Hartford City Glass Company

| |

| Company type | Corporation |

|---|---|

| Industry | Glass manufacturing |

| Founded | 1890 |

| Founder | Richard Heagany |

| Defunct | 1899 (facility continued to operate until 1929) |

| Fate | Purchased |

| Successor | Plant No. 3 of American Window Glass Company |

| Headquarters | |

Key people | Richard Heagany, J. R. Johnston |

| Products | window glass, chipped glass |

Number of employees | 550(1896) |

Hartford City Glass Company was once one of the largest manufacturers of window glass in the United States. The company existed in the 1890s during the peak of the Indiana Gas Boom, and employed over 500 people. The plant was located in Hartford City, Indiana—a city that was the home of eight glass factories by 1902. The firm was Hartford City's first glass factory, and became the city's largest manufacturer.

During the late 19th century, the window glass manufacturing process was labor-intensive and required highly-skilled glass blowers. Each glass-blower was assisted by a small crew of skilled and unskilled workers. Many of the skilled workers employed at the Hartford City Glass Company were from Belgium, which was the world’s leading manufacturer of window glass at the time. The Belgian workers and their families accounted for about one third of Hartford City's population during the 1890s, and their housing occupied most of the city's south side. For a few years, a local newspaper featured content written in French to attract the French-speaking Belgians.

In 1899, Hartford City Glass was acquired by the American Window Glass Company, which controlled 85 percent of the American window glass manufacturing capacity. During then next decade, the company began using machines to blow glass, and the Hartford City plant was one of the sites for testing and refinement of the new technology. The new process enabled the company to replace the well–paid glass blowers with unskilled machine operators, creating a manufacturing cost advantage. Hartford City’s American Window Glass plant began to employ fewer skilled workers, and many of the Belgian glass workers left town. During the 1920s, the company lost its cost advantage when competitors developed new processes for producing window glass. By the Great Depression, Hartford City’s American Window Glass plant, the former Hartford City Glass Company, was closed.

Indiana gas boom

During the late 1880s, the discovery of natural gas in Eaton, Indiana started an economic boom period in East Central Indiana.[1][2] Manufacturers were lured to the region to take advantage of the low cost fuel. Blackford County, a small rural county located close to Eaton, had only 181 people working in manufacturing in 1880. By 1901, the county had over 1,100 people employed at manufacturing plants in small communities such as Hartford City, Indiana.[3] Between 1880 and 1900, populations doubled in area counties such as Blackford, Delaware, and Grant.[4] The region became Indiana’s major manufacturing center.[5]

Hartford City

Like many East Central communities during the gas boom, Hartford City’s leaders sought to take advantage of their newfound energy resource. The Hartford City Land Company was formed in 1891 as part of the effort to attract manufacturers. The company offered "free sites, free gas, excellent switching facilities, and reasonable cash subsidies" as enticements for manufacturers to locate in the boom town.[6] Manufacturers that used high quantities of energy were especially attracted to no-cost or low-cost natural gas sites, and glassmaking was one of those energy-consuming industries.[7]

Hartford City was able to attract Richard Heagany (and what would become Hartford City Glass Company) in 1890, and Sneath Glass Company in 1894. During 1901, Indiana state inspectors visited 15 manufacturing facilities in Hartford City. These manufacturers employed 1,077 people, and the American Window Glass plant (the former Hartford City Glass Company) plus the Sneath Glass works accounted for over half of the manufacturing employees. By 1902, Hartford City was the home of 8 glass factories.[Note 1]

Organization and management

The Hartford City Glass Company was organized in 1890 to make window glass. Glassmaker Richard Heagany, with the financial assistance of several capitalists, organized the plant. Heagany was the plant's manager until his retirement in 1899.[9] Heagany had been superintendent of the largest window glass plant in New York, which he organized in 1878.[9] In 1886, he moved to Kokomo, Indiana, and organized the first window glass plant in the region to use natural gas as a fuel source. Heagany's Kokomo plant lasted three years before it was destroyed by fire. Instead of rebuilding, he moved to Hartford City.[9]

One of the principal stockholders of the new company was multi-millionaire A. M. Barber.[10] Barber was involved in grain and banking in Akron, Ohio.[11] Another important person from Akron was Colonel Arthur Latham Conger, who was the company's first president.[12] Conger was a Civil War veteran who invested in companies in Ohio and Indiana (including in Kokomo).[13] He was also elected president of the Hartford City Land Company in 1893.[14] S. W. Cantwell was secretary of the Hartford City Glass Company during its early years, and he was also president of the state organization of window glass manufacturers.[15] Cantwell was an attorney involved with the Blackford County Bank, Akron Oil Company, and Hartford City Land Company.[16]

Top management changed during 1895 after the company's annual shareholder's meeting. Colonel A. L. Conger, who had been president since the company's beginning, lost his position to another colonel from Akron, George T. Perkins. Conger had fallen into disfavor with many of the local citizens.[17] He immediately expressed his unhappiness with the election by selling his company stock and leaving town. Conger's stock was purchased by Kokomo banker John A. Jay.[18] Officers of Hartford City Glass in 1896 were: George T. Perkins, President; John A. Jay, Vice President; H.B. Smith, Treasurer; Richard Heagany, General Manager; and John Rodgers Johnston, Secretary.[19]

Colonel George Tod Perkins was a Civil War veteran and president of the B. F. Goodrich Company. He was also involved in banking, and had been president of the Bank of Akron.[13] H. B. Smith was president of the Citizen's Bank in Hartford City.[20] Johnston began working at the plant in 1890 as a bookkeeper, and was elected secretary after 4 years. He lived in Hartford City and helped Heagany run the business. Heagany submitted his resignation at the August 1899 board meeting, retiring after 42 years in the glass business. Johnston became plant manager at that time.[21] Johnston resigned a short time later, effective April 1900, and formed Hartford City's Johnston Glass Company in September of the same year.[22][23]

Workforce

The window glass manufacturing process used by Hartford City Glass was known as the Cylinder Method. Production crews were led by a glass-blower who was assisted by a small group of skilled and unskilled workers. The first step of the process involved the creation of a cylinder of glass by the glass–blower and his helper. Next, the cylinder was cut and flattened. Then the flat glass was cut into the desired size, and gradually cooled. The glass–blower and glass–cutter were highly skilled and well paid.[Note 2]

Skilled window glass–blowers were difficult to find. Belgium was the largest exporter of window glass to the United States, and plant manager Heagany had previously used the skills of glass-blowers from that country in his Kokomo glass works.[9] Therefore, it is not surprising that many of the glass-blowers at the Hartford City plant were from Belgium.[26]

The glass works was located on Hartford City's south side, and originally occupied 12 acres. To help meet the housing needs for the new factory's employees, 184 houses were built nearby.[19] During its peak years, the company employed 550 people. At one time, 443 workers at the plant lived in Hartford City, especially on the south side. Assuming each worker had a family of 5, over one third of the city's population was dependent upon Hartford City Glass.[19]

The city's influx of French-speaking Belgians had an impact on the town, and the south side (south of Lick Creek) became known as Belgium Town.[27] Since the religion of choice for most Belgians was Catholicism, it is no coincidence that the city's Catholic church remained on the south side.[28] The church's Father Dhe was a native of France, and was also involved with glass making.[29] During the early 1900s, the local Blackford County Gazette claimed to be the "only newspaper in State that prints French and circulates among the window glass and iron workers, the highest paid skilled mechanics in the world."[30]

The Belgian workforce also had an impact on the city's north side. Hartford City's Presbyterian Church, which is now part of the National Register of Historical Places, was built one block north of the courthouse in 1894—and features large stained glass windows imported from Belgium.[31] For over 50 years, the bigger of two huge windows was considered the largest single-frame window in the state of Indiana.[32] These stained-glass windows, plus at least four smaller ones, were installed by the local (and mostly Catholic) Belgian glass workers.[31]

Infrastructure

Construction of Hartford City's new glass works was completed in early January 1891, and production started shortly thereafter. With a capacity of 30 pots, the plant was thought to be the largest window glass plant in the world.[33][34] This was more than double the capacity of some of the window glass plants built a few years earlier in Ohio.[Note 3]

In Hartford City, natural gas was utilized as the fuel source for melting the raw materials into molten glass and for a gradual cooling process (annealing) necessary to prevent the glass from breaking. Initial production continued until June, when the works was shut down to decrease inventories.[37] Summer shutdowns at glass factories were normal because the extreme heat caused by glassmaking, combined with warm summer temperatures, could make working conditions almost unbearable. Since the worst working conditions were in the summer months, shutdowns for maintenance (or for manipulation of inventories) generally occurred during the hottest days of the summer. In the case of the first year's shutdown for the Hartford City Glass works, production was restarted in October.[38]

The plant's capacity was increased twice in the next two years.[Note 4] In 1892, management decided to expand the factory's capacity by 50 pots.[40] The expansion enlarged capacity to 90 pots, and made the works the second-largest glass factory in the United States. Expenditures necessary to finance the expansion were $100,000.[41] Capacity was increased again in 1893. This time, a tank with the capacity equivalent to 60 pots was added.[Note 5] This expansion cost $150,000, and was said to "give employment to 350 men."[43] By September, the plant had a payroll of $45,000 per month, and employed 500 glass workers.[44]

The summer shutdown for 1895 was during July and August. By that time, the glass works was using two tanks, which were equal to 100 pots in capacity.[45] By 1896, the plant employed 550 people, and produced about 2 million square feet of window glass per month.[46] The plant was the second-largest window glass plant in the country, and the largest producer of chipped glass. The plant grounds covered 25 acres, and had its own railroad spur off of the Pennsylvania Railroad. The grounds contained two melting rooms, two warehouses, a blacksmith shop, and a machine shop. The tank in one of the melting rooms was 85 feet long, 18 feet wide, and 6 feet deep. One tank required 4 flattening ovens and a cutting room.[46] Plans for another expansion began in late 1896. At that time, the plant was the third-largest window glass plant in the United States. A third tank was planned, which would make the Hartford City plant the largest in the country.[47] However, ownership was not satisfied with the concessions requested of the city, and the expansion was never consummated.[Note 6]

Acquisition

During the first half of 1899, work proceeded to organize a glass trust called American Window Glass Company. The plan was for the trust to acquire 70 glass plants, "some of which it will close to bring the production down to the demand."[50] Owners of the glass plants that were to be acquired could sell their plant for either cash or a combination of cash and stock in the new company.[51]

The trust was incorporated effective August 2, 1899. James A. Chambers was president.[52] Initial acquisitions included over 20 major window glass plants, including Hartford City Glass Company. Most of the original acquisitions were from Indiana and Pennsylvania, and those glass plants were important enough to enable American Window Glass to control 85 percent of the window glass production in the United States.[Note 7] Hartford City’s H.B. Smith was one of the directors of the newly incorporated company.[52] The Hartford City Glass Company became known as Plant Number 3 of the American Window Glass Company.[53] J. R. Johnston was named manager in December.[54] Hartford City's Hurrle Glass Company was also acquired by the trust.[50]

During the spring of 1900, rumors circulated that American Window Glass planned to move production from smaller plants in nearby Dunkirk and Redkey (factories 17, 30, 34, and 41) to the large southside Hartford City plant. If the Hartford City plant would have its capacity expanded equal to the capacity of the two plants to be consolidated, then Hartford City "will become the greatest window glass town in the world."[55] The plant would employ nearly 1000 people, and equal the largest window glass plant in the world in capacity. That plant in combination with Hartford City's two other window glass factories, and not even considering the flint glass plants or bottle plants, would make the city's window glass capacity the highest in the world.[55] However, the southside plant was not expanded, and continued to have a capacity of 104 pots—making it the third largest window glass plant in the United States.

Plant number 3

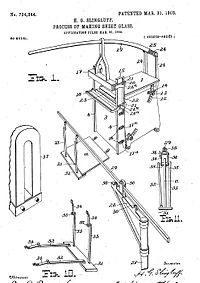

After the acquisition, the Hartford City Glass works became known as plant number 3 of the American Window Glass Company. The plant employed 450 people in 1901.[3] As natural gas supplies in Indiana became depleted, many manufacturers moved or did not survive.[56] The major plants of the American Window Glass successfully changed energy sources from natural gas to gas made from coal.[57] The company also had a technological advantage. American Window Glass plants used a machine, known as the Lubbers blowing machine, although it was not immediately utilized at all plants. The glass blowing machine was created by Pittsburgh resident John H. Lubbers, and he continued to contribute to improvements for the machine over the next decade.[58] Refinements to the process and machine were also made by Harry G. Slingluff, manager of the Hartford City plant where significant testing transpired. Production records for the entire company were set at the Hartford City plant in 1905, and 1907, using the Lubbers machines.[59][60]

By using the Lubbers machine, human glass blowers were replaced with a machine operator paid 30 percent of the glass blower wage. The machine was also five times more productive than the human blowers, and could make windows four times as large.[61][60] Thus, the highest–paid skilled workers in the United States were considered obsolete. In the case of Hartford City, machines replaced most of the human glass blowers by 1908.[62] By 1910, plant number 3 employed 500 people, but plant number 32 had been closed. The glass blowing machine, combined with difficulty returning from summer vacations in their European homeland after the start of World War I, caused a drastic reduction in the Belgian portion of Hartford City's glassmaking workforce.[63]

In 1913, American Window Glass was still the dominant window glass manufacturer, and accounted for over half of the nation's window glass manufacturing capacity.[61] The company was closing many of its smaller plants, while the large plants were equipped with the glass blowing machines. Plant number 3 was the third largest window glass factory in the United States, and the largest west of Pennsylvania.[61]

American Window Glass made record profits in 1920. All of the company's small plants had been sold or closed by that time, and the glass-blowing machines were still being used. The company was described as having "six large and well-equipped plants located near the Pittsburgh district, and one large plant at Hartford City, Ind."[64]

Decline

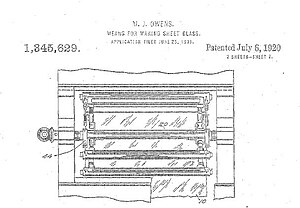

The machines used by American Window Glass replaced glass blowers, but still used the same blowing and cutting process used in the 1880s—although the company was constantly working to make the process more efficient. American inventor Irving W. Colburn began working on a machine that produced window glass using a different process, and received patents during the first decade of the 20th century. Colburn filed for bankruptcy in 1912, but his patents were purchased by Edward Drummond Libbey and Michael J. Owens—who hired Colburn to continue work on the machine.[65] Owens was the creator of the Owens Bottling Machine that revolutionized the glass bottle industry.[66][67] Working with Colburn, Owens helped improve the window glass machine, and it began being used for production in 1921. By 1926, Libbey-Owens had gained a market share of 29 percent, and American Window Glass's share was 59 percent. During the 1920s, Pittsburgh Plate Glass also developed a new process for making window glass, creating even more competition in the window glass industry.[65][Note 8]

Because of the improved technology and processes utilized by competitors, many of the American Window Glass patents, and much of its machinery, became obsolete. By the late 1920s, American Window Glass was forced to begin re-equipping its plants with new machinery. The company underwent a financial reorganization in 1929, and cut dividends on its preferred stock. Although a few plants were re-equipped, the Hartford City plant was not.[68]

Hartford City's natural gas supply was depleted, and the type of sand used to produce glass was in better supply near other American Window Glass plants in Pennsylvania. Thus, American Window Glass Company plant number 3, the former Hartford City Glass Company, was closed in 1929.[25]

Notes and references

- Notes

- ^ Dale lists 7 glass factories in Hartford City in 1902: American Window Glass Company factory number 3, American Window Glass Company factory number 32, Blackford Glass Company, Clelland Glass Company, Diamond Flint Glass Company, Johnston Glass Company, Hartford City Flint Glass Company, and Sneath Glass Company. [8] The Sans-Pariel Bottle Company is listed in a 1901 inspection report. [3]

- ^ Paquette discusses window glassmaking during the 1880s in an appendix to his book.[24] Window glassmaking at the Hartford City Glass Company plant is discussed, by a former glassworker who's father worked at the Hartford City plant, in a book produced by the Blackford County Historical Society.[25]

- ^ The first window glass plant built in Fostoria, Ohio, (Mambourg Glass Company built in 1887) had a capacity of 13 pots.[35] In Toledo, Ohio, the Toledo Window Glass Company plant was built in 1888, and had a 10 pot capacity.[36]

- ^ Capacity "expansion" was difficult to measure precisely, as tanks sometimes replaced pot furnaces instead of solely adding to capacity. The pot-equivalency of a tank varied, depending on the tank size and way the tank was equipped.[39]

- ^ At that time, two types of furnaces were used to create the molten glass. The older type was a pot furnace, where ceramic pots were heated inside the furnace to melt the batch of ingredients needed to make the molten glass. The newer type of furnace used a large brick tank that could be operated continuously or by the batch.[42]

- ^ Testimony before the United States House Committee on Ways and Means in 1913 listed the Hartford City Glass Company as having two tanks in 1898—not three.[48] In 1913, when the plant was owned by American Window Glass Company, it was still described as having two tanks: a large tank "equipped with 10 machines" and a "smaller tank, with a six-machine equipment".[49]

- ^ Many of the Indiana glass works acquired by the American Window Glass Company trust were from the East Central Indiana Gas Belt. Among those plants were the Hartford City Glass Company, and the Muncie plants of Maring, Hart, and Company and C. H. Over. Other plants were located in Anderson, Dunkirk, and Fairmount, Indiana.[52]

- ^ Competition in the window glass industry increased more in the 1930s. During the early 1900s, a Belgian named Emil Fourcault developed a more mechanized method (Fourcault process) to produce window glass. This process was adopted during the 1930s by a group of companies in the United States called Furco Glass. Market share for American Window Glass fell to 20 percent in the United States. The remainder of the market was dominated by three other manufacturers: Libbey-Owens with 30 percent, Pittsburgh Plate Glass with 25 percent, and Furco with 25 percent.[65]

- References

- ^ "Indiana's Natural Gas Boom". The American Oil & Gas Historical Society. Retrieved 2013-02-17.

- ^ Glass & Kohrman 2005, p. 10

- ^ a b c Indiana Department of Inspection 1902, p. 57

- ^ Forstall 1996, pp. 49–53

- ^ Glass & Kohrman 2005, p. 7

- ^ Unlisted (Hartford City Illustrated) 1896, p. 4

- ^ Hamilton, Kent & Lankford 2005, p. 13 section 8

- ^ Dale 1902, pp. 121–122

- ^ a b c d "Factory Owner of Natural Gas Days Here Dies". Kokomo Daily Tribune. 1925-09-25. p. 1.

In 1890, Mr. Heagany want to Hartford City, where he organized the Hartford City Glass company….

- ^ Unlisted (Glass & Pottery World) 1896, p. 10

- ^ Graham & Perrin (editor) 1881, p. 684

- ^ Unlisted (Paint, Oil and Drug Review) 1899, p. 13

- ^ a b Lane 1892, p. 470 Cite error: The named reference "Lane470" was defined multiple times with different content (see the help page).

- ^ "Indiana State News". Parker News. 1893-09-08. p. 7.

Col. A. L. Conger continues president. Col. Conger has also been elected president of the Hartford City Land Company.

- ^ "Within Our Borders - Will Make No Glass". Goshen Daily News. 1891-09-01. p. 3.

- ^ Unlisted (Hartford City Illustrated) 1896, p. 30

- ^ "Dont Bet on the Colonel". Hartford City Telegram. 1894-12-12. p. 1.

Well, Hartford City has realized some of its dreams, but it was in spite of Colonel Conger; and the people who once patted themselves on the back out of the satisfaction afforded by the colonel's palaver are now kicking themselves in another place for having been taken in.

{{cite news}}: line feed character in|quote=at position 33 (help) - ^ "Col. Conger Beaten". Fort Wayne Weekly Gazette. 1895-09-05. p. 2.

In a fit of rage the colonel offered his stock for sale, and it was gobbled up on the spot by John A. Jay, of Kokomo, who paid $28,750 cash for it. Col. Conger departed for Muncie an angry and disappointed man.

- ^ a b c Unlisted (Hartford City Illustrated) 1896, p. 18

- ^ Unlisted (Hartford City Illustrated) 1896, p. 15

- ^ "Annual Meetings. Manufacturers Directors of the Hartford City Glass Company and Hartford City Land Company Meet". Hartford City Telegram. 1899-08-30. p. 1.

The only change made in the officers results from the resignation of Richard Heagany as manager. Mr. Heagany's duties hereafter will fall upon Secretary Johnston.

- ^ Fleming & American Historical Society 1923, p. 39

- ^ Castelo et al. 2012, p. 35

- ^ Paquette 2002, pp. 469–475

- ^ a b Castelo et al. 2012, pp. 16–17

- ^ Clamme & Castelo 2011, p. 11

- ^ Blackford County Historical Society (Ind.) 1986, pp. 48–49

- ^ Blackford County Historical Society (Ind.) 1986, p. 68

- ^ Clamme & Castelo 2011, p. 23

- ^ Blackford County Gazette (advertisement) 1903, p. 269

- ^ a b Blackford County Historical Society (Ind.) 1986, p. 67

- ^ Amstutz 1947, p. 7

- ^ "(column on far left)". Rochester Tribune. 1891-01-02. p. 1.

The Hartford City glass works have just been completed and are said to be the largest and best arranged window glass works in the world.

- ^ "(third column from left)". Hartford City Telegram. 1893-03-02. p. 1.

The capacity of the original factory here was 30 pots, 60 more were added by the completion of the new tank and this number with the 80 pot, which is all in the mind at this writing, would make a 170 pot factory which would furnish employment to near 900 persons.

- ^ Paquette 2002, p. 176

- ^ Paquette 2002, pp. 333–334

- ^ "State News - Glass Works Shut Down". Goshen Daily News. 1891-06-03. p. 5.

- ^ "Over the State". Logansport Journal. 1891-10-07. p. 3.

The Hartford City glass works have resumed operations.

{{cite news}}: line feed character in|quote=at position 35 (help) - ^ Merriam et al. 1901, p. 390

- ^ "Indiana State News". Spencer Democrat. 1892-04-07. p. 6.

- ^ "Glass Works for Hartford City". Connersville Daily Examiner. 1892-03-31. p. 1.

- ^ United States Bureau of foreign and domestic commerce (Dept. of Commerce) 1917, p. 41

- ^ "State News Summary". Shoals Martin County Tribune. 1893-03-24. p. 2.

- ^ "From Hoosierdom - Glass Works to Start". Logansport Reporter. 1893-09-20. p. 1.

- ^ "Glass Works Closed". Hamilton Daily Republican. 1895-07-02. p. 1.

- ^ a b Unlisted (Hartford City Illustrated) 1896, p. 16

- ^ "Indiana News - Enlarging a Glass Plant". Connersville Daily Examiner. 1896-12-28. p. 1.

The Hartford City plant is already the third largest plant in America, and when this is completed it will surpass, any in point of capacity in the country.

- ^ United States Congress House Committee on Ways and Means 1913, p. 406

- ^ Unlisted (National Glass Budget) 1913, p. 7

- ^ a b "The Big Trust. The New Window Glass Combine Certain". Hartford City Telegram. 1899-05-17. p. 1.

It is announced that the $30,000,000 window glass trust is a certainty. The work of organization is now in progress and the new concern will be ready to take the place of the window glass combine known as the American Glass company on the last day of this month, when the fires go out of all the factories for this season. It is said that the trust will control 93 percent of the productive capacity of the country. The trust will be called the American Window Glass company.

- ^ "The Glass Trust. Manufacturers Believe It Is a Sure Go". Hartford City Telegram. 1899-07-12. p. 1.

The manufacturers who are selling their plants to the trust at prices which must astonish even themselves have the choice of taking cash or part cash and stock for their property. Most of them are taking some of the stock. Much of the stock will be held in Hartford City.

- ^ a b c Wallace 1901, p. 315

- ^ Unlisted (Paint, Oil and Drug Review) 1907, p. 4

- ^ "(second column from right, near bottom of page)". Hartford City Telegram. 1899-12-13. p. 1.

The American Window Glass company's factories in this section will be managed as follows: J. R. Johnston will manage factory No. 3 in this city;….

- ^ a b "We'll Lead the World". Portland Semi Weekly Sun. 1900-05-22. p. 1.

The statement in yesterday's Times to the effect that a report was current that the American Window Glass company expects to move its Redkey and Dunkirk plants to Hartford City, was the subject of considerable comment. If the report is true and the project is carried out, Hartford City will become the greatest window glass town in the world.

- ^ Glass & Kohrman 2005, p. 91

- ^ "American Window Glass is to Continue the Use of Coal Gas". Hartford City Telegram. 1895-09-27. p. 1.

It is the intention to continue the use of coal gas until such time as some cheaper fuel may be evolved.

- ^ Unlisted (National Glass Budget) 1917, p. 1

- ^ "Indiana Company Has New Glass Making Record". Fort Wayne Journal Gazette. 1905-04-09. p. 18.

The American Window Glass company's No. 3 plant on the south side in this city, established a record for machine made window glass last week that breaks all records for the company in the past.

- ^ a b Unlisted (Paint, Oil and Drug Review) 1907, p. 4

- ^ a b c Hamor 1913, p. 81

- ^ "Human Blowers Thing of the Past – Machines Replacing Skilled Trades and Obsolete Methods of Manufacture of Window Glass". Daily Times Gazette (Hartford City, Indiana). 1908-04-13. p. 1.

By June 1 three fourths of the window glass plants now operating by the obsolete way with human blowers will be out of blast and by July all will be idle, many never to resume by the old plan.

- ^ Fones-Wolf 2007, p. 138

- ^ Windsor 1921, p. 318

- ^ a b c Chandler 1999, pp. 115–116

- ^ Skrabec 2007, p. 124

- ^ "The Fabulous Monster: Owens Bottle Machine". Corning Museum of Glass. Retrieved 2013-02-23.

- ^ "Belle Vernon and Arnold Plant Method of Window Glass Manufacture Success Certain But Business Is Still Dull". Charleroi (PA) Mail. 1930-02-20. p. 1.

The plants at Monongahela City and Kane, and at Hartford City, Ind., which have not been rebuilt, are idle at present and probably will never be operated in the future unless business develops to a point to make their reconstruction necessary.

{{cite news}}: line feed character in|quote=at position 84 (help)

- Cited works

- Amstutz, Reverend A. Allison; Historical Committee (1943), "The First 100 Years", Centennial Brochure, First Presbyterian Church of Hartford City, Indiana

{{citation}}: Invalid|ref=harv(help) - Blackford County Gazette (advertisement) (1903). National newspaper directory and gazetteer. Containing a complete classified directory of the newspapers and periodicals published in the United States ... Boston and New York: Pettingill & Co. OCLC 40211971.

{{cite journal}}: Invalid|ref=harv(help); Missing or empty|title=(help) - Blackford County Historical Society (Ind.) (1986). A History of Blackford County, Indiana : with historical accounts of the county, 1838–1986 [and] histories of families who have lived in the county. Hartford City, Indiana: Blackford County Historical Society. OCLC 15144953.

{{cite book}}: Invalid|ref=harv(help) - Castelo, Sinuard; Clamme, Louise; Dodds, Dealie; Clamme, David; Marshall, Mary Lou; Storms, Ron (2012). Dusty Bits and Pieces. Hartford City, IN: Blackford County Historical Society. p. 127.

{{cite book}}: Invalid|ref=harv(help)CS1 maint: multiple names: authors list (link) - Chandler, Alfred Dupont (1999). Scale and scope : the dynamics of industrial capitalism. Cambridge, MA: Belknap Press. p. 765. OCLC 248361514.

{{cite book}}: Invalid|ref=harv(help) - Clamme, Louise; Castelo, Sinuard (2011). Strangers Among Us. Bloomington, IN: AuthorHouse. p. 196. OCLC 754330971.

{{cite book}}: Invalid|ref=harv(help) - Dale, George R. (1902). Directory of Hartford City, Indiana, Together with a Complete Gazetteer of Blackford County Land Owners. Troy, Ohio: George R. Dale. ISBN 978-1-153-46853-4.

{{cite book}}: Invalid|ref=harv(help) - Fleming, George Thornton; American Historical Society (1922). History of Pittsburgh and environs. New York and Chicago: The American Historical Society, Inc. p. 349. OCLC 1040253.

{{cite book}}: Invalid|ref=harv(help) - Fones-Wolf, Ken (2007). Glass Towns: Industry, Labor and Political Economy in Appalachia, 1890-1930s. Urbana, IL: University of Illinois Press. p. 236. OCLC 256490338.

{{cite book}}: Invalid|ref=harv(help) - Forstall, Richard L. (editor) (1996). Population of states and counties of the United States: 1790 to 1990 from the twenty-one decennial censuses. United States Department of Commerce, Bureau of the Census, Population Division. p. 225. ISBN 0-934213-48-8. OCLC 34927951.

{{cite book}}:|first=has generic name (help); Invalid|ref=harv(help) - Glass, James A.; Kohrman, David (2005). The Gas Boom of East Central Indiana. Image of America. Charleston, SC: Arcadia. p. 128. ISBN 978-0-7385-3963-8. OCLC 61885891.

{{cite book}}: Invalid|ref=harv(help) - Graham, Albert Adams; Perrin (editor), William Henry (1881). History of Summit County, with an outline sketch of Ohio. Chicago: Baskin & Battey. p. 1050. OCLC 8227777.

{{cite book}}:|last2=has generic name (help); Invalid|ref=harv(help) - Hamilton, Kristi; Abraham, Kent; Lankford, Susan (2005). "National Register of Historic Places Nomination: Hartford City Courthouse Square District" (Document). National Park Service.

{{cite document}}: Invalid|ref=harv(help); Unknown parameter|url=ignored (help); Unknown parameter|work=ignored (help) - Hamor, W. A. (1913). "The Present Status of the Window Glass Industry". The Journal of industrial and engineering chemistry. 5 (1). Easton, PA: American Chemical Society: 80–81. OCLC 1606890.

{{cite journal}}: Cite has empty unknown parameter:|coauthors=(help); Invalid|ref=harv(help) - Indiana Department of Inspection (1902). "Annual report of the Department of Inspection of manufacturing and mercantile establishments, laundries, bakeries, quarries, printing offices and public buildings" (1901). Indianapolis: Indiana Department of Inspection. OCLC 13018369.

{{cite journal}}: Cite journal requires|journal=(help); Invalid|ref=harv(help) - Lane, Samuel Alanson (1892). Fifty years and over of Akron and Summit County : embellished by nearly six hundred engravings--portraits of pioneer settlers, prominent citizens, business, official and professional--ancient and modern views, etc.; nine-tenth's of a century of solid local history--pioneer incidents, interesting events--industrial, commercial, financial and educational progress, biographies, etc. Akron, OH: Beacon Job Department. p. 1167. OCLC 20648565.

{{cite book}}: Cite has empty unknown parameter:|coauthors=(help); Invalid|ref=harv(help) - Merriam, William Rush; Hunt, William C.; King, William Alexander; Powers, Le Grand; North, Simon Newton Dexter; United States Census Office (1901). Census reports ... Twelfth census of the United States, taken in the year 1900. Washington: United States Census Office. OCLC 227718.

{{cite book}}: Invalid|ref=harv(help)CS1 maint: multiple names: authors list (link)

- Paquette, Jack K. (2002). Blowpipes, Northwest Ohio Glassmaking in the Gas Boom of the 1880s. Xlibris Corp. p. 559. ISBN 1-4010-4790-4. OCLC 50932436.

{{cite book}}: Cite has empty unknown parameter:|coauthors=(help); Invalid|ref=harv(help) - Skrabec, Quentin R. (2007). Michael Owens and the Glass Industry. Gretna, LA: Pelican Publishing. p. 320. OCLC 137341537.

{{cite book}}: Invalid|ref=harv(help) - United States Bureau of foreign and domestic commerce (Dept. of Commerce) (1917). The Glass Industry. Report on the cost of production of glass in the United States. Washington. p. 430. OCLC 5705310.

{{cite book}}: Invalid|ref=harv(help)CS1 maint: location missing publisher (link) - United States Congress House Committee on Ways and Means (1913). Tariff schedule, no. 3-4. Hearings before the committee on Schedule B - earths, earthenware, and glassware, January, 1913. Washington: Government Printing Office. OCLC 81218187.

{{cite book}}: Cite has empty unknown parameter:|coauthors=(help); Invalid|ref=harv(help) - Unlisted (Glass & Pottery World) (1896). "Returned". Glass & Pottery World. IV (8). Chicago: Trade Magazine Association. OCLC 1390202.

{{cite journal}}: Cite has empty unknown parameter:|coauthors=(help); Invalid|ref=harv(help) - Unlisted (Hartford City Illustrated) (1896). Hartford City illustrated : a publication devoted to the city's best interests and containing half tone engravings of prominent factories, business blocks, residences, and a selection of representative commercial and professional men and women. Daulton & Scott. p. 47. OCLC 11382905.

{{cite book}}: Invalid|ref=harv(help) - Unlisted (National Glass Budget) (1913). "Successful Start at Hartford". National Glass Budget. 29 (28). Chicago: 7. OCLC 750938784.

{{cite journal}}: Cite has empty unknown parameter:|coauthors=(help); Invalid|ref=harv(help) - Unlisted (National Glass Budget) (1917). "The Window Glass Machine". National Glass Budget. 32 (49). Chicago: 1. OCLC 750938784.

{{cite journal}}: Cite has empty unknown parameter:|coauthors=(help); Invalid|ref=harv(help) - Unlisted (Paint, Oil and Drug Review) (1899). "(untitled column on left)". Paint, Oil and Drug Review. 27 (15). Chicago: D. Van Ness Publishing Company: 13. OCLC 7711980.

{{cite journal}}: Cite has empty unknown parameter:|coauthors=(help); Invalid|ref=harv(help) - Unlisted (Paint, Oil and Drug Review) (1907). "Machine Window Glass Production". Paint, Oil and Drug Review. 44 (1). Chicago: D. Van Ness. OCLC 1585526.

{{cite journal}}: Cite has empty unknown parameter:|coauthors=(help); Invalid|ref=harv(help) - Windsor, John T. (1921). "Prosperity in Glass Manufacturing Industry". The Magazine of Wall Street. 27 (January 8, 1921). New York: Ticker Publishing Company. OCLC 7863409.

American Window Glass Made High Record Earnings in the Year Ended August Last – Largest Company of the Kind in the World

{{cite journal}}: Invalid|ref=harv(help)