Werkspoor: Difference between revisions

Add the rolling mill at het Funen |

Add the Moerdijk bridge |

||

| Line 267: | Line 267: | ||

The company ''Van Vlissingen en Co.'' then seems to have been incorporated into Van Vlissingen & Dudok van Heel in 1866.{{sfn|Boer, de|1927|p= 61}} The rolling mill was then re-equipped for rolling iron. In furnaces old iron and cast iron was made into [[Sheet metal]]. A [[Steam hammer]] of 1,200 kg then flattened the iron. It was cut up, made into slabs and finally rolled. In 24 hours 20,000 pounds of sheet metal could be produced. This iron rolling mill proved way to ambitious for the company. It made a loss of 3,000 guilders a week, and was immediately closed when the company was re-organized in 1870-1871.{{sfn|Boer, de|1927|p= 62}} |

The company ''Van Vlissingen en Co.'' then seems to have been incorporated into Van Vlissingen & Dudok van Heel in 1866.{{sfn|Boer, de|1927|p= 61}} The rolling mill was then re-equipped for rolling iron. In furnaces old iron and cast iron was made into [[Sheet metal]]. A [[Steam hammer]] of 1,200 kg then flattened the iron. It was cut up, made into slabs and finally rolled. In 24 hours 20,000 pounds of sheet metal could be produced. This iron rolling mill proved way to ambitious for the company. It made a loss of 3,000 guilders a week, and was immediately closed when the company was re-organized in 1870-1871.{{sfn|Boer, de|1927|p= 62}} |

||

==== The Moerdijk bridge ==== |

|||

[[File:NIMH_-_2011_-_0353_-_Aerial_photograph_of_Moerdijkbruggen,_The_Netherlands_-_1920_-_1940.jpg|thumb|The first railway bridge (foreground) at the Moerdijk in 1936]] |

|||

Van Vlissingen & Dudok van Heel also made iron bridges. When it had incorporated the rolling mill in the late 1860s, its failure to win the tender for the railway bridge at [[Culemborg]] was a big setback. |

|||

In order to ensure work for the rolling mill, the company then made an offer that was way too low in order to be sure to get the contract for the gigantic bridge over the [[Hollands Diep]]{{sfn|Boer, de|1927|p= 62}} The [[Moerdijk bridges|Moerdijk railway bridge]] was estimated at 2,350,000 guilders. The company made an offer of 1,466,740. It was so low that the minister asked whether a mistake had been made.{{sfn|Boer, de|1927|p= 63}} The bridge required 6,500,000 kg of metal, the iron coming from Amsterdam, and the steel and some other parts from England.{{sfn|Boer, de|1927|p= 63}} The company did think (or hope) that a clever engineering solution would make it possible to get the work done without loss, or perhaps only a small loss. In the end the bridge resulted in a loss of 225,695.97 guilders for the company{{sfn|Boer, de|1927|p= 73}}. Apart from that, the engineering was impressive. The bridge was the longest in Europe, and was opened on 1 January 1872, four months before the required date.{{sfn|Boer, de|1927|p= 73}} |

|||

=== Crisis of 1870 === |

=== Crisis of 1870 === |

||

Van Vlissingen & Dudok van Heel came into acute financial trouble in 1870 |

Van Vlissingen & Dudok van Heel came into acute financial trouble in 1870. In order to solve the problems the capital of the company was increased by a staggering 500,000 guilders in June 1870. The last installment of this sum was to be paid on 24 September 1870.<ref>{{Cite news |url=https://resolver.kb.nl/resolve?urn=MMHCO01:000065752:mpeg21:p003 | work = Provinciale Overijsselsche| title=Staten-Generaal| date=3 October 1870}}</ref> On 30 September 1870 the company then asked for an [[automatic stay]] so it would get time to reorganize its financial position, a step that led to wide disbelief and indignation.<ref>{{Cite news |url=https://resolver.kb.nl/resolve?urn=ddd:010098298:mpeg21:p002 | work = Algemeen Handelsblad | title=Amsterdam, Zaterdag 1 October| date=3 October 1870}}</ref> The reasons that the management gave were that many credit lines had been terminated, and payments had failed to come in because of the [[Franco-Prussian War]]. Furthermore that employees had been drafted. The resulting delays in the construction of the Stella for the KNSM had led to missing 135,000 guilders in payment terms.<ref>{{Cite news |url=https://resolver.kb.nl/resolve?urn=MMKB08:000115182:mpeg21:p001 | work = Delftsche courant | title=Delft, 4 October 1870| date=5 October 1870}}</ref> However, the primary cause of the troubles was the bad financial management of the company, that consistently took way too much money out of it. The automatic stay was granted by the court, and M.J. Pijnappel (lawyer), C. van der Vliet (creditor) and the famous engineer B.J. Tideman were appointed as administrators.<ref>{{Cite news |url=https://resolver.kb.nl/resolve?urn=ddd:010263176:mpeg21:p001 | work = De Tijd | title=Amsterdam, 8 October 1870| date=10 October 1870}}</ref> |

||

== Koninklijke Fabriek van Stoom- en andere Werktuigen == |

== Koninklijke Fabriek van Stoom- en andere Werktuigen == |

||

Revision as of 09:39, 25 October 2019

This article includes a list of references, related reading, or external links, but its sources remain unclear because it lacks inline citations. (October 2019) |

Werkspoor logo | |

Factory of Van Vlissingen and Dudok van Heel (to the right) in 1849 | |

| Industry | machines, rolling stock |

|---|---|

| Founded | 1827 |

| Founder | Paul van Vlissingen, Abraham Dudok van Heel |

| Defunct | 1989 |

| Headquarters | Amsterdam, Zuilen |

Werkspoor N.V. was the shortened, and later the official name of the Koninklijke Nederlandsche Fabriek van Werktuigen en Spoorwegmaterieel. It was a Dutch machine factory, known for rolling stock, (ship)steam engines, and diesel engines. The company was founded in 1827 by Paul van Vlissingen (1797-1876) and Abraham Dudok van Heel (1802-1873) with the support of William I of the Netherlands. Initially it was also a shipyard. In 1954 it was merged with Stork B.V..

Predecessors of Werkspoor

Werkspoor had two predecessors: the private company Van Vlissingen & Dudok van Heel and the public company Koninklijke Fabriek van Stoom- en andere Werktuigen.

Van Vlissingen & Dudok van Heel

The company was founded in Amsterdam on the island Oostenburg, previously owned by the Dutch East India Company. Its founder was Paul van Vlissingen, one of the founders of the Amsterdamse Stoombootmaatschappij. In 1826 he founded the 'Van Vlissingen' company as a shop to repair the steam engines of the Amsterdamse Stoombootmaatschappij. In 1827 a former smoking house of the Dutch East India Company was hired to expand the company.[1] In 1828 Abraham Dudok van Heel became a partner, and the name was changed to Fabriek van Stoom- en Andere Werktuigen, onder de firma Van Vlissingen & Dudok van Heel. (Factory for steam engines and other tooling, owned by Van Vlissingen & Dudok van Heel.) The 'onder firma' was Dutch for Kommanditgesellschaft a form of Limited partnership. In it General Partners Van Vlissingen and Dudok had a special claim to part of the profits.

Becomes a Royal factory

On 4 December 1840 the factory of Van Vlissingen & Dudok van Heel got the label 'royal', officially making it the: Koninklijke Fabriek van Stoom- en andere Werktuigen onder firma Van Vlissingen & Dudok van Heel.[2][3] In reality the company did not use the name 'Koninklijke Fabriek van Stoom- en andere Werktuigen' that often, and if it did, the name was almost always accompanied by: of Van Vlissingen & Dudok van Heel. A logical explanation would be that the 'firma Van Vlissingen & Dudok van Heel' was a Juridical person, a quality that the 'Koninklijke Fabriek' lacked. The succeeding 'Koninklijke Fabriek van Stoom- en andere Werktuigen' (below, without the 'firma' part) was a juridical person because it was the name of a public company.

Activities of Van Vlissingen & Dudok van Heel

In the 1850s Van Vlissingen & Dudok van Heel was the biggest machine factory of the Netherlands, with about 1,000 employees. It produced steam engines, steam boilers, and machinery for the sugar industry. From 1843-1846 it produced some steam locomotives. These were called the Etna, Hecla, Vesuvius, Atlas and Bromo. Some of these served till 1866.[3]

Ship engines

Steam ship engines were a core activity of the company. The company somewhat depended or was helped by government purchases. In turn the government depended on Van Vlissingen & Dudok van Heel as one of the few producers of steam engines. The state had shipyards, but no capacity to build engines. The close proximity of the Rijkswerf Amsterdam to the factory was also important. Van Vlissingen & Dudok van Heel made the 300 hp steam engines for HNLMS steam paddle vessel Gedeh[3]. It also made the 150 hp engine of the Sindoro.[4]

Steam engines for screw driven ships required a higher rotational speed. The company first made the engine of the Montrado (ex-Vuurpijl). The 150 hp engines of the corvette Amelia ex-Borneo (1855) came next. Those of HNLMS Adolf van Nassau (1861), and of at least two ships of the Djambi-class corvettes, launched 1860-1863 followed. The engines of the Watergeus-class sloops (1864-1867) and those of the Zilveren Kruis (1869) were engines that had an output that gave sailing ships something more than just auxiliary power.

For civilian use it made the engines for the Amicitia built by Fop Smit Nieuw Lekkerland in 1846.[5] It also built those of the steam yacht Rotterdam (1853), built by F. Smit in Kinderdijk for the service Rotterdam - 's-Hertogenbosch.[6]

Iron Ships

In 1844 Van Vlissingen traveled to Frankfurt, where he got an order for iron boats. In 1845 the company started building (iron) ships. For this activity a shipyard was created on Oostenburg north of the factory, where the shipyard of the old Dutch East India Company had been. The first two orders were for 4 tugboats and 26 iron lighters for German customers. Similar orders would follow for Italy and the Dutch East Indies.[7] In these years many iron ships were built, but not many large steam ships, apart from those were Van Vlissingen was also involved in the exploitation.

| Ship | Type | Launched | Length | Beam | Draught | Power | Notes |

|---|---|---|---|---|---|---|---|

| Main | Tugboat | 31 May 1845 | First tugboat built for the Frankfurt AG, steaming between Frankfurt and Biberich. [8] Left the yard 24 August 1845.[9] | ||||

| Frankfurt | Tugboat | 22 July 1845 | Second tugboat built for the Frankfurt AG, steaming between Frankfurt and Biberich.[10] | ||||

| Nieder Rhein I | Tugboat | 29 July 1846 | 200 hp | First tugboat for the Niederrheinische Dampfschleppschifffahrtsgesellschaft (Düsseldorf) [11] Left Amsterdam 16 March 1847.[12] | |||

| Pius IX | Tugboat | August 1847 | 150 feet | 22 feet | 60 cm | 2 * 50 hp | Built for service on the Po. Assembled by Cornelis van Vlissingen in Venice March - August[13] |

| Paul van Vlissingen | Tugboat | 19 Jan 1848 | For service between Amsterdam and the Upper Rhine by the Frankfurt AG.[14] | ||||

| Stoomvaart | Steam paddle ship | 8 August 1848 | For ASM line to Hamburg[15], the ninth steamship built.[16] | ||||

| 4th Frankfurt tugboat | Tugboat | 31 August 1848 | For service on the Main by the Frankfurt AG.[17] | ||||

| Gouverneur van Ewijck | Screw steam ship | 12 Nov 1848 | For the Stoom Schroef Schooner Maatschappij, Van Vlissingen participated in exploitation[15][18] | ||||

| Burgemeester Huydecoper | Screw steam ship | For the Stoom Schroef Schooner Maatschappij, Van Vlissingen participated in exploitation[15] | |||||

| Archimedes | Screw steam ship | 1849 | For tug services at Nieuwediep[19] | ||||

| Henriette | Schooner ship | 17 July 1851 | First sail ship built at the shipyard[20] First iron sea-going ship built in Amsterdam.[21] | ||||

| Eersteling | Screw steam ship | 17 July 1851 | For tug services on the [Noordhollandsch Kanaal]][22] | ||||

| Willem III | Steam ship | 26 January 1852 | For passenger service between Nijmegen and Arnhem[23] | ||||

| Prins van Oranje | Steam ship | 24 June 1852 | For service between Rotterdam and Dunkirk by the ASM under direction Paul van Vlissingen[24] | ||||

| Flevo | Steam ship | 5 July 1852 | For service between Amsterdam and Harlingen by the Friesche stoomboot-rederij[25] | ||||

| Hermine Marie Elisabeth | Barque | 20 December 1852 | 220 Last (unit), for Joh. Bletz and S.A.C. Dudok van Heel.[26] | ||||

| Johannes van Hartevelde | Screw steam Ship | 21 May 1853[27] | Built for the line Rotterdam - Gent.[28] | ||||

| Henriette Geertruida | Barque | 1853 | 200 last, laid down 20 December 1852[29] | ||||

| Düsseldorf No 3[30] | Tugboat | 1853 | 300 hp | ||||

| Vicenza | Tugboat | 1853 | 160 feet | 18 feet | 2 feet 3 dm | 100 | Assembled in Venice by J.P. Dudok van Heel.[31] |

| Tjitarum | Tugboat | 1853 | 140 feet | 20 feet | Assembled in Surabaya.[32] | ||

| Paramaribo | Screw steamship | 1853 | Built for the ministry of the colonies.[33] | ||||

| Two tugboats built for Egypt [34] | Tugboat | 1855 | 150 hp |

A breakthrough could have come from Belgium. In 1855 the steam ships Constitution and Belgique, 84.5 m long were launched.[35]

Rolling Mill at Het Funen

In 1855 Paul van Vlissingen founded a separate company Van Vlissingen en Co.. Its goal was to found a Rolling (metalworking) mill. The work was to seize the opportunity offered by a tender for re-coining copper currency that circulated in the Dutch East Indies. It asked for melting and re-coining 3,000,000 pounds of copper coins. Van Vlissingen en Co. got two-thirds of the tender. A rolling mill was then erected at 'Het Funen', an area just east of the existing buldings. The rolling mill was 168 feet long and 118 feet wide. The machinery was made by Van Vlissingen en Dudok van Heel. There were 12 annealing and smelt ovens, and 5 pairs of rolls.[36] In 1859 the re-coining operation had ended. The Rolling mill then got into deep trouble when it went to look for other work. The market for copper plate was in sharp decline because the shift to iron ships had reduced the demand for copper plate.[36]

The company Van Vlissingen en Co. then seems to have been incorporated into Van Vlissingen & Dudok van Heel in 1866.[36] The rolling mill was then re-equipped for rolling iron. In furnaces old iron and cast iron was made into Sheet metal. A Steam hammer of 1,200 kg then flattened the iron. It was cut up, made into slabs and finally rolled. In 24 hours 20,000 pounds of sheet metal could be produced. This iron rolling mill proved way to ambitious for the company. It made a loss of 3,000 guilders a week, and was immediately closed when the company was re-organized in 1870-1871.[37]

The Moerdijk bridge

Van Vlissingen & Dudok van Heel also made iron bridges. When it had incorporated the rolling mill in the late 1860s, its failure to win the tender for the railway bridge at Culemborg was a big setback.

In order to ensure work for the rolling mill, the company then made an offer that was way too low in order to be sure to get the contract for the gigantic bridge over the Hollands Diep[37] The Moerdijk railway bridge was estimated at 2,350,000 guilders. The company made an offer of 1,466,740. It was so low that the minister asked whether a mistake had been made.[38] The bridge required 6,500,000 kg of metal, the iron coming from Amsterdam, and the steel and some other parts from England.[38] The company did think (or hope) that a clever engineering solution would make it possible to get the work done without loss, or perhaps only a small loss. In the end the bridge resulted in a loss of 225,695.97 guilders for the company[39]. Apart from that, the engineering was impressive. The bridge was the longest in Europe, and was opened on 1 January 1872, four months before the required date.[39]

Crisis of 1870

Van Vlissingen & Dudok van Heel came into acute financial trouble in 1870. In order to solve the problems the capital of the company was increased by a staggering 500,000 guilders in June 1870. The last installment of this sum was to be paid on 24 September 1870.[40] On 30 September 1870 the company then asked for an automatic stay so it would get time to reorganize its financial position, a step that led to wide disbelief and indignation.[41] The reasons that the management gave were that many credit lines had been terminated, and payments had failed to come in because of the Franco-Prussian War. Furthermore that employees had been drafted. The resulting delays in the construction of the Stella for the KNSM had led to missing 135,000 guilders in payment terms.[42] However, the primary cause of the troubles was the bad financial management of the company, that consistently took way too much money out of it. The automatic stay was granted by the court, and M.J. Pijnappel (lawyer), C. van der Vliet (creditor) and the famous engineer B.J. Tideman were appointed as administrators.[43]

Koninklijke Fabriek van Stoom- en andere Werktuigen

The public company Koninklijke Fabriek van Stoom- en andere Werktuigen is founded

In mid October 1870 a meeting of the limited partners of the company was held. In this meeting the supervisory board declared that it had promoted the recent 500,000 guilders increase of capital in June, because it had been misled about 250,000 guilders being temporarily used for other purposes, and multiple tons of gold (100,000 guilders) in debts had been concealed from them.[44] General partner Van Vlissingen declared that both general partners were guilty of the many errors which had brought the company in its current position. Furthermore that they were prepared to renounce their privileged position and to cooperate in a reform of the limited partnership to a Naamloze vennootschap, a public company.[44] The meeting then appointed a committee of reorganization that would attempt to restructure the company as a public company.

In a meeting on 20 January 1871 the committee of reorganization made its report: All preferential creditors, and most of the normal creditors had agreed to their plans. 3 Creditors for a debt of 125,000 (out of the total debt of 1,250,000) refused to agree. The proposed settlement would consist of 40% payment in money, and 60% in 37-year bonds paying 3%, and later 5%. The commission had already found 300,000 guilders for securities, but did not want to proceed till all creditors agreed. The commission was then persuaded to continue for 3 more weeks in order to get the refusing creditors on board.[45]

In a 10 February 1871 meeting of the limited partners the committee of reorganization announced that the three refusing creditors had agreed to the proposals. Intervention by other creditors had led to this success. The commission then went to work on raising a short term credit of 200,000 guilders protected by special securities.[46] On 26 March 1871 the limited partners agreed to the final reorganization plan. The existing limited partnership was disbanded and all assets transferred[47] to a new public company. This public company came under the direction of Johannes Marinus van der Made and was founded[48] on 5 April. The government approval for the new public company came in a few weeks later. The new public company was allowed to retain the name Koninklijke Fabriek van Stoom- en andere Werktuigen, and this now came in general use.

Activities

The Koninklijke Fabriek got a lot of orders from the government. It made the machines for the monitor HNLMS Draak launched in 1877. It built the monitor Reinier Claeszen, laid down in 1890. It also started the construction of HNLMS Koningin Wilhelmina der Nederlanden. In about 1890 the Koninklijke Fabriek also got into trouble. HNLMS Koningin Wilhelmina had to be towed to the Rijkswerf in order to be finished there. The Koninklijke Fabriek would get two big successors: Werkspoor and NSM.

NSM (Ships)

When the Koninklijke Fabriek was restarted to later become Werkspoor, the shipbuilding activities were stopped. In 1893 former employees of the Koninklijke Fabriek then contacted Jacob Theodoor Cremer, and he founded the Nederlandsche Scheepsbouw Maatschappij (NSM) (literally: The Dutch shipbuilding company), a name that would later prove not to be an exaggeration. It used the terrain of the former shipyard of the Koninklijke Fabriek, but not the terrain of the engine factory, which was continued by Koninklijke Fabriek. Using the grounds and the former employees of the Koninklijke Fabriek, the NSM was a successor of the Koninklijke Fabriek, albeit only from an organizational perspective.

Werkspoor

In 1891 part of the Koninklijke Fabriek was saved and continued with financial support by machine factory Stork B.V. the new name became Nederlandsche Fabriek van Werktuigen en spoorwegmaterieel. (In Dutch: Dutch factory for tools and rolling stock).

In 1929 the telegraphy address Werkspoor would become the official name of the company. In 1954 Werkspoor was joined with Stork and became part of Verenigde Machinefabrieken Stork-Werkspoor (VMF).

Rolling stock

The manufacture of rolling stock was initially limited to railroad cars and the like. In 1897 a big order by the Netherlands–South African Railway Company for 40 locomotives and 400 cargo cars led to a breakthrough. It led to the construction of three big halls on Oostenburg designed by A.L. van Gendt. In 1913 the manufacture of railroad cars and steel constructions moved to Industrial park Lage Weide in Zuilen, now a suburb of Utrecht. A new factory complex for up to 6000 employees was built, and to house them the village Nieuw-Zuilen was founded which is now the city quarters Elinkwijk and De Lessepsbuurt. In Utrecht some famous bridges were built, like the Waalbrug in Nijmegen and the Bommelse Brug near Zaltbommel.

In the first years after World War 2 there was a lot of work to repair the Dutch railroad and tramway stock. Werkspoor also built a lot of new locomotives and carriages for the Dutch railroads. Orders were often shared with Beijnes in Haarlem and Allan of Rotterdam. With the independence of Indonesia Werkspoor lost a big market for its railway products. In 1951 this was temporarily compensated by a big order of 90 locomotives and 400 carriages from Argentina. It created work for seven years, and drove the number of employees to 5,000. By 1968 Werkspoor had so much work (e.g. plan V for the Dutch railways, and a big series of trams for Amsterdam), that it forwarded work to the German company DÜWAG. Nevertheless, the long term perspective for the rolling stock division was not bright, because it only delivered to the Dutch market. In 1972 the division was closed.

Machinery

Next to producing rolling stock, Werkspoor also remained active in machinery, and in particular ship engines. In 1910 it produced the first diesel engine for a sea-going ship, the Vulcanus, for the Bataafse Petroleum Maatschappij. In the early 20th century it also started to produce cooling machines in license from Linde AG. In 1960 a new big factory hall was built on the Amsterdam–Rhine Canal in Utrecht. It was to be used for the construction of large boilers and machines, the Apparatenhal, since 2013 known as Werkspoorkathedraal. In 1989 the engine division Stork-Werkspoor-Diesel (SWD) was bought by the Finnish company Wärtsilä.

Aircraft

Werkspoor was somewhat active in Dutch aeronautical industry. In 1925 it was involved in the construction of the first Dutch helicopter by Albert Gillis von Baumhauer. In 1930 KLM executive Albert Plesman ordered Werkspoor to create a cargoplane after a design by Joop Carley. The development of the Werkspoor Jumbo in cooperation with Pander & Son was plagued by the engine overheating. In 1931 the Jumbo made its first flight. The only specimen flew two years as a cargo plane for the KLM, and then seven years as a trainer. At the start of World War two the plane was lost in a bombardment.

Werkspoor worked as a subcontractor for Fokker in the late 1930s. By February 1939 500 of the 2,000 employees working for Fokker were working at the Werkspoor location Zuilen. These were woodworkers, that had been moved because there was not enough room for them in the rapidly expanding Fokker factory in Amsterdam.[49] The wings of the Fokker Fokker G.I, first flight 1937, were made of wood. The wings of the first G.I. were not built in Zuilen. Werkspoor did built wing parts for the Fokker G.I.[50]

In the 1950s the Netherlands, Belgium and the United States planned to build 460 Hawker Hunter fighter jets. In the context of a NATO plan part of this would be financed by America. The engines would be build by FN in Belgium. For constructing the airplane a consortium was founded.[51]

- Fokker: principal contractor, also responsible for final assembly of all the Dutch and part of the Belgian aircraft. Construction of the rear-part of the airframe.

- Werkspoor: construction of central part of the airframe[50]

- Aviolanda: construction of the front of the airframe

- Société Anonyme Belge de Constructiona Aéronautiques (Sabca): bouw van vleugels, construction of the wings and landing gear (license Dowty)

- Avions-Fairey: final assembly of part of the Belgian planes

Busses

Werkspoor built busses before and after World War Two. In the late 1940s 195 Crossley-busses were built for local public transport companies owned by the Nederlandse Spoorwegen. After that Werkspoor did not build any busses, but after seven years it re-entered the market by a request of the Nederlandse Spoorwegen, that wanted to prevent the big coachbuilder Verheul from gaining a monopoly. Verheul was able to build busses with a self-supporting body, and Nederlandse Spoorwegen thought that Werkspoor should also be able to do so. From 1956-1962 Nederlandse Spoorwegen and its subsidiaries received 477 Leyland-Werkspoor Bolramer busses. In 1962 Werkspoor sold the bus division to Hainje in Heerenveen, now part of VDL Groep.

Radio Telescope

In 1956 Werkspoor together with Philips, the Royal Netherlands Meteorological Institute and some Dutch universities built the Dwingeloo Radio Observatory.

Hyperbaric Chamber

In 1959 Werkspoor the first pressure chamber for hyperbaric medicine used for medical purposes. Customer was the Wilhelmina Gasthuis in Amsterdam. After the Wilhelmina Gasthuis became part of the Academic Medical Center in Amsterdam, the chamber moved to the Meibergdreef, where it is still used.

Nuclear reactor and ultracentrifuges

The first experiments with the use of ultracentrifuges for enriching uranium were executed by the Dutch physicist Dr. Jacob Kistemaker in the basements of Werkspoor in Amsterdam. This finally led to founding the uranium enrichment plant Urenco in Almelo in 1969. In the 1970s Werkspoor built the reactor pressure vessel for the KEMA Suspensie Test Reactor (KSTR), an experimental nuclear reactor used by KEMA in Arnhem from 1974-1979 for studies.

Legacy

In Amsterdam there was a Werkspoormuseum. Since 1950 it was housed the former ropewalk of the Dutch East Indies company. This 500 meter long building called Lijnbaan dates from 1660. The lower level had items from the Dutch East Indies company, the first floor treated the industrial heritage of Werkspoor. The museum was also a representative building for Stork, but was not open to the public, and was finally closed in 2011. Owner Stork then looked for a new place to house the collection in 2012.

On 12 September 2009 the Museum van Zuilen was opened on the de Amsterdamsestraatweg 569 in Utrecht, housing a Werkspoor-collection, focused on the Utrecht factory.

Rolling stock

An overview of rolling stock built by Werkspoor after World War Two. Ordered by customer.

Nederlandse Spoorwegen

Locomotives

- Locomotor NS Class 200/300 series (except 281-306) ('Sik')

- Diesel locomotives NS Class 400

- Diesel locomotives NS 450

- Diesel locomotives NS 2600

- Electrical locomotives NS Class 1000 together with SLM/Oerlikon Contraves

- Electrical locomotives NS Class 1200 together with Baldwin Locomotive Works/Westinghouse Electric Company

Trainsets

- Plan A (Mat '46) - together with Beijnes

- Plan B (Mat '46) - together with Allan and Beijnes

- Plan AB (Mat '46)

- Plan F (Mat '54) - together with Allan and Beijnes

- Plan G (Mat '54) - together with Allan

- Plan P (Mat '54)

- Plan Q (Mat '54)

- Benelux-trainsets (Mat '57)

- Plan U (Dieseldrieën)

- Plan X (Diesel-1 en 2) - Samen met Allan and Beijnes nickname: Blauwe Engelen

- Plan T (Mat '64)

- Plan V (Mat '64) Bouw t/m 1972 (treinstel 840). Daarna door Talbot

- Plan mP (Motorpost)

- SBB-CFF-FFS RAm TEE I and NS DE4 (Trans Europe Express, together with SBB)

Carriages

- Plan D - Together with Beijnes

- Plan E - Together with Beijnes

- Plan N

- Plan W

GVB (Amsterdam)

- Trams: Amsterdam drieasser-trams (numbers 491-550 and 951-1000).

- Trams: gelede wagens: Amsterdamse gelede trams (Beijnes/Werkspoor)|5G, 6G, 7G, numbers 653-669, 670-699 rear wagons by Düwag and 700-724.

HTM (Den Haag)

- Trams: serie 201-216 (1948, Haagse vierasser, nickname "Zwitsers")

RET (Rotterdam)

- Metrotype M|Metro: 5000-series.

- Trams: 300- and 600/1600-series.

Staatsmijnen

- Diesel locomotives DHB 450/500 (SM 171-183 (500 hp) and SM 191-196 (650 hp)

- Cargo cars: 2-axle zelflossers

Gallery of Werkspoor products

Miscellaneous

-

Steam engine in a sugar factory in Suriname.

-

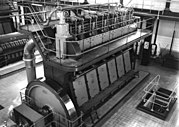

Stationary Werkspoor diesel engine.

-

Diesel engine Gemaal Cremer.

-

cast iron bascule_bridge built in 1906 across the Nieuwe Herengracht in Amsterdam.

Rolling stock

-

Steam locomotive NS 3301 (ex HSM 671).

-

Steam locomotive NS 3737 (ex SS] 731).

-

Railroad carriage SS C723.

-

Tram enginecar Nederlandsche Tramweg Maatschappij (NTM) C205.

-

Cat NTM K9.

-

Cargo car NTM E128.

-

Electrical locomotive NS_Class_1000.

-

Electrical locomotive NS_Class_1200.

-

Steam Locomotive Class B (0-6-4T) nr. 236 of NZASM

-

Electrical locomotive E518, South African Railways.

-

Locomotor NS 271.

-

Locomotor NS 362.

-

Diesel locomotive loc NS 451.

-

Diesel locomotive delivered to Argentina.

-

Railcar NS BC 1901.

-

Railcar NS BC 2901.

-

Dieseldrieën before delivery to NS on the Werkspoor terrain in 1934.

-

Dieseldrie NS 27.

-

Electric two car trainset NS 252.

-

streamlined post car NS Pec 8502.

-

five car diesel trainset in Geldermalsen.

-

Mat '46 electric two car trainset NS 273.

-

Mat '54 electric four car trainset NS 766.

-

Mat '57 Benelux train electric two car trainset in Antwerpen Centraal.

-

Motorcars for Dutch-Swiss TEE-trainset.

-

Diesel-Electric trainset NS Plan U.

-

Mat '64 electric two car trainset NS Plan V 419.

-

Mat '64 electric four car trainset NS Plan T 522.

-

Motorpost mP 3031.

-

Rotterdam Metro Metrotype M.

-

Blokkendoosrijtuig (Mat '24), steering car NS C 8104.

-

Rail carriage Plan D NS AB 7709.

-

Rail carriage Plan E NS C 6703.

-

Rail carriage Plan W, NS B 4118.

Trams

-

Tram motorcar 37 built 1908 for Gemeentetram Utrecht.

-

Motorcar 75 built 1927 for Gemeentetram Utrecht.

-

Motorcar 7 built 1909 for tram road Utrecht-Zeist.

-

Motorcar 84 built 1924 for tram road Amersfoort - Arnhem.

-

The Hague tramways motorcar 164 built 1907.

-

Haagse vierasser 215 built 1949.

-

Amsterdam drieasser 533 built 1950.

-

Amsterdamse dubbelgelede tram 660 (series 5G) built 1964.

-

Amsterdams dubbelgelede tram 724 (series 7G) built 1968.

-

RET motorwagen 520 bouwjaar 1931 (serie 511-550 gebouwd door Werkspoor).

-

Rotterdams Düwag tram nr. 608 built 1969.

References

- Boer, de, M.G. (1927), Honderd jaar machine-industrie op Oostenburg, Amsterdam, Druk de Bussy, Amsterdam

- Starink, D. (2014), "De Geschiedenis van de Nederlandse Vliegtuigindustrie 1914-2014" (PDF), Mars et Historia, Nederlandse Vereniging voor Militaire Historie

- H. de Jong: De locomotieven van Werkspoor. De Alk, Alkmaar, 1986. ISBN 90 6013 933 X

- W. van Scharenburg: Werkspoor Utrecht-Zuilen Deel I Trams en Treinen. ISBN 978-90-806997-5-5

- W. van Scharenburg: Werkspoor Utrecht-Zuilen Deel II Bruggen, Montage, Vrachtauto's, Boten, Bussen enz. ISBN 978-90-806997-6-2

Notes

- ^ Boer, de 1927, p. 7.

- ^ "Koninklijke Fabriek van Stoom- en andere Werktuigen". De avondbode. 10 December 1840.

- ^ a b c Boer, de 1927, p. 30.

- ^ "Berigten aan onze binnenlandsche dagbladen ontleend". N.R.C. 2 December 1846.

- ^ "Rotterdam, 18 junij". N.R.C. 19 June 1846.

- ^ "Kinderdijk, 1 April". Algemeen Handelsblad. 4 April 1853.

- ^ Boer, de 1927, p. 32.

- ^ "'s Gravenhage, den 1 junij". Dagblad van 's Gravenhage. 2 June 1845.

- ^ "Dingsdag 26 Augustus". Algemeen Handelsblad. 27 August 1845.

- ^ "Amsterdam, Dingsdag 22 Julij". Algemeen Handelsblad. 23 July 1845.

- ^ "Amsterdam, woensdag 29 Julij". Algemeen Handelsblad. 30 July 1846.

- ^ "Amsterdam, 16 Maart". Leydse courant. 22 March 1847.

- ^ "Amsterdam, 16 Maart". De Stoomvaar op de rivier de Po. 22 November 1847.

- ^ "Amsterdam, 19 januarij". Leydse courant. 21 January 1848.

- ^ a b c Boer, de 1927, p. 35.

- ^ "Amsterdam, woensdag 9 augustus". Algemeen Handelsblad. 10 August 1848.

- ^ "Binnenland". Algemeen Handelsblad. 1 September 1848.

- ^ "Rotterdam, 14 November". N.R.C. 15 November 1848.

- ^ "Amsterdam, Maandag 14 Januarij". Algemeen Handelsblad. 15 January 1850.

- ^ "Amsterdam, vrijdag 18 julij". Algemeen Handelsblad. 19 July 1851.

- ^ "Toestand der provincie Noord-Holland". Algemeen Handelsblad. 7 July 1852.

- ^ "Amsterdam, Dingsdag 12 Augustus". Algemeen Handelsblad. 13 August 1851.

- ^ "Amsterdam, Maandag 26 Januarij". Algemeen Handelsblad. 27 January 1852.

- ^ "Amsterdam, Donderdag 24 Junij". Algemeen Handelsblad. 25 June 1852.

- ^ "Rotterdam,5 Julij". N.R.C. 6 July 1852.

- ^ "Amsterdam, Maandag 20 December". Algemeen Handelsblad. 21 December 1852.

- ^ "Binnenland". N.R.C. 22 May 1853.

- ^ "Rotterdam, 7 Julij". Algemeen Handelsblad. 9 July 1853.

- ^ "Amsterdam, Maandag 20 December". Algemeen Handelsblad. 21 December 1852.

- ^ "Binnenland". De Grondwet. 10 September 1853.

- ^ "Italie". Leydse courant. 28 September 1853.

- ^ "Buitenland". Rotterdamsche courant. 30 September 1853.

- ^ "Binnenland". N.R.C. 30 October 1853.

- ^ "Binnenland". De constitutioneel: nieuwe 's-Gravenhaagsche courant. 1 October 1855.

- ^ Boer, de 1927, p. 38.

- ^ a b c Boer, de 1927, p. 61.

- ^ a b Boer, de 1927, p. 62.

- ^ a b Boer, de 1927, p. 63.

- ^ a b Boer, de 1927, p. 73.

- ^ "Staten-Generaal". Provinciale Overijsselsche. 3 October 1870.

- ^ "Amsterdam, Zaterdag 1 October". Algemeen Handelsblad. 3 October 1870.

- ^ "Delft, 4 October 1870". Delftsche courant. 5 October 1870.

- ^ "Amsterdam, 8 October 1870". De Tijd. 10 October 1870.

- ^ a b "Binnenlandsch Nieuws". Het nieuws van den dag. 18 October 1870.

- ^ "Binnenland". Algemeen Handelsblad. 22 January 1871.

- ^ "Amsterdam, Vrijdag 10 Februari". Algemeen Handelsblad. 12 February 1871.

- ^ "Bekendmaking". Nederlandsche staatscourant. 12 April 1871.

- ^ "Amsterdam, 26 Maart". De Tijd. 26 March 1871.

- ^ "Fokker werkt hard aan den bommenwerper T 9 voor Indië". Het Vaderland. 10 February 1939.

- ^ a b "Trots op Werkspoor" (PDF). De oud Utrechter. 18 September 2018.

- ^ Starink 2014, p. 17.

External links

- Museum van Zuilen: Has info on the Werkspoor factory in Utrecht (Zuilen)

- Langs de Rails: Many photos about Werkspoor rolling stock

- Werkspoor: Some photo's of Werkspoor in the 1950s

- Industriespoor: Diesel locomotives near the coal mines (DSM)

- Andere tijden: Treinen van Nederlandse bodem - geschiedenis24.nl

- Movie about the Werkspoormuseum

- Movie about assembling the NS Locomotive 1200 at Werkspoor 1950s

- Movie 100 jaar werkspoor in het hart van Zuilen"

![Steam locomotive NS 3737 (ex SS] 731).](/upwiki/wikipedia/commons/thumb/2/25/NS_3737_-_Bhv.jpg/197px-NS_3737_-_Bhv.jpg)