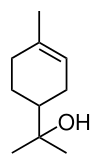

Terpineol

| |

| Names | |

|---|---|

| IUPAC name

2-(4-Methyl- 1-cyclohex- 3-enyl) propan- 2-ol

| |

| Other names

alpha-Terpineol

α-Terpineol p-Menth- 1-en-8-ol α,α,4- Trimethylcyclohex- 3-ene- 1-methanol Terpene alcohol | |

| Identifiers | |

3D model (JSmol)

|

|

| |

| Properties | |

| C10H18O | |

| Molar mass | 154.25 g/mol |

| Density | 0.9338 g/cm3 |

| Melting point | 39 °C |

| Boiling point | 219 °C 81-82 °C at 4.5 mmHg |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

| |

Terpineol is a naturally occurring monoterpene alcohol that has been isolated from a variety of sources such as cajuput oil, pine oil, and petitgrain oil[1]. There are three isomers, alpha-, beta-, and gamma-terpineol, the last two differing only by the location of the double bond. Terpineol is usually a mixture of these isomers with alpha-terpineol as the major constituent.

Terpineol has a pleasant odor similar to lilac and is a common ingredient in perfumes, cosmetics, and flavors. α-terpineol is one of the two most abundant aroma constituents of lapsang souchong tea; the α-terpineol originates in the pine smoke used to dry the tea.[2]

Although it is naturally occurring, terpineol is commonly manufactured from the more readily available alpha-pinene.

In one study an alternative route was demonstrated starting from d-limonene[3]:

Limonene is reacted with trifluoroacetic acid in a Markovnikov addition to a trifluoro acetate intermediate which is easily hydrolyzed with sodium hydroxide to α-terpineol with 76% selectivity. Side products are the β-terpineol in a mixture of cis-isomer and trans isomer and 4-terpineol.

References

- ^ Merck Index, 11th Edition, 9103.

- ^ Shan-Shan Yao; Wen-Fei Guo; YI Lu; Yuan-Xun Jiang, "Flavor Characteristics of Lapsang Souchong and Smoked Lapsang Souchong,a Special Chinese Black Tea with Pine Smoking Process", Journal of Agricultural and Food Chemistry, Vol. 53, No.22, (2005)

- ^ A Practical Synthesis of d--Terpineol via Markovnikov Addition of d-Limonene Using Trifluoroacetic Acid Yoshifumi Yuasa and Yoko Yuasa Org. Process Res. Dev.; 2006; 10(6) pp 1231 - 1232; (Article) doi:10.1021/op068012d