Gas–liquid contactor

A gas-liquid contactor is a particular chemical equipment used to realize the mass and heat transfer between a gas phase and a liquid phase. Gas-liquid contactors can be used in separation processes (e.g. distillation, absorption) or as gas-liquid reactors or to achieve both purposes within the same device (e.g. reactive distillation).

Typologies

They are divided into two main categories:[1]

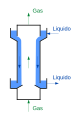

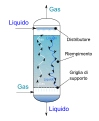

- differential gas-liquid contactors: the mass transfer happens within the entire length of the contactor[1] and the vapor–liquid equilibrium is not reached in any point of the equipment;[1]

- stagewise gas-liquid contactors: the vapor–liquid equilibrium is reached within each stage of the equipment and mass transfer happens in a part only of the volume of each stage.

Examples of differential gas-liquid contactors are:

Examples of stagewise gas-liquid contactors are:

Pro and cons

Some important factors to take into account to choice the typology of gas-liquid contactor more suitable for a particular application are:

- liquid hold-up

- surface area of the gas-liquid interface.

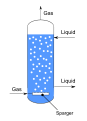

In particular heat and mass transfer velocity is higher for equipment with higher values of gas-liquid interface surface area, so gas-liquid contactors with high surface area (e.g. packed column, spray tower) are often preferred when it is important to lower the cost of the equipment.

Liquid hold-up is also an important factor for the economy of the process, because for low values of liquid hold-up a bigger equipment is needed to have the same heat and mass transfer velocity. For this reason, gas-liquid contactors with low liquid-hold-up (e.g. falling-film column) in general are not used at industrial scale.

Notes

- ^ a b c (Ghosal 2011, pp. 253–257)

Bibliography

- Robert Perry, Don W. Green, Perry's Chemical Engineers' Handbook, 8th ed., McGraw-Hill, 2007. ISBN 0071422943

- Ghosal, Salil K.; Datta, Siddhartha (2011). Introduction to Chemical Engineering. Tata McGraw-Hill Education. ISBN 0074601407.