Intumescent

An intumescent is a substance that swells as a result of heat exposure, thus leading to an increase in volume and decrease in density. Intumescents are typically used in passive fire protection and require listing, approval, and compliance in their installed configurations in order to comply with the national building codes and laws.[citation needed]

The details for individual building parts are specified in technical standards which are compiled and published by national or international standardization bodies like the British Standards Institute (BSI), the German Institute for Standardization (DIN), the American Society for Testing and Materials (ASTM) or the International Standardization Organization (ISO).

Intumescent coatings for steel constructions must be approved in standardized fire tests. Some important fire test standards are listed below:

- European Union: EN 13381-8 (Replaces national Standards in Europe)

- United Kingdom: BS 476-20/21 (Commonly referred to in EU, Middle and Far East)

- United States: ASTM E119 (Equivalent to UL 263, referred to in Middle and Far East), UL 1709 (Test using the hydrocarbon fire curve)

- Russia: VNIIPO (Also used in former Soviet Union countries)

- Chile: NCh 1974

- China: GB 14907/CNS 11728

- South Korea: KS F2257 1,6,7

- Taiwan: CNS 11728

Types

Soft char

These intumescents produce a light char, which is a poor conductor of heat, thus retarding heat transfer. Typically the light char consist of microporous carbonaceous foam formed by a chemical reaction of three main components: ammonium polyphosphate, pentaerythritol and melamine.[citation needed] The reaction takes place in a matrix formed by the molten binder which is typically based on vinyl acetate copolymers or styrene acrylates.

Ablative coatings contain a significant amount of hydrates. When the hydrates are heated, they decompose, and water vapour is released, which has a cooling effect. Once the water is spent, the insulation characteristics of the char that remains can slow down heat transfer from the exposed side to the unexposed side of an assembly.

Soft char products are typically used in thin film intumescents for fireproofing structural steel as well as in firestop pillows. Typically, the expansion pressure that is created for these products is very low, because the soft carbonaceous char has little substance, which is beneficial if the aim is to produce a layer of insulation.

Hard char

Harder chars are produced with sodium silicates and graphite. These products are suitable for use in plastic pipe firestops as well as exterior steel fireproofing. In those applications, it is necessary to produce a more substantial char capable of exerting quantifiable expansion pressure. In the case of firestops, a melting, burning plastic pipe must be squeezed together and shut so that there will be no opening for fire to propagate to an otherwise fire-resistance rated wall or floor assembly. In the case of exterior fireproofing, a hydrocarbon fire must be held off with quite potentially more kinetic energy than a house fire. Intumescents that produce hard chars are unsuitable for interior spray fireproofing.

Intumescent coatings

Intumescent coatings may be designed for protection of metals (primarily steel) from fire. They maybe based on a number of resin binders including epoxy, and silicone.[1] Melamine-formaldehyde resin systems have even been used using layered double-hydroxide modified phosphate esters that improved the intumescent properties and also made an improvement to the smoke suppression properties.[2]

Applications

Intumescents are used to achieve passive fire protection for such applications as firestopping, fireproofing, gasketing and window casings. Such applications are relevant for buildings, offshore constructions, ships and aircraft.

Problems

Some intumescents are susceptible to environmental influences, such as humidity, which can reduce or negate their ability to function. In Germany, the Deutsches Institut für Bautechnik, DIBt,[3] quantifies the ability of intumescents to stand the test of time against various environmental exposures. DIBt-approved firestops and fireproofing materials are available in Canada and the U.S.

Gallery

-

Low pressure intumescent resin: This product is suitable for use in passive fire protection in general, and in firestopping and interior fireproofing in particular. The small, orange chunk on the bottom right is capable of growing into the large black object above and to its left. This type of intumescent is typically highly endothermic and contains a considerable amount of chemically bound water in hydrates. As this is released, it cools adjacent materials. Such intumescents are useful as ingredients in firestop pillows and in paints used for fireproofing purposes. They do not produce enough expansion force to be used in plastic pipe devices, where the intumescent must squeeze shut a melting plastic pipe or conduit.

-

Pipe covered with a thin-film intumescent spray fireproofing commercial product called UniTherm. When the flame from a blow-torch is applied, the intumescent sodium silicate expands, forming a layer of insulation which slows heat transfer to the pipe underneath. Hydrates within the coating release their water content, maintaining a temperature near the boiling point of water, 100 °C. The critical steel temperature is ca. 540 °C. Once the water is consumed and sufficient heat has passed through the char, the steel can reach and exceed its critical temperature and lose its strength. The time this takes determines the fire-resistance rating.

-

In this picture, the flame has been removed after the thin-film intumescent spray fireproofing product has completely expanded. Some intumescents undergo shrinkage shortly after full expansion has taken place.

-

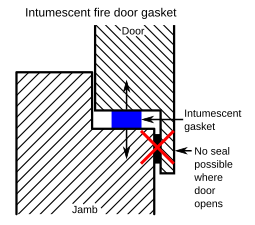

Intumescent gasketing used in passive fire protection, for fire door applications. Typically, such gasketing is needed to pass positive pressure furnace testing, a recent requirement in North America.

-

Intumescent putty, permanently pliable, used in a cable penetration firestop. These putties are similar in consistency to the play-dough used as children's toys. Putties of this nature also lend themselves to use as pads covering electrical outlet boxes inside drywall assemblies required to have a fire-resistance rating. The endothermic and insulative action of the pads reduce thermal transfer through the metallic outlet box to the unexposed side of the rated drywall assembly.

-

A passive fire protection example of an intumescent with strong expansion pressure. This intumescent is called Palusol. It is based on waterproofed sodium silicate. Another high-expansion intumescent popular for use in plastic pipe firestop devices is graphite. Graphite tends to be less affected by atmospheric conditions than many water-bearing intumescents.

-

Construction of a test sample consisting of a mock-up concrete floor frame, complete with penetrants. The concrete frame measures approximately 5’ x 9’ x 4" (ca. 1.5 m x 2.3 m x 10 cm). It has a large hole in the centre with many traversing mechanical and electrical services. The penetrants extend 1’ (30 cm) into the furnace and 3’ (91 cm) on the unexposed side. A firestop mortar is being applied here. Notice the intumescent wrap strip surrounding the fibreglass pipe insulation. When the fire starts, this embedded intumescent swells to take the place of the melting insulation. The test was conducted in accordance with the Canadian firestop test method ULC in Scarborough, Ontario.[4][full citation needed]

See also

References

- ^ Cardoso, de Sa, Beraldo, Hidalgo and Ferreira (November 2020). "Intumescent coatings using epoxy, alkyd, acrylic, silicone and silicone-epoxy hybrid resins for steel fire protection". Journal of Coatings Technology and Research. 17 (6): 1471–1488. doi:10.1007/s11998-020-00366-9.

{{cite journal}}: CS1 maint: multiple names: authors list (link) - ^ Xu, Deng and Lang (January 2020). "Flame retardancy and smoke suppression properties of transparent intumescent fire-retardant coatings reinforced with layered double hydroxides". Journal of Coatings Technology and Research. 17 (1): 157–169. doi:10.1007/s11998-019-00249-8.

- ^ DIBt (Deutsches Institut für Bautechnik), a state-level authority concerned with technical matters related to construction (building regulations, design, testing, certification, safety, building equipment, approvals, etc.

- ^ "S-115".

External links

- "The proof is in the fire" Chemical Innovation Magazine, American Chemical Society

- Article about intumescent materials

- Translation of DIBt test procedure for intumescent building products

- Translation of DIBt test procedure for reactive spray fireproofing materials

- American Chemical Society: Fire Retardancy of Polypropylene Composites Using Intumescent Coatings

- ASTM E 2786 - 2010 Standard Test Methods for Measuring Expansion of Intumescent Materials Used in Firestop and Joint Systems

![Construction of a test sample consisting of a mock-up concrete floor frame, complete with penetrants. The concrete frame measures approximately 5’ x 9’ x 4" (ca. 1.5 m x 2.3 m x 10 cm). It has a large hole in the centre with many traversing mechanical and electrical services. The penetrants extend 1’ (30 cm) into the furnace and 3’ (91 cm) on the unexposed side. A firestop mortar is being applied here. Notice the intumescent wrap strip surrounding the fibreglass pipe insulation. When the fire starts, this embedded intumescent swells to take the place of the melting insulation. The test was conducted in accordance with the Canadian firestop test method ULC in Scarborough, Ontario.[4][full citation needed]](/upwiki/wikipedia/commons/thumb/9/95/Ulc_prueflingsaufbau.jpg/340px-Ulc_prueflingsaufbau.jpg)