Pellet mill

A pellet mill, also known as a pellet press,[1] is a type of mill or machine press used to create pellets from powdered material. A wide range of pellets can be produced for animal or fish feed, fuel, fertilizer, manufacturing use or as a convenient way to store biomass or minerals.

Raw material, for example ground or crushed food, hard or soft wood, grass, paper, coal dust, iron ore, or organic matter is introduced into a hopper with around 15% water content. Here, other ingredients like vegetable oil, molasses or chemicals can be added to alter the components in the pellets and also the compression of the material through the die. Food materials first pass through a conditioner, which may include a steam heating or cooking process. Once in the compression chamber, a pair of rollers press and squeeze the material through a die containing holes of the required size (3mm - 20mm+). Pellets so produced can be bagged and stored. Pellet mills are unlike grinding mills, in that they combine small materials into a larger, homogeneous mass, rather than break large materials into smaller pieces.

Types

There are many types of pellet mills that can be generally grouped into large-scale and small-scale types. They are generally in two broad mechanical types;

- flat die - uses linear compression

- ring die - use compression through rollers over a die plate

Large-scale mills

There are two common types of large-scale pellet mills: flat die mills and ring die mills. Flat die mills use a flat die with slots. The powder is introduced to the top of the die and as the die rotates a roller presses the powder through the holes in the die. A cutter on the other side of the die cuts the exposed pellet free from the die.[1] In the ring die there are radial slot throughout the die. Powder is fed into the inside of the die and spreaders evenly distribute the powder. Two rollers then compress the powder through the die holes. Two cutters are used to cut the pellets free from the outside of the die.[2]

Large scale pellet mills are usually used to produce animal feed,[1] wood pellets, and fuel pellets for use in a pellet stove.

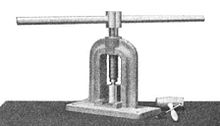

Small-scale mills

Small-scale mills are usually variations of screw presses or hydraulic presses. The same basic process is used for both types. A die, also known as a mold, holds the uncompressed powder in a shaped pocket. The pocket shape defined the final pellet shape. A platen is attached to the end of the screw (in a screw press) or the ram (in a hydraulic press) which compresses the powder.[3]

Some platens are heated to speed up the time it takes and improve the overall structure of the pellet. They may also have water ports for quick cooling between uses.[citation needed]

Applications

One of the more common applications is to produce KBr pellets which are used in infrared spectroscopy applications.

Animal feed pellets are usually a mixture of dry powdered feedstock, such as flour, sawdust, or grass, and a wet ingredient, such as molasses or steam. Feedstocks for pellet mills can sometimes break down and then re-form, or polymerize, under the extreme heat and pressure of the pellet mill.[citation needed]

Pellet Mill Project

Pellet Mill refers to a stand-alone equipment. It is the core machine of a complete production line of pellet. Therefore the Complete Line is called pellet plant or pellet complete production line. Generally, a pellet plant can either refer to a biomass pellet plant or an animal feed pellet plant due to the different use of pellets made with different ingredients. Pellet Mill is the forming equipment within a pellet plant, with the auxiliary equipment usually including crusher, hammer mill, mixer, cooler, sifter and packing machine.

References

- ^ a b c Pietsch, Wolfgang (2005), Agglomeration in Industry: Occurrence and Applications, vol. 1, Wiley-VCH, p. 254, ISBN 978-3-527-30582-7.

- ^ Matz, Samuel A. (1991), The chemistry and technology of cereals as food and feed (2nd ed.), Springer, p. 328, ISBN 978-0-442-30830-8.

- ^ Connecticut Agricultural Experiment Station (1898), Tenth Annual Report of the Storrs Agricultural Experiment Station, Storrs, Conn. 1897, Pelton & King, pp. 208–209.