Boron carbide

| |

| Names | |

|---|---|

| IUPAC name

Boron carbide

| |

| Other names

Tetrabor

B4-C B4C Black Diamond | |

| Identifiers | |

3D model (JSmol)

|

|

| ChemSpider | |

| ECHA InfoCard | 100.031.907 |

PubChem CID

|

|

CompTox Dashboard (EPA)

|

|

| |

| |

| Properties | |

| B4C | |

| Molar mass | 55.255 g/mol |

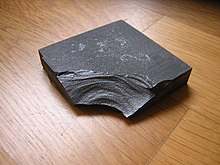

| Appearance | dark gray or black powder, odorless |

| Density | 2.52 g/cm3, solid. |

| Melting point | 2,350 °C (4,260 °F; 2,620 K) |

| Boiling point | 3,500 °C (6,330 °F; 3,770 K) |

| insoluble | |

| Acidity (pKa) | 6-7 (20 °C) |

| Structure | |

| Rhombohedral | |

| Hazards | |

| Occupational safety and health (OHS/OSH): | |

Main hazards

|

Harmful, irritant. |

| Related compounds | |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa).

| |

Boron carbide (chemical formula B4C) is an extremely hard ceramic material used in tank armor, bulletproof vests, and numerous industrial applications. With a hardness of 9.3 on the mohs scale, it is one of the hardest materials known, behind cubic boron nitride and diamond.

Boron carbide was discovered in the 19th century as a by-product of reactions involving metal borides, however, its chemical formula was unknown. It was not until the 1930s that the formula was determined to be B4C.[1] Boron carbide is now produced industrially by the carbothermal reduction of B2O3 (boron oxide) in an electric arc furnace.

Its ability to absorb neutrons without forming long lived radionuclides makes the material attractive as an absorbent for neutron radiation arising in nuclear power plants. Nuclear applications of boron carbide include shielding, control rod and shut down pellets. Within control rods, boron carbide is often powdered, to increase its surface area.

Uses

- Padlocks

- Personal and vehicle anti-ballistic armor plating.

- Grit blasting nozzles.

- High-pressure water jet cutter nozzles.

- Scratch and wear resistant coatings.

- Cutting tools and dies.

- Abrasives.

- Neutron absorber in nuclear reactors.

- Metal matrix composites.

- High energy fuel for solid fuel Ramjets.

Preparation

Boron carbide is prepared by reduction of boron trioxide either with carbon or magnesium in presence of carbon in an electric furnace at a temperature above 1400 °C. If magnesium is used, the reaction may be carried out in a graphite furnace and the magnesium byproducts are removed by treatment with acid.[2]

Notes

- ^ http://v3.espacenet.com/textdoc?DB=EPODOC&IDX=CA339873&F=0&QPN=CA339873

- ^ Pradyot Patnaik. Handbook of Inorganic Chemicals. McGraw-Hill, 2002, ISBN 0070494398

References

- Alan W. Weimer (1997). Carbide, Nitride and Boride Materials Synthesis and Processing. Chapman & Hall (London, New York). ISBN 0-412-54060-6.