Dust explosion

This article needs additional citations for verification. (June 2015) |

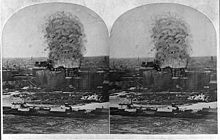

A dust explosion is the rapid combustion of fine particles suspended in the air, often but not always in an enclosed location. Dust explosions can occur where any dispersed powdered combustible material is present in high enough concentrations in the atmosphere or other oxidizing gaseous medium such as oxygen.

Dust explosions are a frequent hazard in underground coal mines, in grain elevators, and other industrial environments. On the other hand, they are also commonly used by special effects artists, filmmakers, and pyrotechnicians, given their spectacular appearance and ability to be safely contained under certain carefully controlled conditions.

Terminology

If rapid combustion occurs in a confined space, enormous overpressures can build up, causing major structural damage and flying shrapnel. The sudden release of energy from a "detonation" can produce a shockwave, either in open air or in a confined space. If the spread of flame is at subsonic speed, the phenomenon is sometimes called a "deflagration", although looser usage calls both phenomena "explosions".

Dust explosions may be classified as being either "primary" or "secondary" in nature. Primary dust explosions may occur inside process equipment or similar enclosures, and are generally controlled by pressure relief through purpose-built ducting to the external atmosphere. Secondary dust explosions are the result of dust accumulation inside a building being disturbed and ignited by the primary explosion, resulting in a much more dangerous uncontrolled explosion inside the workplace. Historically, fatalities from dust explosions have largely been the result of secondary dust explosions.[citation needed]

Conditions required

There are four necessary conditions for a dust explosion:[1]

- A combustible dust

- The dust is suspended in the air at a sufficiently high concentration

- There is an oxidant (typically atmospheric oxygen)

- There is an ignition source

In some traditional analyses of dust explosions, confinement is considered to be a fifth requirement; this is not an essential condition, but can greatly aggravate the physical damage that results.

Sources of dust

Many common materials which are known to burn can generate a dust explosion, such as coal and sawdust. In addition, many otherwise mundane organic materials can also be dispersed into a dangerous dust cloud, such as grain, flour, starch, sugar, powdered milk, cocoa, coffee, and pollen. Powdered metals (such as aluminum, magnesium, and titanium) can form explosive suspensions in air, if finely divided.

Explosive dust can arise from activities such as transporting grain, and grain silos have often been demolished violently. Mining of coal leads to coal dust, and flour mills likewise have large amounts of flour dust as a result of milling. A gigantic explosion of flour dust destroyed a mill in Minnesota on May 2, 1878, killing 14 workers at the Washburn A Mill and another four in adjacent buildings.[2] A similar problem occurs in sawmills and other places dedicated to woodworking.

Although not strictly a dust, paper particles emitted during processing - especially rolling, unrolling, calendaring/slitting, and sheet-cutting - are also known to pose an explosion hazard. Enclosed paper mill areas subject to such dangers commonly maintain very high air humidities to reduce the chance of airborne paper dust explosions.

In special effects pyrotechnics, lycopodium powder[citation needed] and non-dairy creamer[3] are two common means of producing safe, controlled fire effects. Thermobaric weapons, depending upon their fuel, are also a potential and intentional source of dust.

To support rapid combustion, the dust must consist of very small particles with a high surface area to volume ratio, thereby making the collective or combined surface area of all the particles very large in comparison to a dust of larger particles. Dust is defined as powders with particles less than about 500 micrometres in diameter, but finer dust will present a much greater hazard than coarse particles by virtue of the larger total surface area of all the particles.

Concentration

Below a certain value, the lower explosive limit (LEL),[4] there is simply insufficient dust to support the combustion at the rate required for an explosion. A combustible concentration at or below 25% of the LEL is considered safe.[5] Similarly, if the fuel/air ratio increases above the upper explosive limit (UEL), there is insufficient oxidant to permit combustion to continue at the necessary rate.

Oxidant

Typically, normal atmospheric oxygen can be sufficient to support a dust explosion if the other necessary conditions are also present. High-oxygen or pure oxygen environments are considered to be especially hazardous, as are strong oxidizing gases such as chlorine and fluorine. Also, particulate suspensions of compounds with a high oxidative potential, such as peroxides, chlorates, nitrates, perchlorates, and dichromates, can increase risk of an explosion if combustible materials are also present.

Sources of ignition

There are many sources of ignition, and a naked flame need not be the only one: over one half of the dust explosions in Germany in 2005 were from non-flame sources.[4] Common sources of ignition include:

- electrostatic discharge (e.g. an improperly installed conveyor belt, which can act like a Van de Graaff generator)

- friction

- electrical arcing from machinery or other equipment

- hot surfaces (e.g. overheated bearings)

- fire

However, it is often difficult to determine the exact source of ignition when investigating after an explosion. When a source cannot be found, ignition will often be attributed to static electricity. Static charges can be generated by external sources, or can be internally generated by friction at the surfaces of particles themselves as they collide or move past one another.

Mechanism

Dusts have a very large surface area compared to their mass. Since burning can only occur at the surface of a solid or liquid, where it can react with oxygen, this causes dusts to be much more flammable than bulk materials. For example, a 1 kilogram (2.2 lb) sphere of a combustible material with a density of 1 g/cm3 would be about 12.4 centimetres (4.9 in) in diameter, and have a surface area of 0.048 square metres (0.52 sq ft). However, if it were broken up into spherical dust particles 50 µm in diameter (about the size of flour particles) it would have a surface area of 120 square metres (1,300 sq ft). This greatly-increased surface area allows the material to burn much faster, and the extremely small mass of each particle allows them to catch on fire with much less energy than the bulk material, as there is no heat loss to conduction within the material.

When this mixture of fuel and air is ignited, especially in a confined space such as a warehouse or silo, a significant increase in pressure is created, often more than sufficient to demolish the structure. Even materials that are traditionally thought of as nonflammable (such as aluminum), or slow burning (such as wood), can produce a powerful explosion when finely divided, and can be ignited by even a small spark.

- Demonstration of an open-air dust explosion

-

Experimental setup

-

Finely-ground flour is dispersed

-

Cloud of flour is ignited

-

Fireball spreads rapidly

-

Intense radiant heat has nothing to ignite here

-

Fireball and superheated gases rise

-

Aftermath of explosion, with unburned flour on the ground

Effects

A dust explosion can cause major damage to structures, equipment, and personnel from violent overpressure or shockwave effects. Flying objects and debris can cause further damage. Intense radiant heat from a fireball can ignite the surroundings, or cause severe skin burns in unprotected persons. In a tightly enclosed space, the sudden depletion of oxygen can cause asphyxiation.

Protection and mitigation

Much research has been carried out in Europe and elsewhere to understand how to control these dangers, but dust explosions still occur. The alternatives for making processes and plants safer depend on the industry.

In the coal mining industry, a methane explosion can initiate a coal dust explosion, which can then engulf an entire mine pit. As a precaution, incombustible stone dust may be spread along mine roadways, or stored in trays hanging from the roof, to dilute the coal dust stirred up by a shockwave to the point where it cannot burn. Mines may also be sprayed with water to inhibit ignition.

Some industries exclude oxygen from dust-raising processes, a precaution known as "inerting". Typically this uses nitrogen, carbon dioxide, or argon, which are incombustible gases which can displace oxygen. The same method is also used in large storage tanks where flammable vapors can accumulate. However, use of oxygen-free gases brings a risk of asphyxiation of the workers. Workers who need illumination in enclosed spaces where a dust explosion is a high risk often use lamps designed for underwater divers, as they have no risk of producing an open spark due to their sealed waterproof design.

Good housekeeping practices, such as eliminating build-up of combustible dust deposits that could be disturbed and lead to a secondary explosion, also help mitigate the problem.

Best engineering control measures which can be found in the National Fire Protection Association (NFPA) Combustible Dust Standards[6] include:

- Wetting

- Oxidant concentration reduction

- Deflagration venting

- Deflagration pressure containment

- Deflagration suppression

- Deflagration venting through a dust retention and flame-arresting device

Notable incidents

Dust clouds are a common source of explosions, causing an estimated 2,000 explosions annually in Europe.[7] The table lists notable incidents worldwide.

| Event | Date | Location | Country | Source material | Fatalities | Injuries | Notes |

|---|---|---|---|---|---|---|---|

| Washburn "A" Mill explosion | May 2, 1878 | Minneapolis, Minnesota | grain dust | 22 | Destroyed the largest grain mill in the world and leveled five other mills, effectively reducing the milling capacity of Minneapolis by one-third to one-half. Prompted mills throughout the country to install better ventilation systems to prevent dust build-up. | ||

| Mount Mulligan mine disaster | September 19, 1921 | Mount Mulligan, Queensland | coal dust | 75 | The series of coal dust explosions within a mine rocked the close-knit township and was audible as far as 30 kilometres (19 mi) away. | ||

| Benxihu Colliery explosion | April 26, 1942 | Benxi, Liaoning | coal dust and gas | 1,549 | 34% of the miners working that day were killed. This is the world's worst-ever coal-mining accident. | ||

| Westwego grain elevator explosion | December 22, 1977 | Westwego, Louisiana | grain dust | 36 | 13 | [8] | |

| Galveston grain elevator explosion | December 27, 1977 | Galveston, Texas | grain dust | 20 | [8] | ||

| Bird's Custard factory explosion | November 18, 1981 | Banbury | corn starch | 9 | [7][9] | ||

| Harbin textile factory explosion | March 17, 1987 | Harbin | flax dust | 58 | 177 | [10] | |

| Blaye grain explosion | August 1997 | Blaye | grain dust | 11 | 1 | Explosion in a grain storage facility at the Société d’Exploitation Maritime Blayaise killed 11 people in nearby offices and injured one.[7] | |

| West Pharmaceutical Services explosion | January 29, 2003 | Kinston, North Carolina | polyethylene dust | 6 | 38 | ||

| Imperial Sugar explosion | February 7, 2008 | Port Wentworth, Georgia | sugar dust | 14 | 42 | [7] | |

| 2014 Kunshan explosion | August 2, 2014 | Kunshan | metal powder | 146 | 114 | ||

| Formosa Fun Coast explosion | June 27, 2015 | New Taipei | colored starch powder | 14 | 498 | Explosion when Holi-like colored powder was released at an outdoor music and color festival at the Formosa Fun Coast. | |

| Bosley Wood flour mill explosion | July 17, 2015 | Bosley, Cheshire | wood flour | 4 | 4 | [11][12] |

See also

References

- ^ [1] Archived 2005-09-21 at the Wayback Machine

- ^ http://www.mnopedia.org/event/1878-washburn-mill-explosion

- ^ "Detonation Films - Why Coffee Creamer?". Retrieved March 20, 2011.

- ^ a b !StaubEx_0805_e.pdf

- ^ NFPA 69 8.3.1

- ^ http://www.nfpa.org/codes-and-standards/all-codes-and-standards/list-of-codes-and-standards

- ^ a b c d Hought, Julian (28 February 2011). "Dust to Dust". Retrieved 2015-07-02.

- ^ a b "Explosion suits settled". The Day. New London, Connecticut. 24 April 1980. p. 26.

- ^ "Corn Starch Dust Explosion at General Foods Ltd, Banbury, Oxfordshire – 18th November 1981". Great Britain: January 1983. Occupational Health & Safety Information Service, UK. ISBN 0-11-883673-0

- ^ "47 Die, 179 Injured in Blast at Linen Mill in Northeast China". Los Angeles Times. March 17, 1987. Retrieved 2015-07-02.

- ^ "Bosley explosion: Four missing in Wood Flour Mills blast". July 17, 2015. Retrieved 2015-12-02.

- ^ "Bosley Wood flour mill explosion: Fourth body found in wreckage of building gutted by blast". July 27, 2015. Retrieved 2015-12-02.

- John Barton (ed.): Dust Explosion Prevention and Protection (A Practical Guide) Institution of Chemical Engineers, Rugby 2002, ISBN 0-85295-410-7.

- Rolf K. Eckhoff: Dust Explosions in the Process Industries, 2nd ed. Butterworth-Heinemann, Oxford 1997, ISBN 0-7506-3270-4.

External links

Incidents in France and the US:

- Combustible dust explosion investigation products from the Chemical Safety Board

- Combustible Dust Policy Institute-ATEX

- OSHA case studies of dust explosions

Protecting process plant and grain handling facilities from the risk of dust hazard explosions: