upon the lamp fill, and a similar price to the microwave bulbs. It must also be noted that UV Arc Lamps also run a little hotter than the UV Microwave Lamps.

UV Microwave Lamps

The UV Microwave lamp bulb will last much longer than UV Arc lamp technology. Depending on the model, lifetime of the bulb can be quoted between 4000-8000 hours and one model guarantees 9000 hours. During this time there is very little power degradation. The UV lamp will not extinguish until the end of its life in this time period. The cost for the bulbs are similar.

Generally, as a rule of thumb if cost is very tight then its recommended that the UV Arc lamps are used, especially if there is low volume use and high speed is not critical. If it is higher volume, higher speed then we generally recommend UV Microwave Lamp technology since it is generally more economic and no maintenance is involved in monitoring the UV out put.

Thickness & Measurement

Coating material when dry (after curing) should typically have a thickness of 30–130 μm (0.0012–0.0051 in) when using acrylic resin, epoxy resin, or urethane resin. For silicone resin, the coating thickness recommended by the IPC standards is 50–210 μm (0.0020–0.0083 in).

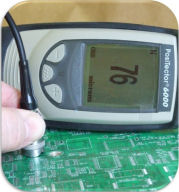

There are several methods for measurement of conformal coating thickness and they fall into two categories. These categories are wet film & dry film conformal coating measurements.

Wet Film Conformal Coating Measurement

The wet film conformal coating thickness method ensures quality control while the coating is still wet.

Applying too much coating can be expensive. Also, wet film measurements are useful for conformal coatings where the dry film thickness can only be measured destructively or over application of conformal coating could be problematic.

The wet film gauges are applied to the wet conformal coating and the teeth indicate the thickness of the conformal coating. The dry film thickness can then be calculated from the measurement.

Dry Film Conformal Coating Thickness Measurement

An alternative method to wet film measurement is using a non contact technique using eddy currents. The system works by placing the test head on the surface of the conformal coating, the measurement is almost instantaneous and provides an immediate repeatable result for thickness measurement of conformal coating.

Test coupons are the ideal method for measuring the coating thickness, whether is it spraying or dipping, and can be kept as a physical record of the performance. Apply the coating to the test coupons at the same time as the circuit boards provides a permanent measurement and an accurate guide to the coating thickness.

Thicker coatings or better applied coatings may be required when liquid water is present due to potential microscopic pinhole formation in the coating[2] or when the coating material is too thin on the sharp edges of components due to poor application techniques. The former effect is a defect and can be eliminated by appropriate steps and the latter has been mentioned previously. These techniques effectively "pot" or "conform" to the components by completely covering them.[citation needed]

Conformal Coating Inspection

Inspection of conformal coated circuit boards is a critical process that should be carried out on completion of the finishing process. However, it is often a neglected stage of the conformal coating process. The standards such as IPC-A-610 are explicit in their requirements for conformal coating inspection yet few companies actually inspect to that level.

Inspection is completed by two methods. The first is a manual process completed by an operator within a suitable space such as an inspection booth with a UV light source and the second is an automated process using a conformal coating AOI (Automated Optical Inspection) system.

Manual Conformal Coating Inspection

Manual Inspection of circuit boards after conformal coating application is the main method used by >95% of the electronics manufacturing world.

There are two critical points when considering inspection & finishing and they all relate to Creating the optimum environment.

First point is to provide the perfect conditions where an operator can easily inspect conformally coated circuit boards without fatigue to body or eyes. This will provide the highest quality results for the conformal coating process. Once this is complete the second critical factor is to provide a work space that will keep the operator safe from the harmful effects of solvents if they are used.

Complete these two points and the operator will have the perfect conditions for inspecting conformally coated circuit boards.

Automated Conformal Coating Inspection (AOI)

Automating a conformal coating inspection process can be a difficult process. The coating fluoresces and is transparent allowing the colours of the circuit board below to interfere with the analysis of the image. Link this to a 3D structure and this can be extremely problematic for high speed processing.

It has took a long time to develop AOI systems that can meet these challenges. However, one or two AOI company have specialised in this area and now provide camera and scanner based technologies which provide a range of solutions for conformal coating Automated Optical Inspection (AOI).

These systems address the IPC standards directly, ensuring that the criteria for inspection is met. The systems use UV LED lighting systems which optimise the image capture and they can address 3D issues using parallax free lens systems for their scanner systems.

Conformal Coating Selection

The selection of conformal coating material is a crucial factor that needs to be considered carefully and in relation to the application method.[9] The wrong selection can not only affect the long term reliability of the circuit board but can cause massive difficulties with both processing and costs.

The most common[citation needed] standards for conformal coating are IPC A-610[10] and IPC-CC-830.[11] These standards list indications of good and bad coverage and describe various failure mechanisms such as dewetting[12] and orange peel.[13]

Conformal coating inspection is a critical factor in determining successful coating application and long term reliability of PCBs. Using the IPC standards allows the coating operator to monitor the coating application performance. This can be done manually by the operator in an inspection booth by examining the PCB under white and UVA light or it can be done automatically by a conformal coating inspection system.

Another type of coating called parylene is applied with a vacuum deposition process versus a spray or needle application. The parylene is applied at the molecular level by a vacuum deposition process at ambient temperature. Film coatings from 0.100 to 76 μm can be easily applied in a single operation. The advantage of parylene coatings is that they cover hidden surfaces and other areas where spray and needle application are not possible. Coating thickness is very uniform, even on irregular surfaces. The three main disadvantages are that (i) any desired contact points such as battery contacts or connectors must be carefully covered with an air-tight mask to prevent the parylene from coating the contacts, (ii) it is a batch process and does not lend itself to high volume processing, and (iii) the cost per PCB can be highly prohibitive due to the capital investment costs and the cost per batch.

Coating Chemistries

There are many chemistries of conformal coatings out on the market today. While the "Material Considerations" section below is very important to finding the correct conformal coating, it is also important to find a coating chemistry meeting the application needs. Below are five common strengths for each conformal coating chemistry.[14]

- Acrylic

- Ease of rework

- Simple drying process

- Good moisture resistance

- High Fluorescence level

- Ease of viscosity adjustment

- Epoxy

- Useful to about 150C [302F]

- Harder durometer, abrasion resistance

- CTE closer to epoxy PCB substrate

- Higher Tg (Glass transition)

- Good dielectric properties

- Polyurethane

- Good dielectric properties

- Good moisture resistance

- Solvent resistance

- Less reversion potential

- Abrasion resistance

- Silicones

- Stable over wide temperature range (in general, -40C to 200C)[-40F to 392F]

- Flexible, provides dampening and impact protection

- Good moisture resistance

- High dielectric strength

- Low surface energy for better wetting

- Fluorinated or non Fluorinated - Poly-Para-Xylylene (Parylene)

- Excellent uniformity regardless of part geometry

- Chemical inertness

- Minimal added mass and low outgassing

- Low environmental impact process

- Low dielectric constant

- Amorphous Fluoropolymer

- Low dielectric constant

- High glass transition temperature

- Low surface energy

- Low water absorption

- Solvent resistance

The basics of conformal coating processing can be understood from a presentation available giving a summary of the areas covered above.[15]

Material considerations

Selection of the correct choice of coating material (lacquer) is one of the process engineer's most critical decisions. Criteria for selection must be based on answering many questions, which will include:

- What is being protected against? (e.g., moisture, chemicals)

- What temperature range will the electrical device encounter?

- What are the physical, electrical, and chemical requirements for the coating material itself?

- Electrical, chemical, and mechanical compatibility with the parts and substances to be coated (for instance, does it need to match the coefficient of expansion of chip components?)

Answers will determine the suitability of a particular material, be it acrylic, polyurethane, silicone, epoxy, etc. Process, production and commercial issues will then enter the equation:

- How easily can the material be reworked once applied?[16]

- How fast does the material dry (cure)?[17]

- How fast can the material be applied and dried (throughput time)?[17]

- What type of process and equipment is necessary to achieve the required coating quality (uniformity and repeatability)?[18]

- Price of the material per litre.[citation needed]

- Quality of the material supplier (two acrylic material manufacturers will not make equal quality of material).[citation needed]

References

- ^ Template:Dmoz

- ^ a b "Common failure mechanisms in conformal coating: Pin holes,Bubbles and Foam" (PDF). Conformalcoating.co.uk. Retrieved 2010-08-27.

- ^ a b "Setting up a Conformal Coating Spray Facility" (PDF). Conformalcoating.co.uk. Retrieved 2010-08-27.

- ^ "Conformal Coating Thickness Measurement Systems". Conformalcoating.co.uk. Retrieved 2010-08-27.

- ^ "Technical Bulletin September" (PDF). Conformalcoating.co.uk. Retrieved 2010-08-27.

- ^ "Conformal Coating Application Techniques". Slideshare.net. Retrieved 2010-07-26.

- ^ "Thermal profile cure process of a typical solvent based conformal coating" (PDF). Conformalcoating.co.uk. Retrieved 2010-08-27.

- ^ "Bulletin April" (PDF). Retrieved 2010-07-26.

- ^ "Technical Bulletin May" (PDF). Conformalcoating.co.uk. Retrieved 2010-08-27.

- ^ "Acceptability of Electronic Assemblies" (PDF). Retrieved 2010-08-27.

- ^ "Qualification and Performance of Electrical Insulating Compound for Printed Wiring Assemblies" (PDF). Retrieved 2010-07-26.

- ^ "Common failure mechanisms in conformal coating: De-wetting" (PDF). Conformalcoating.co.uk. Retrieved 2010-08-27.

- ^ "Bulletin Jan 09 Conformal Coating failure mechanisms Orange Peel" (PDF). Retrieved 2010-07-26.

- ^ "Conformal Coating Comparison Guide". ElectronicCoating.com. Retrieved 2010-08-18.

- ^ "Basic Concepts Of Conformal Coating". Slideshare.net. Retrieved 2010-07-26.

- ^ "Technical Bulletin June" (PDF). Conformalcoating.co.uk. Retrieved 2010-08-27.

- ^ a b "Conformal_coating_drying_and_curing_FAQs". Conformalcoating.co.uk. Retrieved 2010-07-26.

- ^ "Technical Bulletin November" (PDF). Conformalcoating.co.uk. Retrieved 2010-08-27.

External links

- http://www.conformalcoating.co.uk/documents/BulletinNovember.pdf Conformal Coating application techniques

- http://www.ausbond.com/Product.asp?bigclassname=Conformal+Coatings

- http://www.electroniccoating.com/our-process-materials/materials/ List of different conformal coating chemistries