AC power plugs and sockets: Difference between revisions

Binksternet (talk | contribs) Reverted 1 edit by Thermocouple K Welder (talk): Rv promo. (TW) |

m →Italian Bticino brand Magic security connector: lang change |

||

| Line 787: | Line 787: | ||

}} |

}} |

||

This style of connector, produced by Italian manufacturer Bticino, appeared in the 1960s and was intended as an alternative to the Europlug or CEI 23-16/VII connectors then in use.<ref name="Cesco G. 1975. P 73">De Cesco G.: Acqua Luce Gas. Manuali pratici del far da sé. I Jolly bricolage. Fratelli Fabbri Editori, Milano, 1975. P 73.</ref> The socket is an almost rectangular socket, with one or more lateral key pins and indentations to prevent inverting the plug |

This style of connector, produced by Italian manufacturer Bticino, appeared in the 1960s and was intended as an alternative to the Europlug or CEI 23-16/VII connectors then in use.<ref name="Cesco G. 1975. P 73">De Cesco G.: Acqua Luce Gas. Manuali pratici del far da sé. I Jolly bricolage. Fratelli Fabbri Editori, Milano, 1975. P 73.</ref> The socket is an almost rectangular socket, with one or more lateral key pins and indentations to prevent inverting the polarised plug, or connecting plugs and sockets with different current ratings. At least four models were produced: three single-phase general purpose connectors rated respectively 10 A, 16 A and 20 A; plus a three-phase industrial connector rated 10 A; all of them have different key-pin positioning so plugs and sockets cannot be mismatched.<ref>De Cesco G.: Acqua Luce Gas. Manuali pratici del far da sé. I Jolly bricolage. Fratelli Fabbri Editori, Milano, 1975. P 75.</ref> The socket is closed by a safety lid (bearing the word ‘’Magic’’ on it) which can be opened only with an even pressure on its surface, thus preventing the insertion of objects (except the plug itself) inside the socket. The contacts are blades positioned on both sides of the plug; the plug is energized only when it is inserted fully into the socket. |

||

The obvious drawback of the system is that it is not compatible with Europlugs. As household appliances were never sold fitted with these security plugs and the use of adapters would defeat all of the newly introduced safety features, once this system is adopted all standard plugs must be cut off and replaced with the appropriate security connector. However, the ''Magic'' security system had some success at first because its enhanced safety features appealed to customers; standard connectors of the day were considered not safe enough.<ref name="Cesco G. 1975. P 73"/> The decline of the system occurred when safety lids similar to the Magic type were developed (VIMAR Sicury<ref>[http://www.vimar.eu/index.php?l=it&module=articles&class=articles&event=__default&menu_item_id=134&content=20 La ricerca della sicurezza. Il brevetto Sicury] www.vimar.eu. Retrieved 12 February 2009.</ref>) and then applied to standard sockets by third brands and by Bticino itself. |

The obvious drawback of the system is that it is not compatible with Europlugs. As household appliances were never sold fitted with these security plugs and the use of adapters would defeat all of the newly introduced safety features, once this system is adopted all standard plugs must be cut off and replaced with the appropriate security connector. However, the ''Magic'' security system had some success at first because its enhanced safety features appealed to customers; standard connectors of the day were considered not safe enough.<ref name="Cesco G. 1975. P 73"/> The decline of the system occurred when safety lids similar to the Magic type were developed (VIMAR Sicury<ref>[http://www.vimar.eu/index.php?l=it&module=articles&class=articles&event=__default&menu_item_id=134&content=20 La ricerca della sicurezza. Il brevetto Sicury] www.vimar.eu. Retrieved 12 February 2009.</ref>) and then applied to standard sockets by third brands and by Bticino itself. |

||

Revision as of 13:38, 26 January 2014

AC power plugs and sockets are devices that allow electrically operated equipment to be connected to the primary alternating current (AC) power supply in a building. Electrical plugs and sockets differ in voltage and current rating, shape, size and type of connectors. The types used in each country are set by national standards, some of which are listed in the IEC technical report TR 60083, Plugs and socket-outlets for domestic and similar general use standardized in member countries of IEC.[1]

Plugs and sockets for portable appliances started becoming available in the 1880s, to replace connections to light sockets with easier to use wall-mounted outlets. A proliferation of types developed to address the issues of convenience and protection from electric shock. Today there are approximately 20 types in common use around the world, and many obsolete socket types are still found in older buildings. Co-ordination of technical standards has allowed some types of plugs to be used over wide regions to facilitate trade in electrical appliances, and for the convenience of travellers and consumers of imported electrical goods. Some multi-standard sockets allow use of several different types of plugs; improvised or unapproved adapters between incompatible sockets and plugs may not provide the full safety and performance of an approved adapter.

Concepts and terminology

Generally the plug is the movable connector attached to an electrically operated device's mains cable, and the socket is fixed on equipment or a building structure and connected to an energised electrical circuit. The plug has protruding prongs, blades, or pins (referred to as male) that fit into matching slots or holes (called female) in the sockets. Sockets are designed to prevent exposure of bare energised contacts. Sockets may also have protruding exposed contacts, but these are used exclusively for earthing (grounding).

To reduce the risk of users accidentally touching energized conductors and thereby experiencing electric shock, plug and socket systems often incorporate safety features in addition to the recessed slots or holes of the energized socket. These may include plugs with insulated sleeves, recessed sockets, sockets with blocking shutters, and sockets designed to accept only compatible plugs inserted in the correct orientation.

The term plug is in general and technical use in all forms of English, common alternatives being power plug,[2] electric plug,[3] and (in the UK) plug top.[4] The normal technical term (in both British and International English) for an AC power socket is socket-outlet,[5] but in non-technical common use a number of other terms are used. In British English the general term is socket, but there are numerous common alternatives, including power point,[6] plug socket,[7] wall socket,[8] and wall plug.[9] In American English receptacle and outlet are common, sometimes with qualifiers such as wall outlet, electrical outlet and electrical receptacle, all of these sometimes to be found in the same document.[10] A socket may be surrounded by a decorative and/or protective cover called a wall plate, face plate, outlet cover,[11] socket cover, or wall cover. In some designs this is an integral piece with the socket itself, bought and installed as a single unit.

Electrical sockets for single phase domestic, commercial and light industrial purposes generally provide either two or three electrical connections to the supply conductors. All two pin sockets provide neutral and line connections, both of which carry current and are defined as live parts.[12][13] Neutral is usually at or very near to earth potential, usually being earthed either at the distribution board or at the substation. Line (also known as phase or hot, and commonly, but technically incorrectly, as live,) carries the full supply voltage relative to the neutral (and to earth). Three pin sockets provide, in addition, a protective earth[14] connection. This allows the exposed metal parts of the appliance to be connected to earth (also known as ground), providing protection to the user should those exposed parts inadvertently come into contact with any live parts within the appliance. Some sockets may carry two line connections, each at half the supply voltage relative to the (sometimes missing) neutral but the full voltage relative to each other (NEMA 14-30 is an example). Industrial and multiphase power plugs and sockets may have more than one line conductor, particularly if connected to three phase power systems.

History

Early history

When electricity was first introduced into houses, it was primarily used for lighting. At that time, many electricity companies operated a split-tariff system where the cost of electricity for lighting was lower than that for other purposes. This led to portable appliances (such as vacuum cleaners, electric fans, and hair driers) being connected to light bulb sockets using lampholder plugs.[15]

As electricity became a common method of operating labour-saving appliances, a safe means of connection to the electric system other than using a light socket was needed. According to British Author John Mellanby[16] the first plug and socket in England was introduced by T.T. Smith in 1883, and there were two-pin designs by 1885, one of which appears in the (British) General Electric Company Ltd. catalogue of 1889. Gustav Binswanger, a German immigrant who founded the (British) General Electric Company Ltd, obtained a patent (GB189516898) in 1895 for a plug and socket using a concentric (co-axial) contact system.

An early American electrical plug and socket was invented by Harvey Hubbell and patented in 1904. Hubbell's first design was a socket which screwed into a lampholder (like the early lampholder plugs), but with a seperable plug with pins or blades (U.S. patent 774,250). Other manufacturers adopted the Hubbell pattern and by 1915 they were widespread. Gradually wall sockets were developed to supplement those that screwed into lampholders.[17][18][19]

The earthed consumer plug has several claimants to its invention. A 1911 book[20] dealing with the electrical products of A. P. Lundberg & Sons of London describes the Tripin earthed plug available in 2.5 Amp and 5 Amp models. The pin configuration of the Tripin appears virtually identical to modern BS 546 plugs. In her 1914 book Electric cooking, heating, cleaning, etc[21] Maud Lucas Lancaster mentions an earthed iron-clad plug and socket by the English firm of Reyrolle and Co. The earliest American patent application for an earthed plug appears to be 11 January 1915 by George P. Knapp, on behalf of the Harvey Hubbell company.[22] This patent covers the use of an earthing pin which extends further than the other two contacts to ensure that it is engaged first. The configuration of the socket was not operable with existing two-contact unearthed plugs. Other earthed sockets that are widely used today are operable with unearthed plugs.

The German Schuko-system plug was patented by Albert Büttner in 1926.[23] The current American version of the earthed plug, with two parallel blades and a round earthing pin, was invented by Philip F. Labre, while he was attending the Milwaukee School of Engineering. It is said that his landlady had a cat which would knock over her fan when it came in the window. When she plugged the fan back in, she would get an electric shock. Labre deduced that if the fan was earthed, the electricity would go to earth through the plug rather than through the person holding it. He was issued a US patent for an earthed socket and plug in 1928.[24] As the need for safer installations became apparent, earthed three-contact systems were made mandatory in most industrial countries.

Proliferation

During the first fifty years of commercial use of electric power, standards developed rapidly based on growing experience. Technical, safety, and economic factors influenced the development of all wiring devices and numerous varieties were invented. Gradually the desire for trade eliminated some standards that had been used in only a few countries.

Former colonies may retain the standards of the colonising country. Sometimes offshore industrial plants or overseas military bases use the wiring practices of their controlling country instead of the surrounding region.

Some countries have multiple voltages, frequencies and plug designs in use, which can create inconvenience and safety hazards. Hotels and airports may maintain sockets of foreign standards for the convenience of travellers.

Consolidation

De facto standards became formalised as official national and international standards. Old installations with obsolete sockets exist. The International Electrotechnical Commission in 1934 established technical committee TC 23 for electrical fittings. Only two meetings were held before the outbreak of the Second World War.[25] In Europe, since 1951 the International Commission on the Rules for the Approval of Electrical Equipment (CEE) has published a standard (CEE 7 Specification for Plugs and Socket-Outlets for Domestic and Similar Purposes[26]) describing the plugs and sockets used.In 1953 the CEE published Technical Report 83, (later 60083) which was a listing of plugs and sockets then in use. In North America the National Electrical Manufacturers' Association publishes standards for plugs and sockets.

Consolidation of standards eases international trade and travel. For example, the CEE 7/7 plug has been adopted in several European countries and is compatible with both CEE 7/5 and CEE 7/4 sockets, while the unearthed and unpolarised Europlug is compatible with an even greater proportion of European and other socket types. IEC 60906-1 has been proposed as a common standard for all 230 V plugs and sockets worldwide but has only been adopted in South Africa so far, with a modified version used in Brazil. IEC 60906-2 recognizes the wide use of the NEMA 5-15 parallel blade plug and socket and recommends it for all 120 V applications.

Application issues

Design features of plugs and sockets have gradually developed to reduce the risk of electric shock and fire. Safety measures may include pin and slot dimensions and layout that permit only proper insertion of plug into socket, and earth pins longer than power pins so the device becomes earthed before power is connected. Electrical insulation of the pin shanks was added to some designs, to reduce live contact exposure when a plug is partially inserted in a socket. Shutters that open only for the correct plug prevent foreign objects from contacting live slots. Some types include fuses and switches.

Earthing (grounding)

A third contact for a connection to earth is intended to protect against insulation failure of the connected device. When earthed distribution systems became common, earlier unearthed socket types were either replaced with new standards, or revised to include an earthing pin.

Different types of plugs are used for different IEC appliance classes. The assigned class depends on whether or not the device is earthed, and the degree of insulation it incorporates. Class I, for example, refers to earthed equipment which requires a third contact in the plug and socket, while Class II refers to unearthed equipment protected by double insulation.

Polarization

Where the building wiring system defines a "neutral" conductor that is connected to earth, it is an advantage for appliance designers to preserve that distinction. This requires a plug that can only be connected in one way to the socket, so that the energised and neutral conductors are not interchanged. In most designs, such "polarized" plugs cannot be mated with non-polarized sockets. Wiring systems where both circuit conductors have a significant potential with respect to earth do not benefit from polarized plugs.

Polarization is maintained by the shape, size, or position of plug pins and socket holes to ensure that a plug fits only one way into a socket. The (single pole) switch of the appliance is then connected in series with the energized wire. For an appliance such as a toaster, putting the exposed heating wires on the neutral side of the switch provides a small measure of extra protection against electrical shock; similarly, lamps with Edison screw bases will connect the screw shell of the lamp socket to the neutral conductor.

Interchange hazards

Plugs and sockets are designed as a system to meet standards for safety and reliability. Some types of socket may accept more than one type of plug; where this is an official, approved intention of the socket design, all the approved combinations will be tested to the applicable safety standards. Occasionally, plug and socket combinations may allow power to flow but may not meet product standards for mating force, earthing, current capacity, life expectancy, or safety. Improvised or user-modified connectors will not meet the product safety standards. Adapters between different standards can overcome mechanical incompatibility. Physical compatibility does not ensure that the appliance and socket match in frequency or voltage.

Appliance connections and extensions

So that manufacturers need not build, distribute and maintain many similar appliances differing only in the type of plug fitted, a common strategy is to provide an IEC 60320 inlet on the appliance and a detachable power cord (mains flex lead) to allow connection of the appliance to the socket. The appliance need only to be tested to the power inlet. Some types of appliance require the consumer to also change a switch to adapt to different voltages or frequency. In addition to sockets permanently attached to building wiring, extension cords (extension leads) are used for temporary connections when a socket is not within convenient reach of an appliance's power lead. Portable equipment such as gardening power tools may have a male power inlet compatible with the connector at the end of an extension cord; this allows one long cord to be shared among several tools, and so saves storage space and cost for the consumer. Multiple small appliances may be connected to sockets on a power strip which can also include switching, surge voltage and over-current protection; a power strip equipped with different series of plug and sockets can act as an adapter for imported equipment.

Special purpose plugs and sockets

Special purpose sockets may be found in residential, industrial, commercial or institutional buildings. Examples of systems using special purpose sockets include:

- "Clean" (low electrical noise) earth for use with computer systems,

- Emergency power supply,

- Uninterruptible power supply for critical or life-support equipment,

- Isolated power for medical instruments, tools used in wet conditions, or electric razors,

- "Balanced" or "technical" power used in audio and video production studios,

- Theatrical lighting,

- Sockets for electric clothes dryers, electric ovens, and air conditioners with higher current rating.

Special-purpose sockets may be only labelled or coloured to identify a reserved use of a system, or may have keys or specially shaped pins to prevent use of unintended equipment.

Types in present use

There are two basic standards for voltage and frequency in the world. One is the North American standard of 120 volts at a frequency of 60 Hz, and the other is the European standard of 220–240 volts at 50 Hz. The differences arose for historical reasons as discussed in the article mains electricity.

The IEC maintains a Web page giving arbitrary letter designations for generally compatible types of plugs. The IEC Web page does not identify the national standards corresponding to each plug letter. Letter designations were given in a 1998 US government publication,[27] intended as a guide for Americans travelling or working in other countries. The letter codes are often used as a de facto naming standard when comparing different AC power plugs, especially when describing traveller's adapters. Physically identical sockets may be connected to voltages incompatible with an appliance. The letter codes do not identify all the variants of a plug and socket family for different current ratings or for special purposes.

In Europe, the European Committee for Electrotechnical Standardization (CENELEC) publishes a list of approved plug and socket standards used in the member countries.[28]

Argentina IRAM 2073 & 2071 and compatible types (Type I)

The plug and socket used in Class 1 applications in Argentina is defined by IRAM. The applicable standards are: IRAM 2073 "Two poles plugs with earthing contact for domestic and similar purposes, rated 10 A and 20 A, 250 V a.c." and IRAM 2071 "Two pole socket - outlets with earthing contact for 10 A and 20 A, 250 V a.c, for fixed installations. " It is similar in appearance to the Australasian and Chinese plugs. The pin length is same as the Chinese version. The most important difference from the Australian plug is that the Argentinian plug is wired with the line and neutral contacts reversed.

In Brazil, this kind of plug and socket is still commonly used for high-power appliances like air conditioners, dishwashers, and household ovens. Since Brazil adopted the NBR 14136 standard which includes a 20 A version, the original motivation to use the "Argentinian" plug has ceased to exist.[citation needed]

Australian standard AS/NZS 3112 (Type I)

The plug used in Australia, New Zealand, Fiji, Tonga, Argentina, Solomon Islands, Papua New Guinea and China has an earthing pin and two flat current-carrying pins forming an upside down V-shape.[29] The flat blades measure 6.5 by 1.6 mm (0.256 by 0.063 in) and are set at 30° to the vertical at a nominal pitch of 13.7 mm (0.539 in). Australian and New Zealand wall sockets almost always have switches on them for extra safety, as in the UK. An unearthed version of this plug with two angled power pins but no earthing pin is used with small double-insulated appliances, but the sockets always include an earth pin.

There are several AS/NZS 3112 plug variants,[30] including ones with larger or differently shaped pins used for devices drawing 15, 20, 25 and 32 A. These sockets accept plugs of equal or of a lower current capacity, but not of higher capacity. For example, a 10 A plug will fit all sockets but a 20 A plug will fit only 20, 25 and 32 A sockets.

Australia's standard plug/socket system was originally codified as standard C112 (floated provisionally in 1937, and adopted as a formal standard in 1938), which was superseded by AS 3112 in 1990. The requirement for insulated pins was introduced in the 2004 revision.[31] The current version is AS/NZS 3112:2011, Approval and test specification—Plugs and socket-outlets.

Brazilian standard NBR 14136 (Type N)

Brazil, which had been using mostly Class II Europlugs, and NEMA 1–15 and NEMA 5–15 standards, adopted a modified (non-compliant) version of IEC 60906-1 as the national standard in 1998 (revised in 2002) under specification NBR 14136.[32] There are two types of sockets and plugs in NBR 14136: one for 10 A, with a 4 mm pin diameter, and another for 20 A, with a 4.8 mm pin diameter, the latter used for heavier appliances such as microwave ovens.[33] NBR 14136 was not enforced or encouraged in that country until 2007, when its adoption was made optional for manufacturers, becoming compulsory on January 1, 2010. It helped domestic consumers that most of Class II plugs fitted in the new NBR 14136 sockets.

British and compatible standards

BS 546 and related types (Type D & M)

BS 546, "Two-pole and earthing-pin plugs, socket-outlets and socket-outlet adaptors for AC (50-60 Hz) circuits up to 250V" describes four sizes of plug rated at 2 A, 5 A (Type D), 15 A (Type M) and 30 A. The plugs have three round pins arranged in a triangle, with an earthing pin. The plugs are polarized and unfused. Plugs are non-interchangeable between current ratings. Introduced in 1934, the BS 546 type has mostly been displaced in the UK by plugs and sockets to the BS 1363 standard. According to the IEC[34][unreliable source?] some 40 countries use Type D and 15 countries use Type M. Some, such as India and South Africa, use standards based on BS 546.

BS 1363 (Type G)

BS 1363 "13 A plugs, socket-outlets, adaptors and connection units"[35] is the main plug and socket type used in the United Kingdom. According to the IEC[34][unreliable source?] it is also used in over 50 countries worldwide, many of which have national standards based on BS 1363, including: Ireland, Malaysia, Singapore, and Saudi Arabia.

This plug, commonly called a 13 A plug or 13 amp plug, has three rectangular pins forming an isosceles triangle. As the BS 1363 socket is conventionally used with ring circuits the plug has a fuse to protect the appliance flexible cable from overload.

BS 4573 (UK shaver)

In the United Kingdom and Ireland, there is a two-pin plug and socket for use with electric shavers and toothbrushes.[36] The plug has insulated sleeves on the pins. The BS 4573 socket is suitable for use in dry areas only, so is rarely used. It is more usual to find shaver supply units meeting BS EN 61558-2-5 which include an isolation transformer and usually accept multiple two-pin plug types including BS 4573, Europlug and Australian and sometimes a 115 V output for two-pin US plugs.

CEE 7 standards and Europlug

A number of standards based on two round pins with centres spaced at 19 mm are in use in continental Europe and elsewhere. The sockets are generally compatible with the CEE 7/16 Europlug as well as the corresponding plug type. The Europlug has two pins 4 mm diameter spaced 18.5 mm on centers at the base. The pins are slightly flexible, which allows the Europlug to fit several types of CEE standard sockets.

CEE 7/4 (German "Schuko")(Type F)

CEE 7/4, commonly called "Schuko" socket, has a recessed round shape with two symmetrical round sockets and two earthing clips on the sides of the socket. The Schuko connection system is symmetrical and unpolarised in its design, allowing line and neutral to be reversed. Its dimensions are compatible with CEE 7/5 (French plug/socket) except that the female earth contact is omitted. The socket also accepts Europlugs and CEE 7/17 plugs. It supplies up to 16 A. The current German standards are DIN 49441:1972-06 "Two-pole plugs with earthing-contact 10 A 250 V≅ and 10 A 250 V–, 16 A 250 V∼" (which also includes CEE 7/7 plug) and DIN 49440-1:2006-01 "Two-pole socket-outlets with earthing contact, 16 A 250 V a.c." It is also used in Albania, Austria, Bosnia and Herzegovina, Bulgaria, Chile, Croatia, Denmark, Estonia, Finland, Greece, Hungary, Iceland, Indonesia, Iran, Italy, Latvia, Lithuania, Luxembourg, Republic of Macedonia, Republic of Moldova, the Netherlands, Norway, Pakistan, Portugal, Romania, Russia,[37] Serbia, Slovenia, South Korea, Spain, Sweden, Turkey, Ukraine, and Uruguay.

It is also defined as the Class I plug in Italian standard CEI 23-5. (CEE 7/17 is defined as the class II plug in CEI 23-5.)

"Schuko" is an abbreviation for the German word Schutzkontakt, which means "Protective contact" - in this case "protective" refers to the earth.

Some countries, including Finland, Denmark,[38] Norway and Sweden, require child-proof socket shutters; the German Schuko standard does not have this requirement.

CEE 7/5 (French)(Type E)

French standard NF C 61-314 "Plugs and socket-outlets for household and similar purposes" (which also includes CEE 7/7, 7/16 and 7/17 plugs) defines a round plug with two round pins measuring 4.8 by 19 mm (0.189 by 0.748 in), spaced 19 mm (0.748 in) apart and with a hole for the socket's earth pin. This standard is also used in Belgium, Poland, the Czech Republic, Slovakia and some other countries. Although the plug is polarised, there is no universally observed standard for placement of the line and neutral. However, the Czech standard recommends the line wire to be on the left side when facing the socket. Add to that the French convention changed circa 2002 from nothing particular, to, if the earth pin was at the top then the line hole in the socket would be on the right looking at the socket. However, the socket may not necessarily be installed with the earth pin at the top. Packaging in France of said sockets is normally marked with correct orientation of the cables. Polarised pre fitted plugs on appliances are therefore connected with the brown to the right pin and the blue to the left, the earth being connected to the hole at the "top" of the plug.

CEE 7/4 plugs are not compatible with the CEE 7/5 socket because earthing in the CEE 7/5 socket is via a round male pin permanently mounted in the socket.

CEE 7/7

To bridge the differences between German and French standards, the CEE 7/7 plug was developed. It is polarised to prevent the line and neutral connections from being reversed when used with a French CEE 7/5 socket, but allows polarity reversal when inserted into a German CEE 7/4 socket. The plug is rated at 16 A.

It has earthing clips on both sides to connect with the CEE 7/4 socket and a female contact to accept the earthing pin of the CEE 7/5 socket. It is used in almost all European countries. Currently, appliances are sold with non-rewireable CEE 7/7 plugs attached. This means that the plugs are now identical between countries like France and Germany, but the sockets are different.

CEE 7/16 "Europlug" (Type C)

This two-pin plug, rated at 2.5 A, is popularly known as the Europlug. The plug is unearthed and has two round 4 mm (0.157 in) pins, which usually converge slightly towards their free ends. It is not rewirable and must be supplied with a flexible cord. It is defined by Cenelec standard EN 50075 "Flat non-rewirable two-pole plugs, 2,5 A 250 V, with cord, for the connection of class II-equipment for household and similar purposes" which has national equivalents in most European countries, as described in IEC 60083. Because it is unpolarised, it can be inserted in either direction into a socket, so line and neutral are connected arbitrarily. The separation and length of the pins allow its safe insertion in most CEE 7/5, CEE 7/4 "Schuko", Israeli, CEE 7/7, Swiss, Danish and Italian sockets. Most modern UK dedicated shaver sockets designed to accept BS 4573 shaver plugs also accept Europlugs for applications requiring less than 200 mA.[39]

The Europlug itself is used in class II applications throughout continental Europe. It is also used in the Middle East (Iran), most African nations, South America (Brazil, Chile, Argentina, Peru and Bolivia), Asia (India, Bangladesh, Sri Lanka, Indonesia, Pakistan, and South Korea) as well as Russia and the former Soviet republics, such as Ukraine, Armenia, Georgia, and many developing nations. It is also used alongside the BS 1363 in many nations, particularly former British colonies.

CEE 7/17 (German/French)

This plug also has two round pins but the pins are 4.8 mm (0.189 in) in diameter like CEE 7/5 and CEE 7/4 and the plug has a round plastic or rubber base that stops it being inserted into small sockets intended for the Europlug. Instead, it fits only into large round sockets intended for CEE 7/5 and CEE 7/4. The base has holes in it to accommodate both side contacts and socket earth pins. It is used for large appliances, and in South Korea for all domestic non-earthed appliances. It is also defined as the Class II plug in Italian standard CEI 23-5. It can also be inserted in to Israeli SI 32 with some difficulty. The Soviet GOST 7396 standard includes both the CEE 7/17 plug and a variant with shape of the CEE 7/17 plug but with the 4.0 mm (0.157 in) diameter pins used in the Europlug.

Unearthed sockets

Round unearthed sockets have no earth provisions and consequently have been phased out in most countries. (For example, Sweden prohibited them from new installations in 1994.) Countries using the CEE 7/5 and CEE 7/4 standards vary in whether unearthed round sockets are still permitted in environments where the need for earthing is less critical.

Some countries prohibit use of unearthed and earthed sockets in the same room, in the "insulated room" concept, so that people cannot touch an earthed object and one that has become live, at the same time. For example, in Germany, unearthed sockets are rare, found only in very old installations, whereas in the Netherlands they are common in "dry areas" such as in bedrooms or living rooms.

Standards also vary between countries as to whether child-resistant shutters are required. The depth of the sockets also vary between countries and age. Older sockets are so shallow that it is possible to touch the pins of a plug when the plug is inserted deep enough to get electrical power on the pins, while newer sockets are deep enough to protect from this kind of accident. Depending on the country and the age of the socket these may have 4.0 or 4.8 mm sockets. (4.0 mm are usually similar to 6 A GOST 7396 type C1 and 4.8 mm are usually simiar to 16 A GOST 7396 type C1, but for example in Sweden older 4.8 mm sockets are usually marked 10 A or 10 / 16 A stating that at the time no more than 10 A were allowed). The latter accept CEE 7/5 and CEE 7/4 plugs in addition to Europlugs, though without earth connection. Adaptors, trailing sockets, and power strips designed to accept only Europlugs with 4 mm pins may also have plastic barriers in place to prevent CEE 7/17, Schuko or French plugs from entering. The earthed CEE 7/5 and CEE 7/4 sockets were specifically designed to not allow insertion of an unearthed round plug from older appliances that were earthed via other means, but the CEE 7/17 plug has notches to allow it be used in those sockets by devices not requiring an earth. Round unearthed sockets and plugs are for class 0 insulation and are not a kind of Europlug. Europlugs are for class II insulation and designed specifically to plug in CEE 7/5 and CEE 7/4 sockets (and also round unearthed sockets, and some other sockets).

Danish Section 107-2-D1 earthed(Type K)

This Danish standard plug is described in the Danish Plug Equipment Section 107-2-D1 Standard sheet (SRAF1962/DB 16/87 DN10A-R). Unlike the French CEE 7/5 plug, the earthing pin is on the plug, not in the socket. The Danish socket need not be recessed to protect the earthing pin. The Danish standard provides for sockets to have child-resistant shutters.

The Danish socket will also accept the CEE 7/16 Europlug or CEE 7/17 Schuko-French hybrid plug. CEE 7/4 (Schuko), CEE 7/7 (Schuko-French hybrid), and earthed CEE 7/5 French plugs will also fit into the socket but should not be used for appliances that need earth contact. The current rating on both plugs is 13 A.

A variation (standard DK 2-5a) of the Danish plug is for use only on surge protected computer sockets. It fits into the corresponding computer socket and the normal socket, but normal plugs deliberately don't fit into the special computer socket. The plug is often used in companies, but rarely in private homes.

There is a variation for hospital equipment with a rectangular left pin, which is used for life support equipment.

Traditionally all Danish sockets were equipped with a switch to prevent touching live pins when connecting/disconnecting the plug. Today, sockets without switch are allowed, but then it is a requirement that the sockets have a cavity to prevent touching the live pins. The shape of the plugs generally makes it difficult to touch the pins when connecting/disconnecting.

Since the early 1990s earthed sockets have been required in all new electric installations in Denmark. Older sockets need not be earthed, but all sockets, including old installations, must be protected by earth-fault interrupters (HFI or HPFI in Danish) by 1 July 2008.

As of 1 July 2008, wall sockets for French 2-pin, female earth CEE 7/5 are permitted for installations in Denmark.[40] This was done because no electrical equipment sold to private users is equipped with a Danish plug.

Sockets for the Schuko were not permitted until 15 November 2011. It could also result in a bad connection of the pins, with resultant risk of overheating and fire. Many international travel adapter sets sold outside Denmark match CEE 7/16 (Europlug) and CEE 7/7 (Schuko-French hybrid) plugs which can readily be used in Denmark.

Denmark has allowed CEE 7/4 "Schuko" sockets from 15 November 2011.[41]

Italy (Type L)

Italian earthed plugs and sockets are defined by the standard CEI 23-50 which superseded CEI 23-16, this includes two models rated at 10 A and 16 A that differ in contact diameter and spacing (see below for details). Both are symmetrical, allowing the line and neutral contacts to be inserted in either direction. This plug is also commonly used in Chile.

The 10 A plug has pins which are 4 mm in diameter, the centres spaced 19 mm apart. The 10 A socket can accept Europlugs. The 16 A plug has pins which are 5 mm in diameter, the centres spaced 26 mm apart. The 16 A socket used to be referred to as per la forza motrice[42] (for electromotive force, see above) or sometimes (inappropriately) industriale (industrial). Large appliances are usually sold with Schuko plugs, so 16 A non-rewirable plugs are usually used only in adapters and power cords. Those appliances are always earthed, so unearthed 16 A plugs are now very uncommon, and only a few brands still sell them in rewirable version.[citation needed]

The double standard was initially adopted because in Italy, up to the second half of the 20th century, electricity used for lamps and that used for all other purposes was sold at different tariffs, charged with different taxes, accounted with separated electricity meters, and sent on different wire lines that ended with different sockets.[43] Even though the two electric lines (and respective tariffs) were gradually unified beginning in the 1960s (the official, but purely theoretical date was the summer of 1974[44]) many houses kept twin wires and twin electricity meters for years thereafter (in some zones of Lazio the 127 V network was provided for lighting until 1999). The two gauges for plugs and sockets thus became a de facto standard which is now standardized under CEI 23-50. Older installations often have sockets that are limited to either the 10 A or the 16 A style plug, requiring the use of an adapter if the other gauge needs to be connected. Numerous cross adapters were used.

Unearthed Europlugs are also in common use; they are standardized in Italy under CEI 23-5 and fit most of the appliances with low current requirement and double insulation.

Appliances with CEE 7/7 Schuko-French plugs are often sold in Italy too; however most sockets will not accept them since the pins of the CEE 7/7 Schuko-French plugs are thicker than the Italian ones. Adapters are standardized in Italy under CEI 23-57, they are commonly used to connect CEE 7/7 plugs to CEI 23-16/VII sockets, but they cannot exceed 1500 watts and could make an unsafe connection in some cases.

The current Italian standards provide for sockets to have child-resistant shutters (“Sicury” patent [45])

Italian multiple standard sockets

In modern installations in Italy (and in other countries where Type L plugs are used) it is usual to find sockets that can accept more than one standard.

The simpler type has a central round hole and two figure-8 shaped holes above and below. This design allows the connection of both 10 A and 16 A plugs and the Europlug. The advantage of this socket style is its small, compact face. VIMAR brand claims to have patented this socket first in 1975[46] with their Bpresa™ model; however soon other brands started selling similar products, mostly naming them with the generic term presa bipasso (twin-gauge socket) that is now of common use.

A second, quite common type looks like a Schuko socket, but adds a central earthing hole. This design can accept CEE 7/4 (German), CEE 7/7 (German/French), and Italian 10 A plugs. Some of these sockets may also have figure-8 shaped holes to accept Italian 16 A plugs as well. Its drawback is that it is twice as large as a normal Italian socket and the price is higher; for those reasons Schuko and bipasso-Schuko socket are rarely installed in Italy.[citation needed]

Other types may push compatibility even further. The VIMAR-brand universale (all purpose) socket, for example, accepts CEE 7/4 (German), CEE 7/7 (German/French), Italian 10 and 16 A plugs, and also NEMA 1-15 (USA/Japan) plugs (older versions also had extra holes to accept UK shaver plugs).

Soviet standard GOST 7396 C 1 unearthed

This Soviet plug, still widely used in modern Russia, has pin dimensions and spacing equal to the Europlug, but lacks the insulation sleeves. Unlike the Europlug, it is rated 6 A. It has a round body like the French CEE 7/5 or flat body with a round base like CEE 7/17. The round base has no notches. The pins are parallel and do not converge. The body is made of fire resistant thermoset plastic. The corresponding 6 A socket accepts the Europlug, but not others as the 4.5 holes are too small to accept the 4.8 mm pins of CEE 7/4, CEE 7/5 or CEE 7/7 plugs.

There were also moulded rubber plugs available for devices up to 16 A similar to CEE 7/17, but with a round base without any notches. They could be altered to fit a CEE 7/5 or CEE 7/4 socket by cutting notches with a sharp knife.

-

Soviet grip plug, 6 A 250 V AC, thermoset plastic

-

Soviet round plug, 6 A 250 V AC, thermoset plastic, half height

-

Moulded rubber soviet plugs cut with knife in attempt to be similar to CEE 7/16 (left) and CEE 7/17 (right). Originally the plugs had a round base.

-

Soviet shaver power cord. The plug is similar to CEE7/16, but has different configuration. Thermoplastic plug is rated 6 A and 250 V.

Swiss SEV 1011 (Type J)

Switzerland has its own standard which is described in SEV 1011 (ASE1011/1959 SW10A-R).[47] This plug is similar to the Europlug (CEE 7/16), except that it has an offset earth pin and the pin shanks are not necessarily insulated (the pins of most modern appliances are), so plugs partially inserted into non-recessed sockets present a shock hazard. However, since 1 January 2013, only partially insulated plugs of type CEE 7/16 (Europlug, unearthed, SEV 1011 type 11) and of type J plugs (SEV 1011 type 12) are allowed to be imported and distributed[48] to reduce the risk of electric shocks. Sockets used in kitchens, bathrooms and other wet areas are recessed, while those used elsewhere are not (after 2016, only recessed sockets are allowed to be installed in any setting, minimizing the risk of electric shocks). Some plugs and adaptors have a tapered form and can be used in either environment, while others will fit only the non-recessed sockets. Swiss sockets accept Swiss plugs or Europlugs (CEE 7/16). There is also a non-earthed two-pin variant with the same pin shape, size, and spacing as the SEV 1011's line and neutral pins, but with a more flattened hexagonal form. It fits into Swiss sockets and CEE 7/16 sockets, and is rated 10 A.

The SEV 1011 earth pin is offset by 5 mm[49] from the centre line of the line and neutral pins.

The system is modular and allows variants with five pins for three phases and square pins for 16 A (and the combination of both—see reference). Above 16 A, equipment must either be hardwired to the electrical supply system with appropriate branch circuit protection, or connected to the mains with an appropriate high power industrial connector.

IEC 60906-1 (Type N)

In 1986, the International Electrotechnical Commission published IEC 60906-1, a specification for a plug and socket that look similar, but are not identical, to the Swiss plug and socket. This standard was intended to one day become common for all of Europe and other regions with 230 V mains, but the effort to adopt it as a European Union standard was put on hold in the mid-1990s.[50]

The plug and socket are rated 16 A 250 V a.c. and are intended for use only on systems having nominal voltages between 200 V and 250 V a.c. The plug pins are 4.0 mm in diameter, line and neutral are on centres 19 mm apart. The earth pin is offset 3.0 mm. The line pin is on the left when looking at a receptacle with the earth pin offset down. Shutters over the line and neutral pins are mandatory.

The only country to have officially adopted the standard is South Africa as SANS 164-2.[51][52]

Brazil adopted a non-compliant version of IEC 60906-1 as the national standard under specification NBR 14136.[53] The NBR 14136 standard has two versions, neither of which has pin dimensions or ratings complying to IEC 60906-1. Use at 125 V is permitted by NBR 14136, which is against the intention of IEC 60906-1.

China CPCS-CCC (Type I)

The standard for Chinese plugs and sockets is set out in GB 2099.1‐2008 and GB 1002‐2008. As part of China's commitment for entry into the WTO, the new CPCS (Compulsory Product Certification System) has been introduced, and compliant Chinese plugs have been awarded the CCC Mark by this system. The plug is three wire, earthed, rated at 10 A, 250 V and used for Class 1 applications; a 16 A version also exists. The Australian plug fits, though the pins on the Chinese plug are thinner and 1 mm (0.039 in) longer. China also uses American/Japanese NEMA 1‐15 sockets and plugs for Class-II appliances. The voltage at a Chinese socket of any type is 220.

Israel SI32 (Type H)

The plug defined in SI 32 (IS16A-R), is unique to Israel. There are two kinds: One with flat pins, and the other with round ones. The pre-1989 system has three flat pins to form a Y-shape. Line and neutral are spaced 19 mm (0.75 in) apart. The plug is rated at 16 A.

In 1989, the standard was revised to use three round 4.5 mm (0.177 in) pins in the same locations, allowing the socket to accept the Europlugs used in Europe and Israel for non-earthed appliances. Sockets made since 1989 accept both flat and round pins for compatibility with both old and new plugs. Pre-1989 sockets which accept only old-style plugs are very rare in Israel.

SI 32 plugs have no sleeve insulation, so when an SI 32 plug is partially removed its prongs may still be connected to the socket—increasing the chance of electric shock.

This plug is also used in the areas controlled by the Palestinian Authority: the West Bank and the Gaza Strip.

North American and IEC 60906-2

Most of North America, and some of South America, use connectors standardized by the National Electrical Manufacturers Association. The devices are named using the format NEMA n-mmX, where n is an identifier for the configuration of pins and blades, mm is the maximum amperage, and X is either P (plug) or R (receptacle). For example, NEMA 5-15R is a configuration type 5 receptacle supporting 15 amps. "P" and "R" versions are designed to be mated. The above describes the standard NEMA connector. twist-locking variations exist for many of them, using a different pin configuration. The prefix "L" is added for the locking versions. For example, the locking equivalent of NEMA 5-15P is NEMA L5-15P

For some configurations, the arrangement of pins will differ slightly for the different amperage versions, to prevent accidental mating of devices with a higher current draw than the receptacle can support.

IEC 60906-2 uses NEMA 5-15.

A brief description of some common NEMA standards appears below. A more comprehensive list, with more detail, appears in the NEMA connector article.

NEMA 1-15 ungrounded (Type A)

NEMA-1 plugs are compatible with both NEMA-1 receptacles and NEMA-5 receptacles; NEMA-1 is ungrounded (no earth), while NEMA 5 is grounded. The plug has two parallel blades. Early versions were not polarized, but almost all plugs are polarized today via a taller neutral blade on the plug and corresponding plug on the receptacle.

Ungrounded NEMA-1 outlets are not permitted in new building construction in the United States and Canada, but can still be commonly found in older construction. Allowed replacement of NEMA-1 receptacles varies by local code.

NEMA 5-15 grounded (Type B)

The NEMA 5-15 plug has two flat parallel blades like NEMA 1-15, but also adds a ground (earth) pin.[54] It is rated 15 A at 125 volts. The ground pin is longer than the line and neutral blades, so the device is grounded before the power is connected. Both current-carrying blades on grounding plugs are normally narrow, since the ground pin enforces polarity. NEMA 1-15 plugs are also compatible with NEMA 5-15 sockets.

The 5-15 socket is standard in Canada, the United States, Mexico and Panama. It is also used in Central America, the Caribbean, northern South America (Colombia, Ecuador, Venezuela and, as a legacy, parts of Brazil), Japan, Taiwan, the Philippines and Saudi Arabia. This socket is recommended in IEC standard 60906-2 for 120 volt 60 Hz installations. Looking directly at a NEMA 5-15 socket with the earth at the bottom, the neutral slot is on the left, and the line slot is on the right. Sockets may be installed in any orientation.

In 46 of the 50 United States[55] and all of Canada, tamper-resistant sockets are now required in new residential construction. These prevent contact by objects like keys or paper clips inserted into the socket.[56]

In stage lighting, this connector is sometimes known as PBG for Parallel Blade with Ground (earth), Edison or Hubbell, the name of a common manufacturer.[57]

NEMA 5-20

As NEMA 5 amperages increase, changes are made to the plug's neutral so that it will not fit into lower amperage receptacles. Some higher amp receptacles are designed to accept multiple shapes for the neutral blade, so that both higher and lower draw devices are compatible with it.

The NEMA 5-20 AP variant has a "horizontal" neutral blade (in a plane that would intersect the hot blade). The receptacle has a T-slot for the neutral blade which accepts either 15 A parallel-blade plugs or 20 A plugs.

NEMA 5-30 and 5-50 are rare; L5-30 and L5-50 twistlock is more common. The non-locking versions are physically incompatible with 5-15 and 5-20, as the hot/neutral blades are farther apart.

NEMA 14-30

A 30 A, 3 wire single-phase earthing socket is often used for electric clothes dryers. 240 volts from the split phase system is used for the heating elements, and the motor and controls run on 120 volts. These plugs have blades that are rather larger than NEMA 5-20, are more widely spaced, and are angled so as to prevent using the wrong plug in the wrong circuit.

NEMA 14-50

A 50 A 3 wire single-phase earthing socket is usually installed in kitchens and used for electric cooking ranges and ovens. As for dryers, lighting and motors run on 120 V and the main heating element is connected for 240 V. Many plug-in electric cars use this type of socket for recharging in the owner's garage.

JIS C 8303, Class II unearthed

The Japanese plug and socket appear physically identical to NEMA 1-15. The Japanese system incorporates stricter dimensional requirements for the plug housing, different marking requirements, and mandatory testing and approval by METI or JIS.[58]

Older Japanese sockets and multi-plug adapters are unpolarized—the slots in the sockets are the same size—and will accept only unpolarized plugs. Japanese plugs generally fit into most North American sockets without modification, but polarized North American plugs may require adapters or replacement non-polarized plugs to connect to older Japanese sockets. In Japan the voltage is 100 V, and the frequency is 50 Hz (East Japan) or 60 Hz (West Japan). Therefore, some North American devices which can be physically plugged into Japanese sockets may not function properly.

JIS C 8303, Class I earthed

Japan also uses an unearthed plug similar to the North American NEMA 5-15.[58] However, it is less common than its NEMA 1-15 equivalent. Since 2005, new Japanese homes are required to have class I earthed sockets for connecting domestic appliances. This rule does not apply for sockets not intended to be used for domestic appliances, but it is strongly advised to have class I sockets throughout the home.[59]

Thai 3 pin plug TIS 166-2549 (2006)

Thai Industrial Standard (TIS) 166-2547 and its subsequent update TIS 166-2549 stipulated a modification of the IEC 60906-1 plug, replacing prior standards which were based on NEMA 1-15 and 5-15, as Thailand uses 220 V electricity. The plug has two round power pins 4.8 mm in diameter and 19 mm in length, insulated for 10 mm and spaced 19 mm apart, with an earthing pin of the same diameter and 21.4 mm in length, located 11.89 mm from the line connecting the two power pins. It was designed to provide compatibility with prior hybrid three-pin sockets, which accept NEMA 1-15, NEMA 5-15 and Europlugs, all of which have been variably used in Thailand. The hybrid socket is also defined in TIS 166-2547, in addition to a plain three-round-pin socket, with plans to replace the former and phase out support for NEMA-compatible plugs. Sockets are polarised (as in NEMA 5-15).[60] The plug is similar to, but not interchangeable with, the Israeli SI32 plug.

Comparison of standard types

| IEC World Plugs Type1 |

Standard | Power rating |

Earthed | Polarised | Fused | Insulated pins |

Europlug Compatible |

|---|---|---|---|---|---|---|---|

| A | NEMA 1-15 unpolarised | 15 A/125 V | No | No | No | No | No |

| NEMA 1-15 polarised | 15 A/125 V | No | Yes | No | No | No | |

| JIS C 8303, Class II | 15 A/100 V | No | No | No | No | No | |

| B | NEMA 5-15 | 15 A/125 V | Yes* | Yes | No | No | No |

| NEMA 5-20 | 20 A/125 V | Yes* | Yes | No | No | No | |

| JIS C 8303, Class I | 15 A/100 V | Yes* | Yes | No | No | No | |

| C | CEE 7/16 (Europlug) | 2.5 A/250 V | No | No | No | Yes | Yes |

| - | CEE 7/17 | 16 A/250 V | No | No2 | No | No | Yes |

| - | GOST 7396 C 1 | 6 A/250 V 16 A/250 V |

No | No | No | No | Yes |

| - | BS 4573 | Socket 0.2 A/250 V Plug Unspecified7 |

No | No | No | Yes | No |

| D | BS 546 | 2 A/250 V 5 A/250 V 15 A/250 V 30 A/250 V |

Yes | Yes | Optional | Optional | No |

| E | CEE 7/5 ‡ | 16 A/250 V | Yes* | Yes4 | No | No† | Yes |

| F | CEE 7/4 Schuko ‡ | 16 A/250 V | Yes* | No | No | No† | Yes |

| G | BS 1363, IS 401 & 411, MS 589, SS 145 | 13 A/250 V | Yes | Yes | Yes | Yes | No |

| H | SI 32 | 16 A/250 V | Yes5 | Yes | No | No | Yes |

| - | TIS 166-2549 | 16 A/250 V | Yes | Yes | No | Yes | Yes |

| I | AS/NZS 3112 | 10 A/240 V 15 A/240 V 20 A/240 V 25 A/240 V 32 A/240 V |

Yes* | Yes | No | Yes | No |

| CPCS-CCC | 10 A/250 V | Yes | Yes | No | No | No | |

| IRAM 2073 | 10 A/250 V | Yes | Yes | No | No | No | |

| J | Swiss SEV 1011 | 10 A/250 V 16 A/250 V |

Yes* | Yes | Optional5 | Optional6 | Yes |

| K | Danish 107-2-D1 | 13 A/250 V | Yes* | Yes | No | No | Yes |

| L | CEI 23-16/VII | 10 A/250 V 16 A/250 V |

Yes* | No | No | Yes | Yes |

| M | South Africa SABS 164-1 | 16 A/250 V | Yes | Yes | Optional | Optional | No |

| N | Brazilian NBR 14136 (2 pin) | 10 A/250 V 20 A/250 V |

No | No | No | Yes | Yes |

| Brazilian NBR 14136 (3 pin) | 10 A/250 V 20 A/250 V |

Yes* | Yes | No | Yes | Yes | |

| South Africa SABS 164-2 (2 pin) | 16 A/250 V | No | No | No | Yes | Yes | |

| South Africa SABS 164-2 (3 pin) | 16 A/250 V | Yes* | Yes | No | Yes | Yes |

- * Compatible with unearthed plugs.

- † Deep-wall socket prevents human contact with pins.

- ‡ CEE 7/7 specifies an earthed hybrid plug that will fit into both the CEE 7/4 and CEE 7/5 sockets. CEE 7/17 specifies an unearthed hybrid plug that will fit into both the CEE 7/4 and CEE 7/5 sockets.

- 1 Type letters are from the International Electrotechnical Commission (IEC) Web site [61] that provides classification letters similar to a United States Department of Commerce publication [27] that sees widespread but not universal use to differentiate plug and socket types based on rough mechanical compatibility. Most common household plugs have an associated letter.

- 2 There are some CEE 7/17 plugs with special shape which are polarised when used with CEE 7/5 sockets (mechanically only).

- 3 Plug can only be inserted one way with French CEE 7/5, but lack of wiring convention means that the system is not polarized.

- 4 Newer sockets can accept unearthed Europlugs.

- 5 Fused type technically possible and existing, but rare and unusual

- 6 Import of plugs with non-partially-insulated pins no longer allowed after 2012

- 7 BS 4573 itself does not explicitly specify a current rating for a compliant plug, see BS 4573section of British and compatible standards.

Multi-standard sockets

Sockets that take a variety of plug types can be found in places where market size or local market conditions make a specific plug standard impractical to implement. Sockets may accept plugs to various European, Asian, North American, British or Australian standards, but not Indian or South African. Multi-standard sockets do not safeguard against devices being damaged by the wrong voltage. Users must know the voltage requirements of their appliances as well as the prevailing local voltage.

Note that in Multi-standard sockets the aperture size for NEMA plugs is often the same for both Line (Hot) and Neutral (see second picture), sometimes too small to allow the use of polarized NEMA 1 plugs, otherwise large enough to allow the use of such plugs in either orientation (a standard NEMA socket allows a polarized plug to be inserted only in the correct orientation). Note also that in a socket designed to accept both NEMA and BS 1363 plugs, the lower right contact (in the orientation shown in the picture) should be connected to the Line wire for BS 1363 plugs, but the Neutral wire for NEMA plugs, so safe wiring of these devices for universal use is not possible.

Some of these sockets have one or more earth holes to allow 3-pin plugs. On properly wired circuits, the earth contact will be connected to earth. However, they cannot provide earthing to all types of plugs, as is the case of Schuko (which requires recessed sockets containing side earthing contacts) and French plugs (which require an earthing pin projecting from the socket).

Those designed to accept British plugs have pin apertures which are larger than allowed by BS 1363, and are therefore not legal for UK or Irish use.[62]

Adaptors

Adaptors allow travellers to use portable devices with foreign sockets. Adaptors allow physical connection between plug and socket but do not change voltage or frequency. A voltage converter is required for electrical compatibility in countries with a different voltage than the device is designed for, if it is not designed for variable voltage input.

Obsolete types

Old Spanish sockets

Some older industrial buildings in Spain used sockets that took a plug rated for higher current and had two flat contacts and a round earth pin, somewhat similar in design to the ones found on American plugs but larger in size. The two flat contacts are spaced further apart than on an American plug. No domestic appliances were ever sold with these plugs.

The line and neutral measure 9 by 2 mm (0.354 by 0.079 in), and are 30 mm (1.181 in) apart. All three pins are 19 mm (0.748 in) long, and the earth pin is a cylinder of 4.8 mm (0.189 in) diameter.

Original American Hubbell plug and receptacle

An early American electrical plug and socket was invented by Harvey Hubbell and patented in 1904. Hubbell's first design was a socket which screwed into a lampholder (like the early lampholder plugs), but with a separable plug with pins or blade (U.S. patent 774,250). The 1906 Hubbell catalog shows this plug with a flush mounting socket for use in wall or floor. Other manufacturers adopted the Hubbell pattern, and by 1915 they were widespread.[63][64]

American 125 V, 15 A / 250 V, 10 A "Australian" style

A patent for this obsolete American plug and socket was filed in 1915 under US patent 1,179,728.[65] It predated the NEMA sockets and plugs. The plugs and sockets used in countries such as Argentina, Australia and China are based on this type.

Split current/voltage ratings

Many older North American sockets have two different current and voltage ratings, most commonly 10 A 250 V/15 A 125 V. This has to do with a peculiarity of the National Electrical Code from 1923 to the 1950s. Originally, sockets were rated at 10 A 250 V, because the NEC limited lighting circuits to 10 A. In 1923, the code changed to allow lighting circuits to be fused at 15 A, but the previous 10 A rule still applied to circuits over 125 V.[66] The higher voltages were rarely used for lighting and appliances. Most sockets with this rating are of the "T-slot" type.

US perpendicular socket

Another obsolete socket, made by Bryant, 125 V 15 A and 250 V 10 A rating. A NEMA 5‐20 125 V 20 A or 6‐15 250 V 15 A plug with a missing earth pin would fit this socket, but a NEMA 2‐20 plug is slightly too big to fit.

The upper slots as seen in the illustration connect to silver-colored wiring screws on the upper side, and the lower slots connect to brass-coloured wiring screws on the lower side.

In Australia, the same or similar T-configuration sockets are used for DC power sockets, such as in stand-alone power systems (SAPS), on boats and in police vehicles. Polarity is inconsistent.

In the former Soviet Union this socket was and still is commonly used for wiring in places where the voltage is lowered for safety purposes, like in schools, filling stations or in wet areas, and is rated 42 V 10 A AC. Such an unusual connection is intended specifically to make the connection of standard higher-voltage equipment impossible.

US combination duplex socket

The parallel and tandem socket accepts normal parallel NEMA 1‐15 plugs and also tandem NEMA 2‐15 plugs. Both pair of socket are fed internally by the same supply.

A more recent and fairly common version of this type is the T-slot socket, in which the locations of the tandem and the parallel slots were combined to create T-shaped slots. This version also accepts normal parallel NEMA 1‐15 plugs and also tandem NEMA 2‐15 plugs. Incidentally, a NEMA 5‐20 (125 V, 20 A), a NEMA 6-15 (250 V, 15 A) or 6‐20 (250 V, 20 A) plug with a missing earth pin would fit this socket. This type has been unavailable in retail shops since the 1960s but still available from the manufacturer Leviton (model 5000-I) not for new installation for replacement only.

UK Obsolete types

Lampholder plug

A lampholder plug fits into the bayonet cap or Edison screw socket of a lampholder in place of a light bulb and enables an electrical appliance to be powered from a wall or ceiling light fitting. As mentioned in Early History above, they were first introduced in the late 1800s and in use to the 1960s in situations where wall sockets were scarce and sometimes non-existent in some rooms (bathrooms, cellars, attics, etc.). Also, as in some countries (such as Italy) electricity was supplied on a "split tariff" basis with electricity for lighting being charged at a lower rate than that for other purposes, lampholder plugs enabled the consumers to reduce their electricity costs and were thus in broad use.

Lampholder plugs were and are rarely fused.

In the UK, lighting circuits are protected with a 5 A or 6 A fuse or circuit breaker.[67] Wiring regulations in the UK and some other countries no longer approve lampholder plugs because of the risks of overheating and fire.

Edison screw lampholder adaptors (for NEMA 1-15 plugs) are still easily found and commonly used in the Americas.

Old Greek sockets

Called "Tripoliki" (τριπολική, meaning "three-pole"), the standard had 3 round pins, similarly to the Swiss SEV 1011 and to the post-1989 Israeli/Thai type, virtually abandoned by 1995. Previous to the large-scale adoption of Schuko plugs, this was the only way to use an earthed appliance.

Unusual types

NEMA 2‐15 and 2‐20

These unearthed plugs with two flat parallel blades are intended for use on 240 volt circuits. The 2‐15 has coplanar current blades, and is used for 240 V service at 15 A, while the 2‐20 has the blades at 90° relative to each other (one vertical, one horizontal) and is used for 240 V service at 20 A. NEMA 2 plugs and sockets are rare because they are unearthed and so, no longer permitted for new installations. They have no neutral. In some cases these plugs can be inserted into incorrect-voltage sockets. Prior to the adoption of the NEMA standard, a plug nearly identical to the 2‐20 was used for 120 V at 20 A. That obsolete plug would fit into 5‐20 and 6‐20 sockets, which supply different voltages, but will not fit a NEMA 2‐20 socket.

Soviet adaptor plugs

Some appliances sold in the Soviet Union had a flat unearthed plug with an additional pass-through socket on the top, allowing stacked arrangement of plugs. This design was very helpful (for the usual Soviet apartment of the 1960s had very few sockets), but somewhat unsafe, as the brass cylinders of the secondary socket were uncovered at the ends (to unscrew them easily), recessed only for 3 mm and provided bad contact because they relied on the secondary plug's bisected expanding pins. The pins of the secondary plug (without insulation sleeves) could not be inserted into the cylinders completely, and were accessible through a 5 mm gap between the primary and secondary plugs.

UK Walsall Gauge plug

Unlike the standard BS 1363 plugs found in the UK, the earth pin is on a horizontal axis and the line and neutral pins on a vertical axis. This style of plug/socket was used by university laboratories (from batteries) and the BBC, and is still in use on parts of the London Underground for 110 V AC voltage supply.[68]

They were also used in the Ministry of Defence Main Building on circuits powered from the standby generators to stop staff from plugging in unauthorised devices, e.g. kettles.

Italian Bticino brand Magic security connector

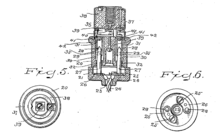

This style of connector, produced by Italian manufacturer Bticino, appeared in the 1960s and was intended as an alternative to the Europlug or CEI 23-16/VII connectors then in use.[69] The socket is an almost rectangular socket, with one or more lateral key pins and indentations to prevent inverting the polarised plug, or connecting plugs and sockets with different current ratings. At least four models were produced: three single-phase general purpose connectors rated respectively 10 A, 16 A and 20 A; plus a three-phase industrial connector rated 10 A; all of them have different key-pin positioning so plugs and sockets cannot be mismatched.[70] The socket is closed by a safety lid (bearing the word ‘’Magic’’ on it) which can be opened only with an even pressure on its surface, thus preventing the insertion of objects (except the plug itself) inside the socket. The contacts are blades positioned on both sides of the plug; the plug is energized only when it is inserted fully into the socket.

The obvious drawback of the system is that it is not compatible with Europlugs. As household appliances were never sold fitted with these security plugs and the use of adapters would defeat all of the newly introduced safety features, once this system is adopted all standard plugs must be cut off and replaced with the appropriate security connector. However, the Magic security system had some success at first because its enhanced safety features appealed to customers; standard connectors of the day were considered not safe enough.[69] The decline of the system occurred when safety lids similar to the Magic type were developed (VIMAR Sicury[71]) and then applied to standard sockets by third brands and by Bticino itself.

In Italy, the system was never definitively abandoned and, though rarely seen today, is still marked as available in Bticino’s products catalogue,[72] (except for the three-phase version, that is no longer in production from July 2011)

In Chile, 10 A Magic connectors are commonly used for computer/laboratory power networks, as well as for communications or data equipment. This allows delicate electronics equipment to be connected to an independent circuit breaker, usually including a surge protector or an uninterruptible power supply backup. The different style of plug makes it more difficult for office workers to connect computer equipment to a standard unprotected power line, or to overload the UPS by connecting other office appliances.

In Iceland, Magic plugs were widely used in homes and businesses alongside Europlug and Schuko installations. Their installation in new homes was still quite common even in the late 1980s.

Single phase electric stove plugs and sockets

The plugs and sockets used to power electric stoves from a single-phase line have to be rated for greater current values than ones for three-phase system because all the power has to be transferred through a single line. Electric stoves are often hardwired to the electrical supply system, connected to the mains with an appropriate high power industrial connector or with non-standard high power proprietary domestic connector (as some countries do not have wiring regulations for single-phase electric stoves). In Russia an electric stove can often be seen connected with a 25 to 32 A connector.

Industrial and multiphase

Plug and socket systems intended for high current, high voltage or polyphase industrial equipment, as well as additional contacts and larger contacts, may also include features to improve the security and safety of use. For example, a high-power plug may include a locking ring or twist-lock feature to prevent accidental disconnection in use. A socket may include a mechanical interlock that prevents insertion or removal of a plug unless the local safety disconnecting switch is open. Plugs may include special measures to contain an arc generated during disconnection. Plugs used for equipment in wet locations (such as mines) may include small supervisory contacts that check the integrity of the earthing conductor.

See also

- AC adapter

- DC connector

- IEC 60309 high-power industrial and polyphase connectors

- Mains electricity by country lists voltage, frequency, and connector types for over 200 countries

- Plug load

- Polyphase system

- Stage pin connector

References

- ^ IEC/TR 60083, Plugs and socket-outlets for domestic and similar general use standardized in member countries of IEC, CH: International Electrotechnical Commission, 2009

- ^ [1], Snort For Dummies, Charlie Scott et al, John Wiley & Sons, 2004, p.227 (retrieved 1 March 2013 from Google Books)

- ^ [2], Physics for AQA, Patrick Fullick, Heinemann, 2001, p.16 (retrieved 1 March 2013 from Google Books)

- ^ [3], Trevor Linsley, Routledge, 2008, p.37 (retrieved 2 March 2013 from Google Books)

- ^ [4], IEC/TR 60083 Ed. 6.0, IEC, 2009 (retrieved 1 March 2013 from Techstreet)

- ^ Collins (2006), "Power Point", Essential English Dictionary (2nd ed.), The Free Dictionary

- ^ [5], Building Surveys and Reports, James Douglas, John Wiley & Sons, 2010, p.254 (retrieved 1 March 2013 from Google Books)

- ^ [6], Computer Networking First-Step, Wendell Odom, Cisco Press, 2004, p.38 (retrieved 1 March 2013 from Google Books)

- ^ [7], Building Technology: Mechanical and Electrical Systems, Benjamin Stein, John Wiley & Sons, 1997, p.723 (retrieved 1 March 2013 from Google Books)

- ^ [8], Tamper Resistant Receptacles, Electrical Safety Foundation International, 2009, (retrieved 1 March 2013 from ESFI)

- ^ Smart Guide Wiring: step-by-step projects, Fran J. Donegan, Creative Homeowner Press, 2004, p.74 (retrieved 2 February 2012 from Google Books)

- ^ [9]Electrical Inspection Manual, 2011 Edition], Noel Williams & Jeffrey S Sargent, Jones & Bartlett Publishers, 2012, p.249 (retrieved 3 March 2013 from Google Books)

- ^ [10]17th Edition IEE Wiring Regulations: Explained and Illustrated], Brian Scaddan, Routledge, 2011, p.18 (retrieved 6 March 2013 from Google Books)

- ^ [11]Electrical Product Safety], Dave Holland, M.B, Jimmy Tzimenakis, Newnes, 1999, p.58 (retrieved 3 March 2013 from Google Books)

- ^ "More Small Things Forgotten: Domestic Electrical Plugs and Receptacles, 1881-1931", Fred E. H. Schroeder, Technology and Culture Vol. 27, No. 3 (Jul., 1986), pp. 525-543, Published by: Society for the History of Technology

- ^ "The History of Electric Wiring" (1957), London: Macdonald.

- ^ "History". Hubbell. 2009. Retrieved 20 March 2010.

- ^ Witte (1922). "The Automobile Storage Battery Its Care and Repair". Powerstream. Archived from the original on 24 August 2007. Retrieved 14 September 2007.

{{cite web}}: Unknown parameter|deadurl=ignored (|url-status=suggested) (help) - ^ Crist (2005). "Sockets" (tutorial). Mosaic shades. Retrieved 14 September 2007.

- ^ "SMALL SWITCHES, etc., and their CIRCUITS" (1911), MAYCOCK, W. Perren, London: S. Rentall & Co.

- ^ [12], Electric cooking, heating, cleaning, etc: being a manual of electricity in the service of the home, Maud Lucas Lancaster, Constable & Company, Ltd., 1914, p.312 (retrieved 13 March 2013 from Google Books)

- ^ U.S. patent 1,179,728

- ^ German patent number DE 370538

- ^ U.S. patent 1,672,067

- ^ "History, retrieved 2012 Dec 19". Iec.ch. Retrieved 12 March 2013.

- ^ "IEC Webstore preview Retrieved 2011 October 19" (PDF). Retrieved 12 March 2013.

- ^ a b "Electric Current Abroad" (PDF). US Department of Commerce, International Trade Administration. 2002.

- ^ ftp://ftp.cencenelec.eu/CENELEC/TCs/61/PlugsSockets.pdf Plugs and socket types in each CENELEC country, Retrieved 15 February 2012

- ^ AS/NZS 3112:2004, Approval and test specification — Plugs and socket-outlets, Standards Australia and Standards New Zealand

- ^ "Australian Mains Plug Variants—AS/NZS 3112". Access Communications. 19 April 2007.

- ^ "Mains Plugs with Insulated Pins. Australian Standards AS/NZS3112:2000 & AS/NZS3112:2004 refer [sic]". Access Communications. 19 April 2007.

- ^ NBR 14136:2002 – Plugues e tomadas para uso doméstico e análogo – Padronização (in Portuguese), BR: ABNT, 2002

{{citation}}: Unknown parameter|trans_title=ignored (|trans-title=suggested) (help) - ^ "Norma ABNT NBR 14136:2002" (in Portuguese). BR: Projeto de redes.

- ^ a b World Plugs Retrieved on 2014-01-01.

- ^ BS 1363 (1995), BS 1363:1995 "13 A plugs, socket-outlets, adaptors and connection units , British Standards Institute.

- ^ BS 4573 (1970), British Standard Specification for two-pin reversible plugs and shaver socket-outlets, British Standards Institution.

- ^ ГОСТ 7396.1-89 (PDF) (in Russian), RU: Elec

- ^ Danish Safety Technology Authority

- ^ Typical example of BS 4573 compliant socket that accepts europlug (and Australian) http://www.tlc-direct.co.uk/Technical/DataSheets/MK/K700.pdf

- ^ 5. udgave af Stærkstrømsbekendtgørelsen afsnit 107-2-D1 "Stikpropper og stikkontakter for danske systemer" (in Danish), DK: Sik

- ^ BEK nr 1041 af 10/11/2011: Bekendtgørelse om stærkstrømsbekendtgørelsen, afsnit 6C, særlige krav til anvendelse af stikpropper og stikkontakter i installationer (in Danish), DK: Retsinformation

- ^ De Cesco G.: Acqua Luce Gas. Manuali pratici del far da sé. I Jolly bricolage. Fratelli Fabbri Editori, Milano, 1975. PP 70–71.

- ^ De Cesco G.: Acqua Luce Gas. Manuali pratici del far da sé. I Jolly bricolage. Fratelli Fabbri Editori, Milano, 1975. PP 56–57.

- ^ De Cesco G.: Acqua Luce Gas. Manuali pratici del far da sé. I Jolly bricolage. Fratelli Fabbri Editori, Milano, 1975. P 93.

- ^ "Bestreben Nach Sicherheit | Vimar". Vimar.de. Retrieved 12 March 2013.

- ^ La ricerca della sicurezza. Ma la ricerca continua (in Italian), EU: Vimar, retrieved 22 January 2009

- ^ Reference overview from the Swiss Federal Strong Current Inspectorate (Info from the Swiss Federal Administration)

- ^ New standard for plugs in Switzerland starting from 2013 (PDF, German/English)

- ^ "WA-11A Travel Plug Adapter for Switzerland". Adaptelec.

- ^ "International standardization of electrical plugs and socket-outlets for domestic use". CH: IEC.

- ^ "When Less is More..." ZA: Crab tree.

- ^ "SANS 164 standards: a working group perspective" (PDF). ZA: EE publishers.

- ^ NBR 14136:2002 – Plugues e tomadas para uso doméstico e análogo – Padronização (in Portuguese), BR: ABNT, 2002

{{citation}}: Unknown parameter|trans_title=ignored (|trans-title=suggested) (help) - ^ WD6, Dimensional requirements for plugs and receptacles (standard), USA: NEMA

- ^ Tamper-Resistant Receptacles — A Successful Adoption (PDF), retrieved 19 November 2013

- ^ Child outlet safety, archived from the original on 22 January 2009, retrieved 21 January 2009

{{citation}}: Unknown parameter|deadurl=ignored (|url-status=suggested) (help) - ^ Drew Campbell Technical Film and Tv for Nontechnical People, Skyhorse Publishing Inc., 2002 ISBN 1581159986 Chapter 9

- ^ a b JIS C 8303-1993, Plugs and Receptacles for Domestic and Similar General Use, Japanese Standards Association, 1993

- ^ 内線規程 改訂のポイントの解説ページ Template:Ja-icon

- ^ Thai Industrial Standard 166-2547: Plugs and socket-outlets for household and similar purposes: plugs and socket-outlets with rated voltage not exceeding 250 V (PDF) (in Thai). TH: Thai Industrial Standards Institute. ISBN 974-9815-94-7. Retrieved 23 November 2011.

- ^ "World Plugs, retrieved 2012 Dec 19". Iec.ch. Retrieved 12 March 2013.

- ^ [BS1363-2:1995+A4:2012, cl. 13.9

- ^ "History". Hubbell. 2009. Retrieved 20 March 2010.

- ^ Crist (2005). "Sockets" (tutorial). Mosaic shades. Retrieved 14 September 2007.

- ^ United States Patent and Trademark Office: US patent 1,179,728

- ^ Terrell Croft, Wiring for Light and Power, McGraw-Hill, 1924, pp. 198–99.

- ^ "Miniature Circuit Breakers" (PDF). UK: MK Electric. p. 4. Retrieved 22 April 2010.

- ^ Walsall Gauge in use at London Underground

- ^ a b De Cesco G.: Acqua Luce Gas. Manuali pratici del far da sé. I Jolly bricolage. Fratelli Fabbri Editori, Milano, 1975. P 73.

- ^ De Cesco G.: Acqua Luce Gas. Manuali pratici del far da sé. I Jolly bricolage. Fratelli Fabbri Editori, Milano, 1975. P 75.