Draft:Manufacturing of the International Space Station: Difference between revisions

| Line 660: | Line 660: | ||

Cargo bags for MPLM modules are filled with their cargo such as food packages, science experiments and other miscellaneous items on-site in the SSPF, and are loaded into the module by the same robotic crane and strapped in securely. |

Cargo bags for MPLM modules are filled with their cargo such as food packages, science experiments and other miscellaneous items on-site in the SSPF, and are loaded into the module by the same robotic crane and strapped in securely. |

||

<gallery> |

|||

File:STS-129 ExPRESS Logistics Carrier 11.jpg|ExPRESS logistics carrier assembly |

|||

File:STS-130 Training Kathryn Hire takes a tour of the Tranquility module.jpg|Workers in protective clothing inspect and clean the interior of Node 3 |

|||

File:Coupe-module-ISS.png|ISPR rack configuration in a typical module |

|||

File:STS-131 MPLM Leonardo preparations 2.jpg|Robotic crane arm loading cargo bags in an MPLM |

|||

File:STS-135 crew inspects the Raffaello multi-purpose logistics module.jpg|Workers fitting and inspecting the rack mounts |

|||

File:STS131-Leonardo preparations4.jpg|Workers loading rack covers |

|||

File:STS131-leonardo-preparation1.jpg|Leonardo MPLM in its housing jig |

|||

File:Kibo ICS in KSC-01.jpg|Checking and testing the antenna |

|||

File:First system rack for the Destiny lab module.jpg|A rack being fitted in the Destiny laboratory |

|||

</gallery> |

|||

===Operations and Checkout Building=== |

===Operations and Checkout Building=== |

||

Revision as of 11:49, 22 April 2019

| Draft article not currently submitted for review.

This is a draft Articles for creation (AfC) submission. It is not currently pending review. While there are no deadlines, abandoned drafts may be deleted after six months. To edit the draft click on the "Edit" tab at the top of the window. To be accepted, a draft should:

It is strongly discouraged to write about yourself, your business or employer. If you do so, you must declare it. This draft has not been edited in over six months and qualifies to be deleted per CSD G13.

Where to get help

How to improve a draft

You can also browse Wikipedia:Featured articles and Wikipedia:Good articles to find examples of Wikipedia's best writing on topics similar to your proposed article. Improving your odds of a speedy review To improve your odds of a faster review, tag your draft with relevant WikiProject tags using the button below. This will let reviewers know a new draft has been submitted in their area of interest. For instance, if you wrote about a female astronomer, you would want to add the Biography, Astronomy, and Women scientists tags. Editor resources

Last edited by Raphael.concorde (talk | contribs) 5 years ago. (Update) |

The project to create the International Space Station required the utilization and/or construction of new and existing manufacturing facilities around the world, mostly in the United States and Europe. The agencies overseeing the manufacturing involved NASA, Roscosmos, the European Space Agency, JAXA, and the Canadian Space Agency. Hundreds of contractors[1] working for the five space agencies were assigned the task of fabricating the modules, trusses, experiments and other hardware elements for the station, and launching them individually in modular segments for the in-orbit assembly.

The fact that the project involved the co-operation of fifteen countries working together created engineering challenges that had to be overcome: most notably the differences in language, culture and politics, but also engineering processes, management, measuring standards and communication; to ensure that all elements connect together and function according to plan. The ISS agreement program also called for the station components to be made highly durable and versatile - as it is intended to be used by astronauts indefinitely. A series of new engineering and manufacturing processes and equipment were developed, and shipments of steel, aluminum and other materials were needed for the construction of the space station components.[2]

History and planning

The project, which began as an American effort, was long delayed by funding and technical problems. Originally called Space Station Freedom in the 1980s by Ronald Reagan, who authorized the National Aeronautics and Space Administration (NASA) to build it within 10 years, it was redesigned in the 1990s to reduce costs and expand international involvement, at which time it was renamed. In 1993 the United States and Russia agreed to merge their separate space station plans into a single facility integrating their respective modules and incorporating contributions from the European Space Agency and Japan.[3] In later months, an international agreement board recruited several more space agencies and companies to collaborate to the project. The International Organization for Standardization played a crutial role in unifying and overcoming different engineering methods, languages, standards and teqniques to ensure quality, engineering communication and logistical management across all manufacturing activities of the station components.

Engineering designs

Technical blueprints

-

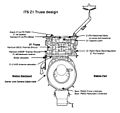

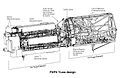

Z1 Truss design

-

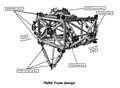

S0 Truss design

-

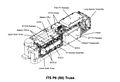

P1 / S1 Truss design

-

P3/4 / S3/4 Truss design

-

P5 / S5 Truss design

-

P6 / S6 Truss design

-

Radiator panels

-

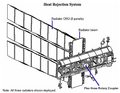

External stowage platform 1

-

Technical blueprint of components

-

Exploded view of truss sections

-

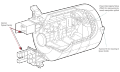

US laboratory

-

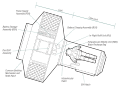

Quest airlock (plan view)

-

Quest airlock Isometric view

-

Node 1

-

Node 2

-

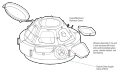

Cupola

-

Columbus

-

Pirs

-

Poisk

-

Rassvet

-

Japanese Experiment Module

-

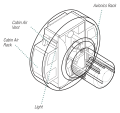

Typical ISS rack

-

Pressurized mating adapters

-

ISS elements as of June 2017[update]

-

Zvezda service module

-

Zarya FGB

Manufacturing Information and Processes

List of factories and manufacturing processes used in the construction and fabrication of the International Space Station modular components:

Transportation

Once manufactured or fabricated sufficiently, most of the space station elements were transported by aircraft (usually the Airbus Beluga or the Antonov An-124) to the Kennedy Space Center Space Station Processing Facility for final manufacturing stages, checks and launch processing.

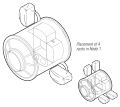

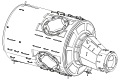

Each module for aircraft transport was safely housed in a custom-designed shipping container with foam insulation and an outer shell of sheet metal, to protect it from damage and the elements. At their respective European, Russian and Japanese factories, the modules were transported to their nearest airport by road in their containers, loaded into the cargo aircraft and were flown to Kennedy Space Center's Shuttle Landing Facility for unloading and final transfers to the SSPF and or the Operations and Checkout Building in the KSC industrial area. The American and Canadian-built components such as the US lab, Node 1, Quest airlock, truss and solar array segments, and the Canadarm-2 were either flown by the Aero Spacelines Super Guppy to KSC, or transported by road and rail.

After final stages of manufacturing, systems testing and launch checkout, all ISS components are loaded into a payload transfer container in the shape of the Space Shuttle payload bay. This container safely carries the component in its launch configuration until it is hoisted vertically at the launch pad gantry for transfer to the Space Shuttle orbiter for launch and in-orbit assembly of the International Space Station.

-

Columbus entering the SSPF loading yard for launch processing

-

Airbus Beluga loading

-

Unloading the Columbus module in its container at the shuttle landing facility

-

Transportation container

-

Antonov An-124 arrives at KSC with the Kibo module from the Tanegashima Space Center in Japan

-

The Rassvet module in its container at KSC being unloaded from the Antonov 124 inbound from Khrunichev

-

Node 3 being hoisted by cranes before loading onto truck

-

ISS payload transfer container

-

The US laboratory module being moved vertically from the payload transfer container to the Space Shuttle orbiter inside its installation structure

Final manufacturing and launch processing stages

With the exception of all but one Russian-built module: Rassvet, all ISS components end up here at either one or both of these buildings at Kennedy Space Center.

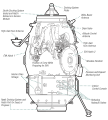

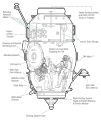

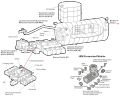

Space Station Processing Facility

At the SSPF, ISS modules, trusses and solar arrays are prepped and made ready for launch. In this iconic building are two large 100,000 class clean work environment areas.[26] Workers and engineers wear full non-contaminant clothing while working. Modules receive cleaning and polishing, and some areas are temporarily disassembled for the installation of cables, electrical systems and plumbing. In another area, shipments of spare materials are available for installation. International Standard Payload Rack frames are assembled and welded together, allowing the installation of instruments, machines and science experiment boxes to be fitted. Once racks are fully assembled, they are hoisted by a special manually operated robotic crane and carefully maneuvered into place inside the space station modules. Each rack weighs from 700 to 1,100 kg, and connect inside the module on special mounts with screws and latches.

Cargo bags for MPLM modules are filled with their cargo such as food packages, science experiments and other miscellaneous items on-site in the SSPF, and are loaded into the module by the same robotic crane and strapped in securely.

-

ExPRESS logistics carrier assembly

-

Workers in protective clothing inspect and clean the interior of Node 3

-

ISPR rack configuration in a typical module

-

Robotic crane arm loading cargo bags in an MPLM

-

Workers fitting and inspecting the rack mounts

-

Workers loading rack covers

-

Leonardo MPLM in its housing jig

-

Checking and testing the antenna

-

A rack being fitted in the Destiny laboratory

Operations and Checkout Building

References

- ^ https://www.esa.int/Our_Activities/Human_and_Robotic_Exploration/International_Space_Station/Companies_involved_with_ISS

- ^ https://www.nasa.gov/mission_pages/station/structure/elements/integrated-truss-structure

- ^ https://www.britannica.com/topic/International-Space-Station

- ^ Wade, Mark (15 July 2008). "ISS Zarya". Encyclopaedia Astronautica. Archived from the original on 27 February 2009. Retrieved 2009-03-11.

{{cite web}}: Unknown parameter|deadurl=ignored (|url-status=suggested) (help) - ^ "Unity Connecting Module: Cornerstone for a Home in Orbit" (PDF). NASA. January 1999. Archived from the original (PDF) on 17 March 2009. Retrieved 2009-03-11.

{{cite web}}: Unknown parameter|deadurl=ignored (|url-status=suggested) (help) - ^ "Zvezda Service Module". NASA. 11 March 2009. Archived from the original on 23 March 2009. Retrieved 2009-03-11.

{{cite web}}: Unknown parameter|deadurl=ignored (|url-status=suggested) (help) - ^ "US Destiny Laboratory". NASA. 26 March 2007. Archived from the original on 9 July 2007. Retrieved 2007-06-26.

{{cite web}}: Unknown parameter|deadurl=ignored (|url-status=suggested) (help) - ^ https://www.nasa.gov/centers/goddard/images/content/402222main_Techs_working_on_ELC_1019.jpg

- ^ "Space Station Extravehicular Activity". NASA. 4 April 2004. Archived from the original on 3 April 2009. Retrieved 2009-03-11.

{{cite web}}: Unknown parameter|deadurl=ignored (|url-status=suggested) (help) - ^ "Space Station Assembly: Integrated Truss Structure". NASA. Archived from the original on 7 December 2007. Retrieved 2007-12-02.

{{cite web}}: Unknown parameter|deadurl=ignored (|url-status=suggested) (help) - ^ "P3 and P4 to expand station capabilities, providing a third and fourth solar array" (pdf). Boeing. July 2006. Retrieved 2007-12-02.

- ^ "STS-118 MISSION OVERVIEW: BUILD THE STATION…BUILD THE FUTURE" (PDF). NASA PAO. July 2007. Archived from the original (PDF) on 1 December 2007. Retrieved 2007-12-02.

{{cite web}}: Unknown parameter|deadurl=ignored (|url-status=suggested) (help) - ^ "Columbus laboratory". ESA. 10 January 2009. Archived from the original on 30 March 2009. Retrieved 2009-03-06.

{{cite web}}: Unknown parameter|deadurl=ignored (|url-status=suggested) (help) - ^ "About Kibo". JAXA. 25 September 2008. Archived from the original on 10 March 2009. Retrieved 2009-03-06.

{{cite web}}: Unknown parameter|deadurl=ignored (|url-status=suggested) (help) - ^ "Kibo Japanese Experiment Module". NASA. 23 November 2007. Archived from the original on 23 October 2008. Retrieved 2008-11-22.

{{cite web}}: Unknown parameter|deadurl=ignored (|url-status=suggested) (help) - ^ Zak, Anatoly. "Docking Compartment-1 and 2". RussianSpaceWeb.com. Archived from the original on 10 February 2009. Retrieved 26 March 2009.

{{cite web}}: Unknown parameter|deadurl=ignored (|url-status=suggested) (help) - ^ Bergin, Chris (9 November 2009). "Russian module launches via Soyuz for Thursday ISS docking". NASASpaceflight.com. Archived from the original on 13 November 2009. Retrieved 10 November 2009.

{{cite web}}: Unknown parameter|deadurl=ignored (|url-status=suggested) (help) - ^ "NASA Extends Contract With Russia's Federal Space Agency" (Press release). NASA. 9 April 2007. Archived from the original on 23 June 2007. Retrieved 2007-06-15.

{{cite press release}}: Unknown parameter|deadurl=ignored (|url-status=suggested) (help) - ^ "NASA to Test Bigelow Expandable Module on Space Station". NASA. 16 January 2013. Retrieved 16 January 2013.

- ^ Frommert, Hartmut (8 December 2018). "International Space Station Flight Schedule". Retrieved 10 December 2018.

- ^ Pietrobon, Steven (19 January 2019). "United States Commercial ELV Launch Manifest". Retrieved 19 January 2019.

- ^ http://nanoracks.com/nanoracks-adds-thales-alenia-space-to-airlock/

- ^ "FGB-based Multipurpose Lab Module (MLM)". Khrunichev State Research and Production Space Centre. Archived from the original on 27 September 2007. Retrieved 2008-10-31.

- ^ Pietrobon, Steven (8 February 2019). "Russian Launch Manifest". Retrieved 8 February 2019.

- ^ a b "Рогозин — РБК: "Формула "космос вне политики" не работает"" [Rogozin to RBC: The "cosmos out of politics" formula does not work]. RBC.ru (in Russian). 10 January 2019. Retrieved 12 January 2019.

- ^ https://science.ksc.nasa.gov/facilities/sspf.html

![ISS elements as of June 2017[update]](/upwiki/wikipedia/commons/thumb/c/ca/ISS_configuration_2017-06_en.svg/120px-ISS_configuration_2017-06_en.svg.png)