Steam distillation

This article needs additional citations for verification. (August 2007) |

Steam distillation is a special type of distillation (a separation process) for temperature sensitive materials like natural aromatic compounds.

Many organic compounds tend to decompose at high sustained temperatures. Separation by normal distillation would then not be an option, so water or steam is introduced into the distillation apparatus. By adding water or steam, the boiling points of the compounds are depressed, allowing them to evaporate at lower temperatures, preferably below the temperatures at which the deterioration of the material becomes appreciable. If the substances to be distilled are very sensitive to heat, steam distillation can also be combined with vacuum distillation. After distillation the vapors are condensed as usual, usually yielding a two-phase system of water and the organic compounds, allowing for simple separation.

Principle[1]

When a mixture of two practically immiscible liquids is heated while being agitated to expose the surfaces of both the liquids to the vapor phase, each constituent independently exerts its own vapor pressure as a function of temperature as if the other constituent were not present. Consequently, the vapor pressure of the whole system increases. Boiling begins when the sum of the partial pressures of the two immiscible liquids just exceeds the atmospheric pressure (approximately 101 kPa at sea level). In this way, many organic compounds insoluble in water can be purified at a temperature well below the point at which decomposition occurs. For example, the boiling point of bromobenzene is 156 °C and the boiling point of water is 100 °C, but a mixture of the two boils at 95 °C. Thus, bromobenzene can be easily distilled at a temperature 61 C° below its normal boiling point.

Applications

Steam distillation is employed in the manufacture of essential oils, for instance, perfumes. In this method, steam is passed through the plant material containing the desired oils. It is also employed in the synthetic procedures of complex organic compounds. Eucalyptus oil and orange oil are obtained by this method on the industrial scale.

Steam distillation is also widely used in petroleum refineries and petrochemical plants where it is commonly referred to as "steam stripping".[2][3][4]

Other industrial uses of steam distillation include the production of consumer food products such as sprayable or aerosolized condiments such as sprayable mayonnaise.[5]

History

Steam distillation was invented by the Persian chemist, Ibn Sina (known as Avicenna in the West), in the early 11th century. He invented it for the purpose of extracting essential oils.[6]

The invention of steam distillation contributed significantly to the development of perfumery, in perfecting the extraction of fragrances. The steam distillation technology significantly influenced Western scientific developments. Many compounds could now be obtained in pure form, which was not possible beforehand.

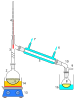

Equipment

This section needs expansion. You can help by adding to it. (August 2009) |

See also

- Azeotropic distillation

- Batch distillation

- Distillation

- Extractive distillation

- Fractional distillation

- Herbal distillates

- Laboratory equipment

- Steam engine

- Supercritical fluid extraction

- Theoretical plate

References

- ^ Martin's Physical Pharmacy & Pharmaceutical sciences, fifth edition, ISBN- 0-7817-6426-2, Lippincott williams & wilkins

- ^ Beychok, M.R., The Design of Sour Water Strippers, Individual Paper 61, Proceedings of Seventh World Petroleum Congress, Mexico City, April 1967

- ^ Kister, Henry Z. (1992). Distillation Design (1st Edition ed.). McGraw-Hill. ISBN 0-07-034909-6.

{{cite book}}:|edition=has extra text (help) - ^ Sour Water Steam Stripper Schematic Diagram

- ^ Purves, ER. (1972), Method for producing mayonnaise. U.S. Patent No. 3,804,957. Washington, DC: U.S. Patent and Trademark Office.

- ^ Marlene Ericksen (2000). Healing with Aromatherapy, p. 9. McGraw-Hill Professional. ISBN 0658003828.