2-Ethylanthraquinone: Difference between revisions

m →Uses: WP:CHECKWIKI error fixes using AWB (12068) |

|||

| Line 50: | Line 50: | ||

[[Hydrogen peroxide]] is produced industrially by the [[anthraquinone process]] which involves using 2-alkyl-9,10-anthraquinones for hydrogenation. Many derivatives of anthraquinone are used but 2-ethylanthraquinone is common because of its high selectivity. The hydrogenation of the unsubsituted ring can reach 90% selectivity by using 2-ethylanthraquinone. Hydrogenation follows the Riedl-Pfleiderer, or [[autoxidation]], process: |

[[Hydrogen peroxide]] is produced industrially by the [[anthraquinone process]] which involves using 2-alkyl-9,10-anthraquinones for hydrogenation. Many derivatives of anthraquinone are used but 2-ethylanthraquinone is common because of its high selectivity. The hydrogenation of the unsubsituted ring can reach 90% selectivity by using 2-ethylanthraquinone. Hydrogenation follows the Riedl-Pfleiderer, or [[autoxidation]], process: |

||

[[File:Riedl-Pfleiderer process.svg|left|400px|The Riedl-Pfleiderer process.]] |

[[File:Riedl-Pfleiderer process.svg|left|400px|The Riedl-Pfleiderer process.]]{{clear|left}} |

||

The [[hydrogenation]] of [[2-ethylanthraquinone]] is catalyzed by [[palladium]]. Hydrogenation produces both 2-ethylanthrahydroquinone and tetrahydroanthraquinone. The tetrahydro derivative of 2-alkylanthraquinone is easily hyrdrogenated but is more difficult to oxidize. The formation of the tetrahyrdo derivative can be suppressed through the selection of catalysts, solvents, and reaction conditions. Some suggested solvent mixtures are polyalkylated benzenes and alkyl phosphates or tetraalkyl ureas, trimethylbenzenes and alkylcyclohexanol esters, and methylnaphthalene and nonyl alcohols. |

The [[hydrogenation]] of [[2-ethylanthraquinone]] is catalyzed by [[palladium]]. Hydrogenation produces both 2-ethylanthrahydroquinone and tetrahydroanthraquinone. The tetrahydro derivative of 2-alkylanthraquinone is easily hyrdrogenated but is more difficult to oxidize. The formation of the tetrahyrdo derivative can be suppressed through the selection of catalysts, solvents, and reaction conditions. Some suggested solvent mixtures are polyalkylated benzenes and alkyl phosphates or tetraalkyl ureas, trimethylbenzenes and alkylcyclohexanol esters, and methylnaphthalene and nonyl alcohols. |

||

Revision as of 21:46, 10 August 2016

| |

| |

| Names | |

|---|---|

| Other names

2-Ethyl-9,10-anthracenedione

| |

| Identifiers | |

3D model (JSmol)

|

|

| ChEMBL | |

| ChemSpider | |

| ECHA InfoCard | 100.001.396 |

| EC Number |

|

CompTox Dashboard (EPA)

|

|

| |

| |

| Properties | |

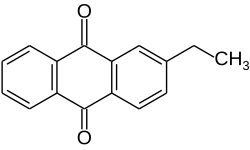

| C16H12O2 | |

| Molar mass | 236.27 g/mol |

| Appearance | white to yellowish crystals or powder |

| Density | 1.231g/cm3 |

| Melting point | 105 °C (221 °F; 378 K) |

| Boiling point | 415.4 @ 760mmHg |

| Hazards | |

| Flash point | 155.4 °C (311.7 °F; 428.5 K) |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

| |

2-Ethylanthraquinone is an organic compound that is a derivative of anthraquinone. It is pale yellow solid is used in the industrial production of hydrogen peroxide (H2O2).[1][2]

Production

2-Ethylanthraquinone is prepared from the reaction of phthalic anhydride and ethylbenzene:

- C6H4(CO)2O + C6H5Et → C6H4(CO)2C6H3Et + H2O.

Both phthalic anhydride and ethylbenzene are readily available, being otherwise used in the large-scale production of plastics.

Uses

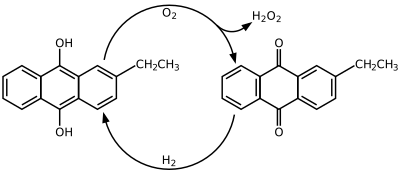

Hydrogen peroxide is produced industrially by the anthraquinone process which involves using 2-alkyl-9,10-anthraquinones for hydrogenation. Many derivatives of anthraquinone are used but 2-ethylanthraquinone is common because of its high selectivity. The hydrogenation of the unsubsituted ring can reach 90% selectivity by using 2-ethylanthraquinone. Hydrogenation follows the Riedl-Pfleiderer, or autoxidation, process:

The hydrogenation of 2-ethylanthraquinone is catalyzed by palladium. Hydrogenation produces both 2-ethylanthrahydroquinone and tetrahydroanthraquinone. The tetrahydro derivative of 2-alkylanthraquinone is easily hyrdrogenated but is more difficult to oxidize. The formation of the tetrahyrdo derivative can be suppressed through the selection of catalysts, solvents, and reaction conditions. Some suggested solvent mixtures are polyalkylated benzenes and alkyl phosphates or tetraalkyl ureas, trimethylbenzenes and alkylcyclohexanol esters, and methylnaphthalene and nonyl alcohols.

References

- ^ Goor, G.; Glenneberg, J.; Jacobi, S. (2007). "Hydrogen Peroxide". Ullmann's Encyclopedia of Industrial Chemistry. Weinheim: Wiley-VCH. doi:10.1002/14356007.a13_443.pub2.

- ^ Römpp CD 2006, Georg Thieme Verlag 2006