Centrifugal pump

This article needs additional citations for verification. (March 2009) |

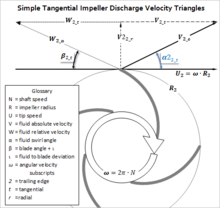

Centrifugal pumps are a sub-class of dynamic axisymmetric work-absorbing turbomachinery.[1] Centrifugal pumps are used to transport fluids by the conversion of rotational kinetic energy to the hydrodynamic energy of the fluid flow. The rotational energy typically comes from an engine or electric motor. The fluid enters the pump impeller along or near to the rotating axis and is accelerated by the impeller, flowing radially outward into a diffuser or volute chamber (casing), from where it exits.

Common uses include water, sewage, petroleum and petrochemical pumping. The reverse function of the centrifugal pump is a water turbine converting potential energy of water pressure into mechanical rotational energy.

History

According to Reti, the first machine that could be characterized as a centrifugal pump was a mud lifting machine which appeared as early as 1475 in a treatise by the Italian Renaissance engineer Francesco di Giorgio Martini.[2] True centrifugal pumps were not developed until the late 17th century, when Denis Papin built one using straight vanes. The curved vane was introduced by British inventor John Appold in 1851.

How it works

Like most pumps, a centrifugal pump converts mechanical energy from a motor to energy of a moving fluid. A portion of the energy goes into kinetic energy of the fluid motion, and some into potential energy, represented by fluid pressure (hydraulic head) or by lifting the fluid, against gravity, to a higher altitude.

The transfer of energy from the mechanical rotation of the impeller to the motion and pressure of the fluid is usually described in terms of centrifugal force, especially in older sources written before the modern concept of centrifugal force as a fictitious force in a rotating reference frame was well articulated. The concept of centrifugal force is not actually required to describe the action of the centrifugal pump.

The outlet pressure is a reflection of the pressure that applies the centripetal force that curves the path of the water to move circularly inside the pump. On the other hand, the statement that the "outward force generated within the wheel is to be understood as being produced entirely by the medium of centrifugal force" is best understood in terms of centrifugal force as a fictional force in the frame of reference of the rotating impeller; the actual forces on the water are inward, or centripetal, since that is the direction of force needed to make the water move in circles. This force is supplied by a pressure gradient that is set up by the rotation, where the pressure at the outside, at the wall of the volute, can be taken as a reactive centrifugal force. This was typical of nineteenth and early twentieth century writings, mixing the concepts of centrifugal force in informal descriptions of effects, such as those in the centrifugal pump.

Differing concepts and explanations of how centrifugal pumps work have long engendered controversy and criticism. For example, the American Expert Commission sent to the Vienna Exposition in 1873 issued a report that included observations that "they are misnamed centrifugal, because they do not operate by centrifugal force at all; they operate by pressure the same as a turbine water wheel; when people understand their method of operating we may expect much improvement." John Richards, editor of the San Francisco-based journal Industry, also downplayed the significance of centrifugal force in his essay.[3]

"This extraordinary report stands printed in a Government publication, signed by men who were, or are, eminent in mechanics, and we can only deplore the stupidity, as well as presumption of the commission who thus disposed of a subject that had twenty years before been carefully investigated by such men as Sir John Rennie, Professor Cowper, Mr. Whitelaw, Dr. James Black, Professor Rankine, and many others. The most astonishing part is, however, that this report was passed and signed by men who we can hardly suppose would fail to perceive its absurdity."

Vertical centrifugal pumps

Vertical centrifugal pumps are also referred to as cantilever pumps. They utilize a unique shaft and bearing support configuration that allows the volute to hang in the sump while the bearings are outside of the sump. This style of pump uses no stuffing box to seal the shaft but instead utilizes a "throttle bushing". A common application for this style of pump is in a parts washer.

Froth pumps

In the mineral industry, or in the extraction of oilsand, froth is generated to separate the rich minerals or bitumen from the sand and clays. Froth contains air that tends to block conventional pumps and cause loss of prime. Over history, industry has developed different ways to deal with this problem. One approach consists of using vertical pumps with a tank. Another approach is to build special pumps with an impeller capable of breaking the air bubbles. In the pulp and paper industry holes are drilled in the impeller. Air escapes to the back of the impeller and a special expeller discharges the air back to the suction tank. The impeller may also feature special small vanes between the primary vanes called split vanes or secondary vanes. Some pumps may feature a large eye, an inducer or recirculation of pressurized froth from the pump discharge back to the suction to break the bubbles.[4]

Multistage centrifugal pumps

A centrifugal pump containing two or more impellers is called a multistage centrifugal pump. The impellers may be mounted on the same shaft or on different shafts.

For higher pressures at the outlet, impellers can be connected in series. For higher flow output, impellers can be connected in parallel.

A common application of the multistage centrifugal pump is the boiler feedwater pump. For example, a 350 MW unit would require two feedpumps in parallel. Each feedpump is a multistage centrifugal pump producing 150 l/s at 21 MPa.

All energy transferred to the fluid is derived from the mechanical energy driving the impeller. This can be measured at isentropic compression, resulting in a slight temperature increase (in addition to the pressure increase).

Energy usage

The energy usage in a pumping installation is determined by the flow required, the height lifted and the length and friction characteristics of the pipeline. The power required to drive a pump (), is defined simply using SI units by:

where:

- is the input power required (W)

- is the fluid density (kg/m3)

- is the standard acceleration of gravity (9.80665 m/s2)

- is the energy Head added to the flow (m)

- is the flow rate (m3/s)

- is the efficiency of the pump plant as a decimal

The head added by the pump () is a sum of the static lift, the head loss due to friction and any losses due to valves or pipe bends all expressed in metres of fluid. Power is more commonly expressed as kilowatts (103 W, kW) or horsepower (kW = hp*0.746). The value for the pump efficiency, , may be stated for the pump itself or as a combined efficiency of the pump and motor system.

The energy usage is determined by multiplying the power requirement by the length of time the pump is operating.

Problems of centrifugal pumps

These are some difficulties faced in centrifugal pumps:[5]

- Cavitation—the net positive suction head (NPSH) of the system is too low for the selected pump

- Wear of the impeller—can be worsened by suspended solids

- Corrosion inside the pump caused by the fluid properties

- Overheating due to low flow

- Leakage along rotating shaft

- Lack of prime—centrifugal pumps must be filled (with the fluid to be pumped) in order to operate

- Surge

Centrifugal pumps for solids control

An oilfield solids control system needs many centrifugal pumps to sit on or in mud tanks. The types of centrifugal pumps used are sand pumps, submersible slurry pumps, shear pumps, and charging pumps. They are defined for their different functions, but their working principle is the same.

Magnetically coupled pumps

Magnetically coupled pumps, or magnetic drive pumps, vary from the traditional pumping style, as the motor is coupled to the pump by magnetic means rather than by a direct mechanical shaft. The pump works via a drive magnet, 'driving' the pump rotor, which is magnetically coupled to the primary shaft driven by the motor.[6] They are often used where leakage of the fluid pumped poses a great risk (e.g., aggressive fluid in the chemical or nuclear industry, or electric shock - garden fountains). They have no direct connection between the motor shaft and the impeller, so no gland is needed. There is no risk of leakage, unless the casing is broken. Since the pump shaft is not supported by bearings outside of the pump's housing, support inside the pump is provided by bushings. The materials of construction of these bushings and the required clearances of the parts may restrict the kinds of fluids for which this kind of pump may be used.

Advantages

- There are no drive seals, therefore the risk of leaks is completely eradicated. This means that hazardous liquids can be pumped without spillages.

- Less heat transfer from the motor—the pump chamber is separated from the motor by an air gap; this provides a thermal barrier.

- Complete separation of the liquid means that liquid cannot seep into the motor from the pump.

- Reduced friction.

- Magnetic coupling can be broken—if the load of the pump is too great. By the magnetic coupling 'breaking', it means the pump does not overload and get damaged.[7]

Eliminating the drive seals gets rid of leaks, friction loss, wear and noise. It provides complete separation of fluid from the pump drive, and nearly 100% transfer of motor power into pumping power.

Disadvantages

- Liquids containing ferrous particles are problematic when a magnetic drive pump is used. This is due to the particles collecting on the impeller magnet, and over time causing the pump to stop working.

- Some energy is lost in the coupling. This is primarily due to some magnetic resistance.

- If unexpectedly heavy loads occur it may cause the coupling to slip.

Principle of operation

The impeller of such a pump is magnetically coupled with the motor, across a separation wall which is resistant to the fluid pumped. The motor drives a rotor carrying one or several pairs of permanent magnets, and these drag around a second pair(s) of permanent magnets attached to the pump impeller.

Priming

Most centrifugal pumps are not self-priming. In other words, the pump casing must be filled with liquid before the pump is started, or the pump will not be able to function. If the pump casing becomes filled with vapors or gases, the pump impeller becomes gas-bound and incapable of pumping. To ensure that a centrifugal pump remains primed and does not become gas-bound, most centrifugal pumps are located below the level of the source from which the pump is to take its suction. The same effect can be gained by supplying liquid to the pump suction under pressure supplied by another pump placed in the suction line.

See also

- Axial flow pump

- Turbopump

- Pump

- Turbine

- Net positive suction head (NPSH)

- Specific speed (Ns or Nss)

- Thermodynamic pump testing

- Effects of mach number and shock losses in turbomachines

References

- ^ Shepard, Dennis G. (1956). Principles of Turbomachinery. McMillan. ISBN 0-471-85546-4. LCCN 56002849.

- ^ Reti, Ladislao; Di Giorgio Martini, Francesco (Summer 1963). "Francesco di Giorgio (Armani) Martini's Treatise on Engineering and Its Plagiarists". Technology and Culture. 4 (3): 287–298 (290). doi:10.2307/3100858.

- ^ Richards, John (1894). Centrifugal pumps: an essay on their construction and operation, and some account of the origin and development in this and other countries. The Industrial Publishing Company. pp. 40–41.

- ^ Baha Abulnaga (2004). Pumping Oilsand Froth (PDF). 21st International Pump Users Symposium, Baltimore, Maryland. Published by Texas A&M University, Texas, USA.

- ^ Larry Bachus, Angle Custodio (2003). Know and understand centrifugal pumps. Elsevier Ltd. ISBN 1856174093.

- ^ Pump Handbook:third edition

- ^ Pumping Profits & Productivity, The Magic Of Magnetic Drive Pumps: Part I