User:Chem538grp4w09/Sandbox

Shape Memory Polymers (SMPs) are polymeric smart materials which have the ability to return from a deformed state (temporary shape) to their original (permanent) shape induced by an external stimulus (trigger), such as e.g. temperature change.[1] Besides temperature change, as in the case of thermally activated SMPs, specific SMPs can also be triggered by an electric or magnetic field [2], light [3] or a change in pH. As well as polymers in general, SMP also cover a wide property-range from stable to biodegradable, from soft to hard and from elastic to rigid depending on the structural units that constitute the SMP. SMP include thermoplastic and thermoset (covalently cross-linked) polymeric materials. Shape memory polymers differ from shape memory alloys [4] by their glass transition or melting transition from a hard to a soft phase which is responsible for the shape memory effect. In shape memory alloys Martensitic/Austenitic transitions are responsible for the shape memory effect.

Properties of shape memory polymers

Besides temperature change, as in the case of thermally activated SMPs, specific SMPs can also be triggered by an electric or magnetic field [2], light [5] or a change in pH. As well as polymers in general, SMP also cover a wide property-range from stable to biodegradable, from soft to hard and from elastic to rigid depending on the structural units that constitute the SMP. SMP include thermoplastic and thermoset (covalently cross-linked) polymeric materials. Shape memory polymers differ from shape memory alloys [6] by their glass transition or melting transition from a hard to a soft phase which is responsible for the shape memory effect. In shape memory alloys Martensitic/Austenitic transitions are responsible for the shape memory effect.

Two important quantities that are used to describe shape memory effects are the strain recovery rate (Rr) and strain fixity rate (Rf). The strain recovery rate describes the ability of the material to memorize its permanent shape, while the strain fixity rate describes the ability of switching segments to fix the mechanical deformation.

File:Strainrecovery.jpg File:Strainfixity.jpg

where N is the cycle number, File:Maxstrain.jpg is the maximum strain imposed on the material, and File:Nstrain.jpg and File:Nstrain.jpg are the strains of the sample in to successive cycles in the stress-free state before yield stress is applied.

Shape memory effect can be described briefly as the following mathematical model.[7]

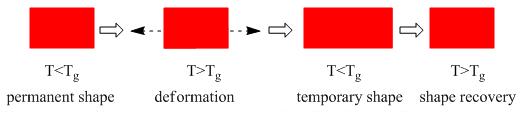

Description of the thermally induced shape memory effect

Polymers exhibiting a shape memory effect have both a visible, current (temporary) form and a stored (permanent) form. Once the latter has been manufactured by conventional methods, the material is changed into another, temporary form by processing through heating, deformation, and finally, cooling. The polymer maintains this temporary shape until the shape change into the permanent form is activated by a predetermined external stimulus. The secret behind these materials lies in their molecular network structure, which contains "switching segments" that have the ability to soften. Temperature increases past the glass transition temperature, File:Glasstrans.jpg, activates the switching: the soft switching segments, which are responsible for the temporary shape, soften and the material resumes its original (permanent) form. The hard to soft segment ratio is often between 5:95 and 95:5, but ideally this ratio is between 20:80 and 80:20[8]. The shape memory polymers are effectively visco-elastic [9] and many models and analysis methods exist.

Physically crosslinked SMPs

Linear Block Copolymers

Representative shape memory polymers in this category are polyurethanes, polyurethanes with ionic or mesogenic components made by prepolymer method. Other block copolymers also show the shape memory effect, such as, block copolymer of polyethyleneterephrhalate (PET) and polyethyleneoxide (PEO), block copolymers containing polystyrene and poly(1,4-butadiene), and an ABA triblock copolymer made from poly(2-methyl-2-oxazoline) and poly(Tetrahydrofuran).

Other thermoplastic polymers

A linear, amorphous polynorbornene (Norsorex, developed by CdF Chemie/Nippon Zeon) or organic-inorganic hybrid polymers consisting of polynorbornene units that are partially substituted by polyhedral oligosilsesquioxane (POSS) also have shape memory effect.

Chemically crosslinked SMPs

The main limitation of physically crosslinked polymers for the shape memory application is irreversible deformation during memory programming due to the creep. The network polymer can be synthesized by either polymerization with multifuctional (tri or higher functional) crosslinker or by subseqyent crosslinking of a linear or branched polymer.

Crosslinked polyurethane

This material can be made by using excess diisocyanate or by using a crosslinker such as glycerin, trimethylol propane. According to Buckley et al., introduction of covalent crosslinking improves in creep, increase in recovery temperature and recovery window. [10]

PEO based crosslinked SMPs

The PEO-PET block copolymers can be crosslinked by using maleic anhydride, glycerin or dimethyl 5-isopthalates as a crosslinking agent. The addition of 1.5 wt% maleic anhydride increased in shape recovery from 35% to 65% and tensile strength from 3 to 5 MPa.[11]

Light induced SMPs

Light activated shape memory polymers (LASMP) use processes of photo-crosslinking and photo-cleaving to change File:Glasstrans.jpg. Photo-crosslinking is achieved by using one wavelength of light, while a second wavelength of light reversibly cleaves the photo-crosslinked bonds. The effect achieved is that the material may be reversibly switched between an elastomer and a rigid polymer. Light does not change the temperature, only the cross-linking density within the material.[12]

Applications

Industrial applications

One of the first conceived industrial applications was in robotics [13] where shape memory (SM) foams were used to provide initial soft prehension in gripping. These SM foams could be subsequently hardened by cooling making a shape adaptive grip. Since this time the materials have seen widespread usage in e.g. the building industry (foam which expands with warmth to seal window frames), sports wear (helmets, judo and karate suits) and in some cases with thermochromic additives for ease of thermal profile observation. [14] Polyurethane SMPs are also applied as an autochoke element for engines.[15]

Potential medical applications

SMPs are smart materials with potential applications as, e.g., intravenous cannula,[15] self-adjusting orthodontic wires and selectively pliable tools for small scale surgical procedures where currently metal-based shape memory alloys such as Nitinol are widely used. Another application of SMP in the medical field could be its use in implants, e.g. minimally invasive (trough small incisions or natural orifices) implantation of a device in its small temporary shape which after activating the shape memory by e.g. temperature increase assumes its permanent (and mostly bulkier) shape. Certain classes of shape memory polymers possess an additional property: biodegradability. This offers the option to develop temporary implants. After the implant has fulfilled its intended use (e.g. healing/tissue regeneration has occurred), the material degrades into substances which can be eliminated by the body, thus allowing full functionality to be restored without the necessity for a second surgery to remove the implant in order to avoid long term negative effects (e.g. inflammation) . Examples of this development are e.g. vascular stents and surgical sutures (see for example www.mnemoscience.com). When used in surgical sutures, the shape memory property of SMPs enables wound closure with self-adjusting optimal tension, which avoids tissue damage due to too tight sutures and does support healing / regeneration. [16]

Potential industrial applications

Further potential applications include self-repairing structural components, such as e.g. automobile fenders in which dents are repaired by application of temperature.[17] After an undesired deformation, such as a dent in the fender, these materials "remember" their original shape. Heating them activates their "memory." In the example of the dent, the fender could be repaired with a heat source, such as a hair-dryer. The impact results in a temporary form, which changes back to the original form upon heating - in effect, the plastic repairs itself. SMPs may also be useful in the production of aircraft which would morph during flight. Currently, the Defense Advanced Research Projects Agency DARPA is testing wings which would change shape by 150%.[18]

Other potential applications

Some of the various other applications of SMPs includes clothing. For example, a shirt could be programmed to shorten sleeves[8] or increase the pore size of the clothing as temperature increases to increase breathability of the fabric and therefore regulate body temperature by increased ability of heat and water vapor to escape.[18]

News

The most recent developments are triple shape memory materials [19] which can store two shapes in memory.

External links

References

- ^ Lendlein, A., Kelch, S. Shape-memory polymers. Angew. Chem. Int. Ed. Engl. 41, 2034-2057 (2002).

- ^ a b Mohr, R. et al. Initiation of shape-memory effect by inductive heating of magnetic nanoparticles in thermoplastic polymers. Proc. Natl. Acad. Sci. U.S.A. 103, 3540-3545 (2006). Copyright (2006) National Academy of Sciences, U.S.A.

- ^ Lendlein, A. et al. Light-induced shape-memory polymers. Nature 434, 879-882 (2005).

- ^ Czichos H. Adolf Martens and the Research on Martensite. The Martensitic Transformation in Science and Technology (Ed. E. Hornbogen & N. Jost). pp 3–14, Informationsgesellschaft (1989).

- ^ Lendlein, A. et al. Light-induced shape-memory polymers. Nature 434, 879-882 (2005).

- ^ Czichos H. Adolf Martens and the Research on Martensite. The Martensitic Transformation in Science and Technology (Ed. E. Hornbogen & N. Jost). pp 3–14, Informationsgesellschaft (1989).

- ^ Kim B.K.; Lee S.Y.; Xu M. Polymer, 1996, 37, 5781

- ^ a b Shanmugasundaram, O.L.,"Shape Memory Polymers & their applications". The Indian Textile Journal. 04 Apr, 2009. http://www.indiantextilejournal.com/articles/FAdetails.asp?id=776

- ^ Tobushi. H., Hashimoto T., Hayashi S. & Yamada E. Thermomechanical Constitutive Modeling in Shape Memory Polymer of Polyurethane Series. Journal of Intelligent Material Systems and Structures. Vol 8, Technomic (August 1997).

- ^ Buckley CP.; Prisacariu C.; Caraculacu A. Polymer, 2007, 48, 1388

- ^ Park C.; Lee J.Y.; Chun B.C.; Chung Y.C.; Cho J.W.; Cho B.G. J. Appl Polym Sci., 2004, 94, 308

- ^ Havens, E., Snyder, E.A., Tong, T.H.,Light-activated shape memory polymers and associated applications, Proc. SPIE 5762, 48 (2005), DOI:10.1117/12.606109

- ^ Brennan, Mairin Chemical and Engineering News, 2001, 79, p. 5.

- ^ Monkman. G.J. & P.M. Taylor Memory Foams for Robot Grippers Robots in Unstructured Environments Proc. 5th Intl. Conf. on Advanced Robotics, pp. 339 342, Pisa, June 1991.

- ^ a b H. Tobushi et al. Sci. Technol. Adv. Mater. 9 (2008) 015009 "Shape recovery and irrecoverable strain control in polyurethane shape-memory polymer" free download

- ^ Lendlein, A., Langer, R.: Biodegradable, Elastic Shape Memory Polymers for Potential Biomedical Applications, Science 296, 1673-1675 (2002).

- ^ Monkman. G.J. - Advances in Shape Memory Polymer Actuation - Mechatronics - Vol 10, No. 4/5, pp. 489–498 - Pergamon June/August 2000.

- ^ a b Toensmeier, P.A.,"Shape memory polymers reshape product design". Plastics Engineering. FindArticles.com. 02 Apr, 2009. http://findarticles.com/p/articles/mi_hb6619/is_3_61/ai_n29164103/

- ^ Bellin, I., Kelch, S., Langer, R. & Lendlein, A. [1]. Proc. Natl. Acad. Sci. U.S.A. 103, 18043-18047 (2006. Copyright (2006) National Academy of Sciences, U.S.A.

Havens, E., Snyder, E.A., Tong, T.H.,Light-activated shape memory polymers and associated applications, Proc. SPIE 5762, 48 (2005), DOI:10.1117/12.606109