KIVA (software): Difference between revisions

Reverted to revision 851788526 by Jiajiaecho (talk): Rv copy paste from another source. (TW) |

ADDED FEARCE - HAS laur status |

||

| Line 49: | Line 49: | ||

===KIVA-4mpi=== |

===KIVA-4mpi=== |

||

Recently, LANL researchers developed KIVA-4mpi, a parallel version of KIVA-4, and the most advanced version of KIVA maintained and distributed by LANL. KIVA-4mpi also solves chemically reacting, turbulent, multi-phase viscous flows, but does this on multiple computer processors with a distributed computational domain (grid). KIVA-4mpi internal combustion engine modeling capabilities are the same as that of KIVA-4, and are based on the KIVA-4 unstructured grid code. The software is well suited for modeling internal combustion engines on multiple processors using the [[message passing interface]] (MPI).<ref>David Torres, Yuanhong Li and Song-Charng Kong, Partitioning Strategies for Parallel KIVA-4 Engine Simulations, Computers and Fluids, 2009</ref> On August 9, 2011, LANL honored the authors of KIVA-4mpi with the Distinguished Copyright Award for demonstrating a breadth of commercial applications, potential to create economic value, and the highest level of technical excellence.<ref>{{cite web|url=http://www.lanl.gov/news/releases/awards_recognize_outstanding_innovation_in_tech_transfer.html|title=Awards recognize outstanding innovation in Technology Transfer |accessdate=October 24, 2011 |deadurl=yes |archiveurl=https://web.archive.org/web/20111021051725/http://www.lanl.gov/news/releases/awards_recognize_outstanding_innovation_in_tech_transfer.html |archivedate=October 21, 2011 }}</ref> |

Recently, LANL researchers developed KIVA-4mpi, a parallel version of KIVA-4, and the most advanced version of KIVA maintained and distributed by LANL. KIVA-4mpi also solves chemically reacting, turbulent, multi-phase viscous flows, but does this on multiple computer processors with a distributed computational domain (grid). KIVA-4mpi internal combustion engine modeling capabilities are the same as that of KIVA-4, and are based on the KIVA-4 unstructured grid code. The software is well suited for modeling internal combustion engines on multiple processors using the [[message passing interface]] (MPI).<ref>David Torres, Yuanhong Li and Song-Charng Kong, Partitioning Strategies for Parallel KIVA-4 Engine Simulations, Computers and Fluids, 2009</ref> On August 9, 2011, LANL honored the authors of KIVA-4mpi with the Distinguished Copyright Award for demonstrating a breadth of commercial applications, potential to create economic value, and the highest level of technical excellence.<ref>{{cite web|url=http://www.lanl.gov/news/releases/awards_recognize_outstanding_innovation_in_tech_transfer.html|title=Awards recognize outstanding innovation in Technology Transfer |accessdate=October 24, 2011 |deadurl=yes |archiveurl=https://web.archive.org/web/20111021051725/http://www.lanl.gov/news/releases/awards_recognize_outstanding_innovation_in_tech_transfer.html |archivedate=October 21, 2011 }}</ref> |

||

===FEARCE=== |

|||

Fast Easy Accurate and Robust Continuum Engineering |

|||

LANL's T-3 (David Carrington and Jiajia Waters) new FEM base software for modeling all types of engines or turbines and general CFD problems, those with multiphases, reactive, turbulent, through all flow regimes. |

|||

Project Introduction |

|||

Our research and development of FEARCE for turbulent reactive and multiphase flow modeling, particularly as related to engine combustion, is relevant to the LANL’s and DOE’s efforts for addressing national energy security. Less dependence on petroleum products leads to greater energy security. By Environmental Protection Agency standards, some vehicles are now reaching 42–50 mpg mark. These are conventional gasoline engines. With continued investment and research into new technical innovations, the potential exists to save another than 4 million barrels of oil per day or approximately $200 to $400 million per day. This would be a significant decrease in emissions and use of petroleum where vehicles account for approximately 20% of greenhouse gas emissions and obviously would be a very large stimulus to the U.S. economy. |

|||

Better understanding of fuel injection and fuel–air mixing, thermodynamic combustion losses, and combustion/emission formation processes enhances our ability to minimize fuel use and unwanted emissions. Helping to accomplish this understanding, the KIVA development program is providing a state-of-the-art capability for accurately simulating combustion processes: to have a predictive methodology in a software helping industry and researchers not only meet national goals on fuel usage and emissions, but global goals. In addition, a predictive, robust, and accurate capability for simulating the engine combustion processes helps to minimize time and labor needed for development of new engine technology. |

|||

Achieving more Predictive, Robust and Accurate Engine Combustion Simulations |

|||

The new software FEARCE provides a state-of-the-art capability for accurately simulating turbulent reactive multi-phase flow with sprays and robust moving immersed parts (valves and pistons or any moving part). Engine combustion processes are becoming more predictive with the new methodology, more predictive than is currently available. FEARCE supplies industry and researchers a tool to help meet national goals on emissions and engine efficiencies. The software is a more predictive, robust, and accurate system for simulating engine combustion processes. To meet these goals, our program provides the following (although not a complete) list of salient attributes: |

|||

• Develop mathematical and computer algorithms and software for the advancement of speed, accuracy, robustness, and range of applicability of KIVA, an internal engine combustion modeling software; to be a more predictive computer code. This is to be accomplished by employing higher-order, spatially accurate methods for reactive turbulent flow and more predictive spray injection, combined with a robust and accurate actuated moving parts process along with more appropriate turbulence modeling. The code combines state-of-the-art chemical reaction simulators such as Chemkin-Pro. |

|||

• Provide engine modeling software that is easier to maintain and is easier to add models to than the current KIVA, reducing code development costs via more modern code architecture. |

|||

• Provide a software capable of producing fast turn-around times needed by industry. The code not only functions well on small computer platforms but addresses high performance computing aspects required for high-fidelity more predictive solutions. |

|||

By designing, inventing, and developing new modeling methods and code the goals are being achieved. The new design is a change of discretization to the finite element method (FEM) from which essentially every other beneficial and salient attribute of the software stems. We invented and developed the following systems to date (details are provided in the referenced publications). |

|||

• Developed the FEM-predictor–corrector scheme projection method for high accuracy and all the benefits the FEM system brings to computational fluid dynamics (CFD) modeling of engines. The CFD solver is applicable to all flow regimes; from incompressible laminar flow to transitional and turbulent compressible flows to hypersonic flows. (Carrington 2009, Carrington et al. 2014, Waters et al. 2016) |

|||

• Developed the ‘h-adaptive’ system for automatic grid refinement in a k-ω turbulence modeling FEM system. (Carrington and Pepper, 2010). |

|||

• Developed the hp-adaptive system for higher order accuracy, where ‘p-adaptation’ is higher order polynomial basis approximation and ‘h-adaptive’ is automatic grid refinement collaboration with Dr. Xiuling Wang of Purdue University (Carrington et al. 2014) |

|||

• Invented a local-arbitrary Lagrangian–Eulerian (ALE) method for moving bodies (Carrington et al. to appear) |

|||

• Developed Immersed Boundary Method (IBM) for moving bodies using the invented marker system and some of the reconstruction techniques in the ALE scheme (Waters et al. 2018) |

|||

• Developed a new FEM form of the Vreman dynamic Large Eddy Simulation (LES) method capable of easily handling highly unsteady and transitional to fully turbulent wall-bounded flows encountered in engines. (Waters et al. 2016) |

|||

o Self-damping turbulence at the walls negates the need for a law-of-the-wall system that, in general, is flawed or violated for unsteady turbulent flow in complex domains |

|||

• Invented and developed Volume of Fluid (VOF) methods in FEM for modeling true multi-phase flow |

|||

o To fully represent the spray break-up process, to have predictive spray modeling (Waters et al. 2017). |

|||

• Developed parallel solution method that is super-linear (Waters and Carrington 2016) |

|||

o Delivers superliner scalability |

|||

o Delivers 30×speed-up over serial code given the same problem and settings |

|||

• Developed implicit solutions methods for 10× speed-up over explicit parallel solver for an overall 300×speed-up over the explicit serial version, based on the same test problems (Waters and Carrington 2016) |

|||

• Invented a method for implementing Message Passing Interface (MPI) for today’s and future platforms (Waters and Carrington 2016). A scheme that only requires local development and integration of the functionals and not requiring the typical ghost cell or flux balancing processes use in traditional CFD. |

|||

• A software that is significantly faster, robust and accurate than our previous finite volume based KIVA-4mpi. A software that is vastly easier to produce computational grids for simulations, meets the goal of going from CAD to CFD easily. |

|||

Some Computational Features |

|||

Our efforts push toward a comprehensive tool for the future with the accomplishment of grid generation, immersed moving part, KH injection spray model, multiphase (liquid and gas) compressible turbulent flow with a dynamic LES for unsteady wall-bounded flow, VOF for predictive initial liquid fuel jet break-up, along with high computational speed. |

|||

Grid Generation |

|||

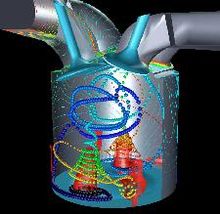

In conjunction with Program Development Company who developed GridPro, we are working on providing high quality grids for the engine system with an eye toward ease of use. The overset immersed moving parts system used allows for easy grid generation of the cylinders and ports. The spark and injector modules are easily inserted into the engine topology. The final process of grid generation, the piston and valves surfaces simply are inserted by overlaying their surface representations after the high quality grid generation is performed automatically by GridPro. The overset moving parts greatly simplifies the gridding process, removing the need to work around immersed bodies, the process required using traditional gridding methods and immersed parts motion. The injector, engine manifolds and spark systems that are represented as topologies, separately, with the idea of making various types of injectors, spark plug and manifolds module topologies, that are simply connected to the engine cylinder topology. The final gridded engine system is shown in Figure 1 with four million cells. Gridding is a major component of CFD, where we provide quality grids with a minimum of labor, very quick and high quality, saving weeks and months on the gridding process over traditional methods. |

|||

Figure 1 - Computational grid using GridPro and overset valve and piston surfaces. In close-up, the valves and the injector module are easily married to the cylinder domain. |

|||

Immersed Moving Parts |

|||

By developing 2nd order spatially accurate immersed boundary methods for moving bodies we achieve a robust moving boundary which floats through the computational grid while maintaining robustness of the solution process -- the grid never becomes distorted. Using the invented marker system that is based on methods used in our local-ALE system for moving bodies, the marker system tracks moving boundary interfaces (Carrington et al. to appear). By employing the FEM shape functions for interpolation an IBM method is created to calculate the fluid’s motion and thermodynamic state at the intersected grid cells or elements (Waters et al. 2018). A two-valve engine test case is functioning shown in Figure 2 using the immersed boundary methods, showing flow over the opening valve at a crank angle of 80° and 640o after top dead center (ATDC). |

|||

a) b) |

|||

Figure 2 - Two-Port engine. (a) Intake valve operating showing the magnitude of velocity and the streamline of the fluid entering at 80° ATDC and (b) Exhaust valve operating showing magnitude of velocity and vectors at 640° ADTC. |

|||

Spray Modeling |

|||

To fully represent the spray break-up process; to produce a predictive spray model system, we’ve developed a VOF scheme in finite element method to produce a system that models true multiphase flow, allowing us to accurately model fuel/liquid jet break-up into ligaments or large drops. The breaking ligaments, once small enough as calculated by the FEM and VOF scheme, is handed-off to a Lagrangian particle method in FEM using either the Rayleigh–Taylor Analogy (TAB) or the new Kelvin Helmholtz (KH) secondary droplet break-up systems to completely model the atomization process. This allows for engineering modeling for the injection system that is more predictive. Figure 3 shows liquid being injected into air at 3 bar through an orifice of 0.01-mm diameter early in time. The liquid inlet is slug flow and laminar. The break-up length is where the wave instabilities are large enough to cause ligamentation, and is found to be five orifice diameters downstream of inlet with our method. This corresponds to the results obtained by direct numerical simulation as reported in Waters et al. (2017) and seen in experimental data. |

|||

a) b) |

|||

Figure 3 - Multiphase flow simulation with VOF method, gasoline injected into quiescent air at 3 bar. (a) Gasoline jet primary break-up into ligaments and (b) primary break-up and w-component of velocity of air showing recirculation. |

|||

By adding the KH-RT spray model (Reitz 1987) and validating on an Engine Combustion Network (ECN) Spray A test case we extend KIVA’s modeling capability from the current Taylor Analogy Break-up (TAB) system. The KH model requires less tuning to experimental data than the TAB system, the tuning being the parameters for initial break-up. So with VOF and KH combined that predicted fluid ligaments can be feed into the KH model for good engineering calculations. The ECN Spray A case with injection of diesel into quiescent nitrogen at 2.2 MPa is shown in Figure 4. Validation continues in collaboration with Oakland University and Texas Technology University. |

|||

Figure 4 - The ECN Spray A case: injection of diesel in quiescent nitrogen at 2.2 MPa, KH-RT spray model |

|||

Computational Efficiency |

|||

Continued work on the parallel solution method delivers superliner scalability (Waters and Carrington 2016) and a code considerable faster than KIVA-4mpi (Los Alamos National Laboratory’s previous unstructured grid code for engines) on the same problems with exact same settings and grid size. On that grid in fact FEARCE is more accurate. Hence, FEARCE produces better accuracy than previous codes and on coarser grids. The new FEM code is capable of being faster on the same resolution as old codes, but is more accurate on less resolved problems, providing additional advantage. Figure 5 demonstrates the ever increasing computational speed versus KIVA-4mpi; at 0.38 s of simulation time, FEARCE is 1.44× faster on a typical test case. The improvement in speed translates to 12× faster than the previous version of parallel KIVA over a single engine cycle. |

|||

Figure 5 - FEARCE’s ever increasing advantage in computational speed over KIVA-4mpi; at 0.38 s of simulation time, FEARCE is 1.44× faster (for the problem being solved by both systems with exactly the same settings) |

|||

FEARCE and the KIVA development program at Los Alamos National Laboratory |

|||

The KIVA development program at Los Alamos National Laboratory is working to achieve the objective of having a robust CFD software for turbulent reactive flow that is particularly well-suited for combustion modeling in engines or machines where immersed moving boundaries are involved. We’ve kept an eye toward solutions being produced on quality grids created with a minimal amount of labor. Our current and future efforts include: |

|||

• Engine solid material modeling and conjugate heat transfer by marrying a Boundary Element Method (BEM) representing the solid material physics to the fluid dynamic FEM solver. |

|||

• Exascale coding because the operations are local to elements (vectorizable), and require very little cross-domain communication. |

|||

• We continue improving memory handling for the hp-adaptive FEM system, testing and improving the multiphase and spray modeling along with improving computational speed and linear equation solution methods. |

|||

• FEARCE is to be a software for industry and researchers via commercialization and collaboration. |

|||

References |

|||

Carrington, D.B. “A characteristic-based split hp-adaptive finite element method for combustion modeling in FEARCE.” LANL Scientific Report no. LA-UR-09-06527, 2009. |

|||

Carrington, D.B. and D.W. Pepper, “An h-Adaptive Finite Element Method for Turbulent Heat Transfer,” Computer Modeling in Engineering & Sciences, Tech Science Press, vol. 61, no 1, pp. 23-44, 2010 |

|||

Carrington, D.B., X. Wang, and D.W. Pepper. “A predictor-corrector split projection method for turbulent reactive flow.” Journal of Computational Thermal Sciences, Begell House Inc., vol. 5, no. 4, pp.333–352, 2014. |

|||

Carrington D.B., X. Wang, and D.W. Pepper. “An hp-adaptive Predictor-Corrector Split Projection Method for Turbulent Compressible Flow.” Proceedings of the 15th International Heat Transfer Conference, IHTC-15, Kyoto, Japan, August 10–15, 2014. |

|||

Carrington, D.B., M. Mazumder, and J.C. Heinrich. “Three-Dimensional Local ALE-FEM Method for Fluid Flow in Domains Containing Moving Boundaries/Objects Interfaces.” Progress in Computational Fluid Dynamics, to appear. |

|||

Waters, J., D.B. Carrington, and B. Philipbar. “'FEARCE 2018 Update: Meshing, Modeling and Methods for Injection, Spray Break-up and Engine Modeling.” Los Alamos Scientific Report no. 'FEARCE 2018 Update: Meshing, Modeling and Methods for Injection, Spray Break-up and Engine Modeling. AEC/HCCI Working Group Meeting at ANL, Chicago, IL, Jan. 29, 2018. |

|||

Waters J., D.B. Carrington, and D.W. Pepper. “An Adaptive Finite Element Method with Dynamic LES for Incompressible and Compressible Flows.” Journal of |

|||

Computational Thermal Sciences, Begell House Inc., Vol.8(1), pp.57–71, 2016. |

|||

Waters, J., D.B. Carrington, and M.M. Francois. “Modeling Multi-phase Flow: Spray Break-up Using Volume of Fluids in a Dynamic LES FEM method.” Numerical Heat Transfer, Part B, vol. 72, no. 4, pp. 285–299, 2017. |

|||

Waters, J., and D.B. Carrington. “A parallel Large Eddy Simulation in a finite element projection method for all flow regimes.” Numerical Heat Transfer, Part A, vol, 70, n0. 2, pp. 117–131, 2016. |

|||

Reitz, R.D. “Modeling Atomization Processes in High-Pressure Vaporizing Sprays.” Atomization and Sprays Technology, vol 3, pp. 309–337, 1987. |

|||

Waters, J., and D.B. Carrington. “A Dynamic Large Eddy Model for Simulating Turbulent Reactive, Flow in Engines: A Parallel adaptive Finite Element Method.” Proceedings of WCX™17: SAE International World Congress Experience, Detroit, MI, April 2–4, 2017. |

|||

Waters, J., D.B. Carrington, X. Wang, and D.W. Pepper. “A Dynamic Large Eddy Model for Simulating Turbulent Reactive Flow with an Adaptive Finite Element Method,” Proceeding of the 2nd Thermal and Fluid Engineering Conference, TFEC2017, ASTFE, Las Vegas, NV, April 2–5, 2017. |

|||

Waters, J, and D.B. Carrington. “Modeling Turbulent Reactive Flow in Internal Combustion Engines with an LES in a semi-implicit/explicit Finite Element Projection Method.” Proceedings of the ASME 2016 Internal Combustion Fall Technical Conference, ICEF2016, Greenville, SC, October 9–12, 2016. |

|||

Waters J., and D.B. Carrington. “Parallel Large Eddy Simulation for Modeling 3D Turbulent Flow in Engines.” Proceedings of the ASME 2016 Fluids Engineering Division Summer Meeting, Washington, DC, July 10–14, 2016. |

|||

===KIVA-EXEC=== |

===KIVA-EXEC=== |

||

Revision as of 06:03, 25 July 2018

KIVA simulation of an experimental engine with DOHC quasi-symmetric pent-roof combustion chamber and 4 valves. | |

| Developer(s) | Los Alamos National Laboratory |

|---|---|

| Initial release | 1985 |

| Stable release | KIVA-4mpi

/ 2009 |

| Operating system | Linux, Unix, Windows |

| Available in | Fortran |

| Type | Physics |

| License | Proprietary |

| Website | www |

KIVA is a family of Fortran-based Computational Fluid Dynamics software developed by Los Alamos National Laboratory (LANL). The software predicts complex fuel and air flows as well as ignition, combustion, and pollutant-formation processes in engines. The KIVA models have been used to understand combustion chemistry processes, such as auto-ignition of fuels, and to optimize diesel engines for high efficiency and low emissions. General Motors has used KIVA in the development of direct-injection, stratified charge gasoline engines as well as the fast burn, homogeneous-charge gasoline engine.[1] Cummins reduced development time and cost by 10%–15% using KIVA to develop its high-efficiency 2007 ISB 6.7-L diesel engine that was able to meet 2010 emission standards in 2007. At the same time, the company realized a more robust design and improved fuel economy while meeting all environmental and customer constraints.[2]

History

LANL's Computational Fluid Dynamics expertise hails from the very beginning of the Manhattan Project in the 1940s. When the nation found itself in the midst of the first energy crisis in the 1970s, this core Laboratory capability transformed into KIVA, an internal combustion engine modeling tool designed to help make automotive engines more fuel-efficient and cleaner-burning. A "kiva" is actually a round Pueblo ceremonial chamber that is set underground and entered from above by means of a ladder through its roof; drawing on LANL's southwestern heritage, an analogy is made with the typical engine cylinder in which the entrance and exit of gases is achieved through valves set in the cylinder.[3]

The first public release of KIVA was made in 1985 through the National Energy Software Center (NESC) at Argonne National Laboratory, which served at the time as the official distribution hub for Department of Energy-sponsored software. Distribution of KIVA continued through the Energy Science and Technology Software Center (ESTSC) in Oak Ridge, Tennessee until 2008, when distribution of multiple versions of KIVA returned to LANL's Technology Transfer Division (TT).[4] KIVA is used by hundreds of institutions worldwide, including the Big Three U.S. auto makers,[1][5][6] Cummins,[2] Caterpillar,[7] and various federal laboratories.[1][8]

Overview

Fuel economy is heavily dependent upon engine efficiency, which in turn depends to a large degree on how fuel is burned within the cylinders of the engine. Higher in-cylinder pressures and temperatures lead to increased fuel economy, but they also create more difficulty in controlling the combustion process. Poorly controlled and incomplete combustion can cause higher levels of emissions and lower engine efficiencies.

In order to optimize combustion processes, engine designers have traditionally undertaken manual engine modifications, conducted testing, and analyzed the results. This iterative process is painstakingly slow, costly, and does not lend itself to identifying the optimal engine design specifications. In response to these problems, Los Alamos National Laboratory scientists developed KIVA, an advanced computational fluid dynamics (CFD) modeling code that accurately simulates the in-cylinder processes of engines.

KIVA, a transient, three-dimensional, multiphase, multicomponent code for the analysis of chemically reacting flows with sprays has been under development at LANL for decades. The code uses an Arbitrary Lagrangian Eulerian (ALE) methodology on a staggered grid, and discretizes space using the finite volume method. The code uses an implicit time-advancement with the exception of the advective terms that are cast in an explicit but second-order monotonicity-preserving manner. Also, the convection calculations can be subcycled in the desired regions to avoid restricting the time step due to Courant conditions.

KIVA’s functionality extends from low speeds to supersonic flows for both laminar and turbulent regimes. Transport and chemical reactions for an arbitrary number of species and their chemical reactions is provided. A stochastic particle method is used to calculate evaporating liquid sprays, including the effects of droplet collisions, agglomeration, and aerodynamic breakups.

Although specifically designed for simulating internal combustion engines, the modularity of the code facilitates easy modifications for solving a variety of hydrodynamics problems involving chemical reactions. The versatility and range of features have made KIVA programs attractive to a variety of non-engine applications as well; these range from convection towers to modeling silicon dioxide condensation in high pressure oxidation chambers. Other applications have included the analysis of flows in automotive catalytic converters, power plant smokestack cleaning, pyrolytic treatment of biomass, design of fire suppression systems, Pulsed Detonation Engines (PDEs), stationary burners, aerosol dispersion, and design of heating, ventilation, and air conditioning systems. The code has found a widespread application in the automotive industry.

Versions

This article or section may have been copied and pasted from another location, possibly in violation of Wikipedia's copyright policy. (June 2018) |

KIVA-3V

KIVA-3V is the most mature version of KIVA still maintained and distributed through LANL; it is an improved version of the earlier Federal Laboratory Consortium Excellence in Technology Transfer Award-winning KIVA3 (1993), extended to model vertical or canted valves in the cylinder head of a gasoline or diesel engine.[9] KIVA3, in turn, was based on the earlier KIVA2 (1989) and used the same numerical solution procedure and solved the same types of equations.[10]

KIVA-3V uses a block-structured mesh with connectivity defined through indirect addressing. The departure from a single rectangular structure in logical space allows complex geometries to be modeled with significantly greater efficiency because large regions of deactivated cells are no longer necessary. Cell-face boundary conditions permit greater flexibility and simplification in the application of boundary conditions. KIVA-3V also contains a number of significant improvements over its predecessors. New features enhanced the robustness, efficiency, and usefulness of the overall program for engine modeling. Automatic restart of the cycle with a reduced timestep in case of iteration limit or temperature overflow effectively reduced code crashes. A new option provided automatic deactivation of a port region when it is closed from the cylinder and reactivation when it communicates with the cylinder. Extensions to the particle-based liquid wall film model made the model more complete and a split injection option was also added. A new subroutine monitors the liquid and gaseous fuel phases and energy balance data and emissions are monitored and printed. In addition, new features were added to the LANL-developed grid generator, K3PREP, and the KIVA graphics post processor, K3POST.[10]

KIVA-4

KIVA-4 is maintained and distributed through LANL. While KIVA-4 maintains the full generality of KIVA-3V, it adds the capability of computing with unstructured grids. Unstructured grids can be generated more easily than structured grids for complex geometries. The unstructured grids may be composed of a variety of elements including hexahedra, prisms, pyramids, and tetrahedra. However, the numerical accuracy diminishes when the grid is not composed of hexahedra. KIVA-4 was developed to work with the many geometries accommodated within KIVA-3V, which includes 2D axisymmetric, 2D planar, 3D axisymmetric sector geometries, and full 3D geometries. KIVA-4 also features a multicomponent fuel evaporation algorithm. Many of the numerical algorithms in KIVA-3V generalize properly to unstructured meshes; however, fundamental changes were needed in the solution of the pressure equation and the fluxing of momentum. In addition, KIVA-4 loops over cell faces to compute diffusion terms.[11]

KIVA-4mpi

Recently, LANL researchers developed KIVA-4mpi, a parallel version of KIVA-4, and the most advanced version of KIVA maintained and distributed by LANL. KIVA-4mpi also solves chemically reacting, turbulent, multi-phase viscous flows, but does this on multiple computer processors with a distributed computational domain (grid). KIVA-4mpi internal combustion engine modeling capabilities are the same as that of KIVA-4, and are based on the KIVA-4 unstructured grid code. The software is well suited for modeling internal combustion engines on multiple processors using the message passing interface (MPI).[12] On August 9, 2011, LANL honored the authors of KIVA-4mpi with the Distinguished Copyright Award for demonstrating a breadth of commercial applications, potential to create economic value, and the highest level of technical excellence.[13]

FEARCE

Fast Easy Accurate and Robust Continuum Engineering LANL's T-3 (David Carrington and Jiajia Waters) new FEM base software for modeling all types of engines or turbines and general CFD problems, those with multiphases, reactive, turbulent, through all flow regimes.

Project Introduction Our research and development of FEARCE for turbulent reactive and multiphase flow modeling, particularly as related to engine combustion, is relevant to the LANL’s and DOE’s efforts for addressing national energy security. Less dependence on petroleum products leads to greater energy security. By Environmental Protection Agency standards, some vehicles are now reaching 42–50 mpg mark. These are conventional gasoline engines. With continued investment and research into new technical innovations, the potential exists to save another than 4 million barrels of oil per day or approximately $200 to $400 million per day. This would be a significant decrease in emissions and use of petroleum where vehicles account for approximately 20% of greenhouse gas emissions and obviously would be a very large stimulus to the U.S. economy. Better understanding of fuel injection and fuel–air mixing, thermodynamic combustion losses, and combustion/emission formation processes enhances our ability to minimize fuel use and unwanted emissions. Helping to accomplish this understanding, the KIVA development program is providing a state-of-the-art capability for accurately simulating combustion processes: to have a predictive methodology in a software helping industry and researchers not only meet national goals on fuel usage and emissions, but global goals. In addition, a predictive, robust, and accurate capability for simulating the engine combustion processes helps to minimize time and labor needed for development of new engine technology.

Achieving more Predictive, Robust and Accurate Engine Combustion Simulations The new software FEARCE provides a state-of-the-art capability for accurately simulating turbulent reactive multi-phase flow with sprays and robust moving immersed parts (valves and pistons or any moving part). Engine combustion processes are becoming more predictive with the new methodology, more predictive than is currently available. FEARCE supplies industry and researchers a tool to help meet national goals on emissions and engine efficiencies. The software is a more predictive, robust, and accurate system for simulating engine combustion processes. To meet these goals, our program provides the following (although not a complete) list of salient attributes:

• Develop mathematical and computer algorithms and software for the advancement of speed, accuracy, robustness, and range of applicability of KIVA, an internal engine combustion modeling software; to be a more predictive computer code. This is to be accomplished by employing higher-order, spatially accurate methods for reactive turbulent flow and more predictive spray injection, combined with a robust and accurate actuated moving parts process along with more appropriate turbulence modeling. The code combines state-of-the-art chemical reaction simulators such as Chemkin-Pro.

• Provide engine modeling software that is easier to maintain and is easier to add models to than the current KIVA, reducing code development costs via more modern code architecture.

• Provide a software capable of producing fast turn-around times needed by industry. The code not only functions well on small computer platforms but addresses high performance computing aspects required for high-fidelity more predictive solutions.

By designing, inventing, and developing new modeling methods and code the goals are being achieved. The new design is a change of discretization to the finite element method (FEM) from which essentially every other beneficial and salient attribute of the software stems. We invented and developed the following systems to date (details are provided in the referenced publications).

• Developed the FEM-predictor–corrector scheme projection method for high accuracy and all the benefits the FEM system brings to computational fluid dynamics (CFD) modeling of engines. The CFD solver is applicable to all flow regimes; from incompressible laminar flow to transitional and turbulent compressible flows to hypersonic flows. (Carrington 2009, Carrington et al. 2014, Waters et al. 2016)

• Developed the ‘h-adaptive’ system for automatic grid refinement in a k-ω turbulence modeling FEM system. (Carrington and Pepper, 2010).

• Developed the hp-adaptive system for higher order accuracy, where ‘p-adaptation’ is higher order polynomial basis approximation and ‘h-adaptive’ is automatic grid refinement collaboration with Dr. Xiuling Wang of Purdue University (Carrington et al. 2014)

• Invented a local-arbitrary Lagrangian–Eulerian (ALE) method for moving bodies (Carrington et al. to appear)

• Developed Immersed Boundary Method (IBM) for moving bodies using the invented marker system and some of the reconstruction techniques in the ALE scheme (Waters et al. 2018)

• Developed a new FEM form of the Vreman dynamic Large Eddy Simulation (LES) method capable of easily handling highly unsteady and transitional to fully turbulent wall-bounded flows encountered in engines. (Waters et al. 2016)

o Self-damping turbulence at the walls negates the need for a law-of-the-wall system that, in general, is flawed or violated for unsteady turbulent flow in complex domains

• Invented and developed Volume of Fluid (VOF) methods in FEM for modeling true multi-phase flow

o To fully represent the spray break-up process, to have predictive spray modeling (Waters et al. 2017).

• Developed parallel solution method that is super-linear (Waters and Carrington 2016)

o Delivers superliner scalability

o Delivers 30×speed-up over serial code given the same problem and settings

• Developed implicit solutions methods for 10× speed-up over explicit parallel solver for an overall 300×speed-up over the explicit serial version, based on the same test problems (Waters and Carrington 2016)

• Invented a method for implementing Message Passing Interface (MPI) for today’s and future platforms (Waters and Carrington 2016). A scheme that only requires local development and integration of the functionals and not requiring the typical ghost cell or flux balancing processes use in traditional CFD.

• A software that is significantly faster, robust and accurate than our previous finite volume based KIVA-4mpi. A software that is vastly easier to produce computational grids for simulations, meets the goal of going from CAD to CFD easily.

Some Computational Features Our efforts push toward a comprehensive tool for the future with the accomplishment of grid generation, immersed moving part, KH injection spray model, multiphase (liquid and gas) compressible turbulent flow with a dynamic LES for unsteady wall-bounded flow, VOF for predictive initial liquid fuel jet break-up, along with high computational speed.

Grid Generation In conjunction with Program Development Company who developed GridPro, we are working on providing high quality grids for the engine system with an eye toward ease of use. The overset immersed moving parts system used allows for easy grid generation of the cylinders and ports. The spark and injector modules are easily inserted into the engine topology. The final process of grid generation, the piston and valves surfaces simply are inserted by overlaying their surface representations after the high quality grid generation is performed automatically by GridPro. The overset moving parts greatly simplifies the gridding process, removing the need to work around immersed bodies, the process required using traditional gridding methods and immersed parts motion. The injector, engine manifolds and spark systems that are represented as topologies, separately, with the idea of making various types of injectors, spark plug and manifolds module topologies, that are simply connected to the engine cylinder topology. The final gridded engine system is shown in Figure 1 with four million cells. Gridding is a major component of CFD, where we provide quality grids with a minimum of labor, very quick and high quality, saving weeks and months on the gridding process over traditional methods.

Figure 1 - Computational grid using GridPro and overset valve and piston surfaces. In close-up, the valves and the injector module are easily married to the cylinder domain.

Immersed Moving Parts By developing 2nd order spatially accurate immersed boundary methods for moving bodies we achieve a robust moving boundary which floats through the computational grid while maintaining robustness of the solution process -- the grid never becomes distorted. Using the invented marker system that is based on methods used in our local-ALE system for moving bodies, the marker system tracks moving boundary interfaces (Carrington et al. to appear). By employing the FEM shape functions for interpolation an IBM method is created to calculate the fluid’s motion and thermodynamic state at the intersected grid cells or elements (Waters et al. 2018). A two-valve engine test case is functioning shown in Figure 2 using the immersed boundary methods, showing flow over the opening valve at a crank angle of 80° and 640o after top dead center (ATDC).

a) b)

Figure 2 - Two-Port engine. (a) Intake valve operating showing the magnitude of velocity and the streamline of the fluid entering at 80° ATDC and (b) Exhaust valve operating showing magnitude of velocity and vectors at 640° ADTC.

Spray Modeling To fully represent the spray break-up process; to produce a predictive spray model system, we’ve developed a VOF scheme in finite element method to produce a system that models true multiphase flow, allowing us to accurately model fuel/liquid jet break-up into ligaments or large drops. The breaking ligaments, once small enough as calculated by the FEM and VOF scheme, is handed-off to a Lagrangian particle method in FEM using either the Rayleigh–Taylor Analogy (TAB) or the new Kelvin Helmholtz (KH) secondary droplet break-up systems to completely model the atomization process. This allows for engineering modeling for the injection system that is more predictive. Figure 3 shows liquid being injected into air at 3 bar through an orifice of 0.01-mm diameter early in time. The liquid inlet is slug flow and laminar. The break-up length is where the wave instabilities are large enough to cause ligamentation, and is found to be five orifice diameters downstream of inlet with our method. This corresponds to the results obtained by direct numerical simulation as reported in Waters et al. (2017) and seen in experimental data.

a) b)

Figure 3 - Multiphase flow simulation with VOF method, gasoline injected into quiescent air at 3 bar. (a) Gasoline jet primary break-up into ligaments and (b) primary break-up and w-component of velocity of air showing recirculation. By adding the KH-RT spray model (Reitz 1987) and validating on an Engine Combustion Network (ECN) Spray A test case we extend KIVA’s modeling capability from the current Taylor Analogy Break-up (TAB) system. The KH model requires less tuning to experimental data than the TAB system, the tuning being the parameters for initial break-up. So with VOF and KH combined that predicted fluid ligaments can be feed into the KH model for good engineering calculations. The ECN Spray A case with injection of diesel into quiescent nitrogen at 2.2 MPa is shown in Figure 4. Validation continues in collaboration with Oakland University and Texas Technology University.

Figure 4 - The ECN Spray A case: injection of diesel in quiescent nitrogen at 2.2 MPa, KH-RT spray model

Computational Efficiency Continued work on the parallel solution method delivers superliner scalability (Waters and Carrington 2016) and a code considerable faster than KIVA-4mpi (Los Alamos National Laboratory’s previous unstructured grid code for engines) on the same problems with exact same settings and grid size. On that grid in fact FEARCE is more accurate. Hence, FEARCE produces better accuracy than previous codes and on coarser grids. The new FEM code is capable of being faster on the same resolution as old codes, but is more accurate on less resolved problems, providing additional advantage. Figure 5 demonstrates the ever increasing computational speed versus KIVA-4mpi; at 0.38 s of simulation time, FEARCE is 1.44× faster on a typical test case. The improvement in speed translates to 12× faster than the previous version of parallel KIVA over a single engine cycle. Figure 5 - FEARCE’s ever increasing advantage in computational speed over KIVA-4mpi; at 0.38 s of simulation time, FEARCE is 1.44× faster (for the problem being solved by both systems with exactly the same settings)

FEARCE and the KIVA development program at Los Alamos National Laboratory The KIVA development program at Los Alamos National Laboratory is working to achieve the objective of having a robust CFD software for turbulent reactive flow that is particularly well-suited for combustion modeling in engines or machines where immersed moving boundaries are involved. We’ve kept an eye toward solutions being produced on quality grids created with a minimal amount of labor. Our current and future efforts include:

• Engine solid material modeling and conjugate heat transfer by marrying a Boundary Element Method (BEM) representing the solid material physics to the fluid dynamic FEM solver.

• Exascale coding because the operations are local to elements (vectorizable), and require very little cross-domain communication.

• We continue improving memory handling for the hp-adaptive FEM system, testing and improving the multiphase and spray modeling along with improving computational speed and linear equation solution methods.

• FEARCE is to be a software for industry and researchers via commercialization and collaboration.

References Carrington, D.B. “A characteristic-based split hp-adaptive finite element method for combustion modeling in FEARCE.” LANL Scientific Report no. LA-UR-09-06527, 2009. Carrington, D.B. and D.W. Pepper, “An h-Adaptive Finite Element Method for Turbulent Heat Transfer,” Computer Modeling in Engineering & Sciences, Tech Science Press, vol. 61, no 1, pp. 23-44, 2010 Carrington, D.B., X. Wang, and D.W. Pepper. “A predictor-corrector split projection method for turbulent reactive flow.” Journal of Computational Thermal Sciences, Begell House Inc., vol. 5, no. 4, pp.333–352, 2014. Carrington D.B., X. Wang, and D.W. Pepper. “An hp-adaptive Predictor-Corrector Split Projection Method for Turbulent Compressible Flow.” Proceedings of the 15th International Heat Transfer Conference, IHTC-15, Kyoto, Japan, August 10–15, 2014. Carrington, D.B., M. Mazumder, and J.C. Heinrich. “Three-Dimensional Local ALE-FEM Method for Fluid Flow in Domains Containing Moving Boundaries/Objects Interfaces.” Progress in Computational Fluid Dynamics, to appear. Waters, J., D.B. Carrington, and B. Philipbar. “'FEARCE 2018 Update: Meshing, Modeling and Methods for Injection, Spray Break-up and Engine Modeling.” Los Alamos Scientific Report no. 'FEARCE 2018 Update: Meshing, Modeling and Methods for Injection, Spray Break-up and Engine Modeling. AEC/HCCI Working Group Meeting at ANL, Chicago, IL, Jan. 29, 2018. Waters J., D.B. Carrington, and D.W. Pepper. “An Adaptive Finite Element Method with Dynamic LES for Incompressible and Compressible Flows.” Journal of

Computational Thermal Sciences, Begell House Inc., Vol.8(1), pp.57–71, 2016.

Waters, J., D.B. Carrington, and M.M. Francois. “Modeling Multi-phase Flow: Spray Break-up Using Volume of Fluids in a Dynamic LES FEM method.” Numerical Heat Transfer, Part B, vol. 72, no. 4, pp. 285–299, 2017. Waters, J., and D.B. Carrington. “A parallel Large Eddy Simulation in a finite element projection method for all flow regimes.” Numerical Heat Transfer, Part A, vol, 70, n0. 2, pp. 117–131, 2016. Reitz, R.D. “Modeling Atomization Processes in High-Pressure Vaporizing Sprays.” Atomization and Sprays Technology, vol 3, pp. 309–337, 1987. Waters, J., and D.B. Carrington. “A Dynamic Large Eddy Model for Simulating Turbulent Reactive, Flow in Engines: A Parallel adaptive Finite Element Method.” Proceedings of WCX™17: SAE International World Congress Experience, Detroit, MI, April 2–4, 2017. Waters, J., D.B. Carrington, X. Wang, and D.W. Pepper. “A Dynamic Large Eddy Model for Simulating Turbulent Reactive Flow with an Adaptive Finite Element Method,” Proceeding of the 2nd Thermal and Fluid Engineering Conference, TFEC2017, ASTFE, Las Vegas, NV, April 2–5, 2017. Waters, J, and D.B. Carrington. “Modeling Turbulent Reactive Flow in Internal Combustion Engines with an LES in a semi-implicit/explicit Finite Element Projection Method.” Proceedings of the ASME 2016 Internal Combustion Fall Technical Conference, ICEF2016, Greenville, SC, October 9–12, 2016. Waters J., and D.B. Carrington. “Parallel Large Eddy Simulation for Modeling 3D Turbulent Flow in Engines.” Proceedings of the ASME 2016 Fluids Engineering Division Summer Meeting, Washington, DC, July 10–14, 2016.

KIVA-EXEC

KIVA-EXEC is a free, reduced-functionality executable-only trial version of KIVA-4. KIVA-EXEC has all the performance of Los Alamos National Laboratory’s premier KIVA-4 code, but with a 45K cell limitation.[14] KIVA-EXEC is perfect for beginners who do not need or intend to modify the source code.[15]

KIVA videos

- KIVA4 slant valve[16]

- Cubit scalloped bowl[17]

- 4 Valve KIVA-4 mpi[18]

- 4 Valve FEARCE , 2018 new FEM based LANL T-3 software (David Carrington and Jiajia Waters )

Alternative software

- Advanced Simulation Library (open source: AGPL)[19]

- COMSOL Multiphysics

- CLAWPACK[20]

- Code Saturne (GPL)

- Coolfluid (LGPLv3)[21]

- deal.II[22]

- FEATool Multiphysics[23]

- FreeCFD[citation needed]

- Gerris Flow Solver[24]

- Nektar++[25]

- OpenFVM[26]

- SU2 code (LGPL)[27]

References

- ^ a b c "Modeling of Combustion Processes Improves Engine Efficiency" (PDF). Eere.energy.gov. Retrieved 2016-09-27.

- ^ a b "Vehicle Technologies Program : Advanced Combustion Engine R&D: Goals, Strategies, and Top Accomplishments" (PDF). Eere.energy.gov. Retrieved 2016-09-27.

- ^ Amsden, D. C., Amsden, and A. A., The KIVA Story: A Paradigm of Technology Transfer, IEEE Transactions on Professional Communication Journal, 36, (4), 190-195, December 1993

- ^ "Archived copy" (PDF). Archived from the original (PDF) on 2011-10-26. Retrieved 2011-10-24.

{{cite web}}: Unknown parameter|deadurl=ignored (|url-status=suggested) (help)CS1 maint: archived copy as title (link) - ^ "Computational Engine Modeling". Ornl.gov. Retrieved 2012-12-11.

- ^ "Microsoft Word - cst_paper_revised_FINAL.doc" (PDF). Personal.umich.edu. Retrieved 2016-09-27.

- ^ "Energy Systems | Argonne National Laboratory" (PDF). Transportation.anl.gov. Retrieved 2016-09-27.

- ^ "Automotive HCCI Engine Research" (PDF). Eere.energy.gov. Retrieved 2016-09-27.

- ^ Office of Science (2012-06-21). "1993 Awards | U.S. DOE Office of Science (SC)". Science.energy.gov. Retrieved 2012-12-11.

- ^ a b "ESTSC - Find the latest in U.S. Department of Energy Software". Osti.gov. 1999-11-29. Retrieved 2012-12-11.

- ^ Torres, D.J. and Trujillo, M.F., KIVA-4: An unstructured ALE code for compressible gas flow with sprays, Journal of Computational Physics, 2006, vol. 219, pp. 943-975.

- ^ David Torres, Yuanhong Li and Song-Charng Kong, Partitioning Strategies for Parallel KIVA-4 Engine Simulations, Computers and Fluids, 2009

- ^ "Awards recognize outstanding innovation in Technology Transfer". Archived from the original on October 21, 2011. Retrieved October 24, 2011.

{{cite web}}: Unknown parameter|deadurl=ignored (|url-status=suggested) (help) - ^ Los Alamos National Laboratory • Established 1943. "KIVA-4: Los Alamos National Laboratory". Lanl.gov. Retrieved 2012-12-11.

{{cite web}}: CS1 maint: multiple names: authors list (link) CS1 maint: numeric names: authors list (link) - ^ Los Alamos National Laboratory • Est 1943. "LANL | TT | License | Software | 2010". Lanl.gov. Retrieved 2012-12-11.

{{cite web}}: CS1 maint: multiple names: authors list (link) CS1 maint: numeric names: authors list (link) - ^ "Archived copy". Archived from the original on 2011-10-31. Retrieved 2011-10-24.

{{cite web}}: Unknown parameter|deadurl=ignored (|url-status=suggested) (help)CS1 maint: archived copy as title (link) - ^ "Archived copy". Archived from the original on 2011-10-31. Retrieved 2011-10-24.

{{cite web}}: Unknown parameter|deadurl=ignored (|url-status=suggested) (help)CS1 maint: archived copy as title (link) - ^ "Archived copy". Archived from the original on 2011-10-31. Retrieved 2011-10-24.

{{cite web}}: Unknown parameter|deadurl=ignored (|url-status=suggested) (help)CS1 maint: archived copy as title (link) - ^ "Advanced Simulation Library". ASL. Retrieved 2016-09-27.

- ^ "Clawpack". Depts.washington.edu. 2013-01-21. Retrieved 2016-09-27.

- ^ andrealani. "Home · andrealani/COOLFluiD Wiki · GitHub". Github.com. Retrieved 2016-09-27.

- ^ [1] Archived 2012-06-08 at the Wayback Machine

- ^ "FEATool Multiphysics - Matlab FEM Finite Element Physics Simulation Toolbox". Featool.com. Retrieved 2016-09-27.

- ^ "Gerris Flow Solver". Gfs.sf.net. Retrieved 2016-09-27.

- ^ "Nektar++ – Spectral/hp Element Framework". Nektar.info. Retrieved 2016-06-14.

- ^ "OpenFVM download". SourceForge.net. Retrieved 2016-09-27.

- ^ "SU2, the open-source CFD code". Su2.stanford.edu. doi:10.1016/j.compfluid.2016.02.003. Retrieved 2016-09-27.

External links

- Free, personal-use Linux-compatible (Red Hat recommended) KIVA-EXEC download

- KIVA-4 User’s Manual

- KIVA-3V manual (0.4MB, searchable within READER.)

- KIVA-3V manual (1.5MB, searchable within READER.)

- KIVA-3 manual (2.2 MB, searchable within READER.)

- KIVA-II manual (9.0MB, scanned document, not searchable.)

- Los Alamos National Laboratory’s Fluid Dynamics and Solid Mechanics Group

- Los Alamos National Laboratory Technology Transfer Division