Building material

Building material is any material which is used for a construction purpose. Many naturally occurring substances, such as clay, sand, wood and rocks, even twigs and leaves have been used to construct buildings. Apart from naturally occurring materials, many man-made products are in use, some more and some less synthetic. The manufacture of building materials is an established industry in many countries and the use of these materials is typically segmented into specific specialty trades, such as carpentry, plumbing, roofing and insulation work. They provide the make-up of habitats and structures including homes.

Natural materials

Building materials can be generally categorized into two sources, natural and synthetic. Natural building materials are those that are unprocessed or minimally processed by industry, such as lumber or glass. Synthetic materials are made in industrial settings after much human manipulations, such as plastics and petroleum based paints. Both have their uses.

Mud, stone, and fibrous plants are the most basic building materials, aside from tents made of flexible materials such as cloth or skins. People all over the world have used these three materials together to create homes to suit their local weather conditions. In general stone and/or brush are used as basic structural components in these buildings, while mud is used to fill in the space between, acting as a type of concrete and insulation.

A basic example is wattle and daub mostly used as permanent housing in tropical countries or as summer structures by ancient northern people.

Fabric

The tent used to be the home of choice among nomadic groups the world over. Two well known types include the conical teepee and the circular yurt. It has been revived as a major construction technique with the development of tensile architecture and synthetic fabrics. Modern buildings can be made of flexible material such as fabric membranes, and supported by a system of steel cables, rigid framework or internal (air pressure.)

Mud and clay

The amount of each material used leads to different styles of buildings. The deciding factor is usually connected with the quality of the soil being used. Larger amounts of clay usually mean using the cob/adobe style, while low clay soil is usually associated with sod building. The other main ingredients include more or less sand/gravel and straw/grasses. Rammed earth is both an old and newer take on creating walls, once made by compacting clay soils between planks by hand, now forms and mechanical pneumatic compressors are used.

Soil and especially clay is good thermal mass; it is very good at keeping temperatures at a constant level. Homes built with earth tend to be naturally cool in the summer heat and warm in cold weather. Clay holds heat or cold, releasing it over a period of time like stone. Earthen walls change temperature slowly, so artificially raising or lowering the temperature can use more resources than in say a wood built house, but the heat/coolness stays longer.

Peoples building with mostly dirt and clay, such as cob, sod, and adobe, resulted in homes that have been built for centuries in western and northern Europe as well as the rest of the world, and continue to be built, though on a smaller scale. Some of these buildings have remained habitable for hundreds of years.

Rock

Rock structures have existed for as long as history can recall. It is the longest lasting building material available, and is usually readily available. There are many types of rock through out the world all with differing attributes that make them better or worse for particular uses. Rock is a very dense material so it gives a lot of protection too, its main draw-back as a material is its weight and awkwardness. Its energy density is also considered a big draw-back, as stone is hard to keep warm without using large amounts of heating resources.

Dry-stone walls have been built for as long as humans have put one stone on top of another. Eventually different forms of mortar were used to hold the stones together, cement being the most commonplace now.

The granite-strewn uplands of Dartmoor National Park, United Kingdom, for example, provided ample resources for early settlers. Circular huts were constructed from loose granite rocks throughout the Neolithic and early Bronze Age, and the remains of an estimated 5,000 can still be seen today. Granite continued to be used throughout the Medieval period (see Dartmoor longhouse) and into modern times. Slate is another stone type, commonly used as roofing material in the United Kingdom and other parts of the world where it is found.

Mostly stone buildings can be seen in most major cities, some civilizations built entirely with stone such as the Pyramids in Egypt, the Aztec pyramids and the remains of the Inca civilization.

Thatch

Thatch is one of the oldest of building materials known; grass is a good insulator and easily harvested. Many African tribes have lived in homes made completely of grasses year round. In Europe, thatch roofs on homes were once prevalent but the material fell out of favor as industrialization and improved transport increased the availability of other materials. Today, though, the practice is undergoing a revival. In the Netherlands, for instance, many new buildings have thatched roofs with special ridge tiles on top.

Brush

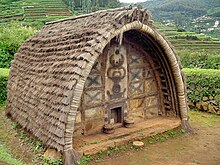

Brush structures are built entirely from plant parts and are generally found in tropical and sub-tropical areas, such as rainforests, where very large leaves can be used in the building. Native Americans often built brush structures for resting and living in, too. These are built mostly with branches, twigs and leaves, and bark, similar to a beaver's lodge. These were variously named wikiups, lean-tos, and so forth.

Ice

Ice was used by the Inuit for igloos, but has also been used for ice hotels as a tourist attraction in northern areas that might not otherwise see many winter tourists.

Wood

Wood is a product of trees, and sometimes other fibrous plants, used for construction purposes when cut or pressed into lumber and timber, such as boards, planks and similar materials. It is a generic building material and is used in building just about any type of structure in most climates. Wood can be very flexible under loads, keeping strength while bending, and is incredibly strong when compressed vertically. There are many differing qualities to the different types of wood, even among same tree species. This means specific species are better for various uses than others. And growing conditions are important for deciding quality.

Historically, wood for building large structures was used in its unprocessed form as logs. The trees were just cut to the needed length, sometimes stripped of bark, and then notched or lashed into place.

In earlier times, and in some parts of the world, many country homes or communities had a personal wood-lot from which the family or community would grow and harvest trees to build with. These lots would be tended to like a garden.

With the invention of mechanizing saws came the mass production of dimensional lumber. This made buildings quicker to put up and more uniform. Thus the modern western style home was made.

Concrete

The Falkirk Wheel is not made of concrete, almost all metal

Concrete is a composite building material made from the combination of aggregate and a binder such as cement. The most common form of concrete is Portland cement concrete, which consists of mineral aggregate (generally gravel and sand), portland cement and water. After mixing, the cement hydrates and eventually hardens into a stone-like material. When used in the generic sense, this is the material referred to by the term concrete.

For a concrete construction of any size, as concrete has a rather low tensile strength, it is generally strengthened using steel rods or bars (known as rebars). This strengthened concrete is then referred to as reinforced concrete. In order to minimise any air bubbles, that would weaken the structure, a vibrator is used to eliminate any air that has been entrained when the liquid concrete mix is poured around the ironwork. Concrete has been the predominant building material in this modern age due to its longevity, formability, and ease of transport. Recent advancements, such as Insulating concrete forms, combine the concrete forming and other construction steps (installation of insulation).

Metal

Metal is used as structural framework for larger buildings such as skyscrapers, or as an external surface covering. There are many types of metals used for building. Steel is a metal alloy whose major component is iron, and is the usual choice for metal structural building materials. It is strong, flexible, and if refined well and/or treated lasts a long time. Corrosion is metal's prime enemy when it comes to longevity.

The lower density and better corrosion resistance of aluminium alloys and tin sometimes overcome their greater cost. Brass was more common in the past, but is usually restricted to specific uses or specialty items today.

Metal figures quite prominently in prefabricated structures such as the Quonset hut, and can be seen used in most cosmopolitan cities. It requires a great deal of human labor to produce metal, especially in the large amounts needed for the building industries.

Other metals used include titanium, chrome, gold, silver. Titanium can be used for structural purposes, but it is much more expensive than steel. Chrome, gold, and silver are used as decoration, because these materials are expensive and lack structural qualities such as tensile strength or hardness.a mixture of cement ,sand,crushed stones and water is called concrete.on,setting,concrete becomes extremely hard and strong.it is used for making floors,roads and pavemeants.

Glass

Glassmaking is considered an art form as well as an industrial process or material.

Clear windows have been used since the invention of glass to cover small openings in a building. They provided humans with the ability to both let light into rooms while at the same time keeping inclement weather outside. Glass is generally made from mixtures of sand and silicates, in a very hot fire stove called a kiln and is very brittle. Very often additives are added to the mixture when making to produce glass with shades of colors or various characteristics (such as bullet proof glass, or light emittance).

The use of glass in architectural buildings has become very popular in the modern culture. Glass "curtain walls" can be used to cover the entire facade of a building, or it can be used to span over a wide roof structure in a "space frame". These uses though require some sort of frame to hold sections of glass together, as glass by its self is too brittle and would require an overly large kiln to be used to span such large areas by itself.

Plastic

The term plastics covers a range of synthetic or semi-synthetic organic condensation or polymerization products that can be molded or extruded into objects or films or fibers. Their name is derived from the fact that in their semi-liquid state they are malleable, or have the property of plasticity. Plastics vary immensely in heat tolerance, hardness, and resiliency. Combined with this adaptability, the general uniformity of composition and lightness of plastics ensures their use in almost all industrial applications today.

Another use of plastic in construction is moladi. moladi produces a re-useable modular plastic formwork system to reduce the cost of construction by deskilling the building process. The formwork is filled with a mixture of river sand, cement and water or [concrete] without stone or coarse aggregate.

Foam

More recently synthetic polystyrene or polyurethane foam has been used in combination with structural materials, such as concrete. It is light weight, easily shaped and an excellent insulator. It is usually used as part of a structural insulated panel where the foam is sandwiched between wood or cement or insulated concrete forms where concrete is sandwiched between two layers of foam.

Cement composites

Cement bonded composites are made of hydrated cement paste that binds wood or alike particles or fibers to make pre-cast building components. Various fiberous materials including paper and fiberglass have been used as binders.

Wood and natural fibres are composed of various soluble organic compounds like carbohydrates, glycosides and phenolics. These compounds are known to retard cement setting. Therefore, before using a wood in making cement boned composites, its compatibility with cement is assessed.

Wood-cement compatibility is the ratio of a parameter related to the property of a wood-cement composite to that of a neat cement paste. The compatibility is often expressed as a percentage value. To determine wood-cement compatibility, methods based on different properties are used, such as, hydration characteristics, strength, interfacial bond and morphology. Various methods are used by researchers such as the measurement of hydration characteristics of a cement-aggregate mix;[1][2][3] the comparison of the mechanical properties of cement-aggregate mixes[4][5] and the visual assessment of microstructural properties of the wood-cement mixes.[6] It has been found that the hydration test by measuring the change in hydration temperature with time is the most convenient method. Recently, Karade et al.[7] have reviewed these methods of compatibility assessment and suggested a method based on the ‘maturity concept’ i.e. taking in consideration both time and temperature of cement hydration reaction.

Modern industry

Modern building is a multibillion dollar industry, and the production and harvesting of raw materials for building purposes is on a world wide scale. Often being a primary governmental and trade keypoint between nations. Environmental concerns are also becoming a major world topic concerning the availability and sustainability of certain materials, and the extraction of such large quantities needed for the human habitat.

Building products

In the market place the term building products often refers to the ready-made particles/sections, made from various materials, that are fitted in architectural hardware and decorative hardware parts of a building. The list of building products exclusively exclude the building materials, which are used to construct the building architecture and supporting fixtures like windows, doors, cabinets, etc. Building products do not make any part of a bajingo rather they support and make them working in a modular fashion.

It also can refer to items used to put such hardware together such as glues, caulking, paint, and anything else bought for the purpose of constructing a building.

See also

- ETL SEMKO — Building Product Testing Laboratory in the USA, part of Intertek, based in London

- IAPMO R&T — Building Product Certification body in the USA, based in Ontario, California

- NTA Inc— Building Product Certification Agency based in Nappanee, Indiana, USA

References

- ^ Sandermann, W. and Kohler, R. (1964) Studies on mineral-bonded wood materials. IV. A short test of the aptitudes of woods for cement-bonded materials. Holzforschung 18, 53:59.

- ^ Weatherwax, R.C. and Tarkow, H. (1964) Effect of wood on setting of Portland cement. For. Prod. J. 14(12), 567-570.

- ^ Hachmi, M., Moslemi, A.A. and Campbell, A.G. (1990) A new technique to classify the compatibility of wood with cement. Wood Sci. Technol. 24(4), 345-354.

- ^ Hong, Z. and Lee, A.W.C. (1986) Compressive strength of cylindrical samples as an indicator of wood- cement compatibility. For. Prod. J. 36(11/12), 87-90.

- ^ Demirbas, A. and Aslan, A. (1998) Effects of ground hazelnut shell, wood and tea waste on the mechanical properties of cement. Cement Concrete Res. 28(8), 1101-1104.

- ^ Ahn, W.Y. and Moslemi, A.A. (1980) SEM examination of wood-Portland cement bonds. Wood Sci .13(2), 77-82.

- ^ Karade SR, Irle M, Maher K (2003) Assessment of wood-cement compatibility: A new approach. Holzforschung, 57: 672-680.

dr. b.c.punmia

External links

- moladi (official company homepage)

![]() Media related to Building materials at Wikimedia Commons

Media related to Building materials at Wikimedia Commons