Internal combustion engine: Difference between revisions

m →Reciprocating engines: Fixed link. |

Rearranged sections, removed space before dot. Done using GNU Emacs. |

||

| Line 57: | Line 57: | ||

The pistons are short cylindrical parts which seal one end of the cylinder from the high pressure of the compressed air and combustion products and slide continuously withing it while the engine is in operation. Each piston has [[piston ring|rings]] fitted around its circumference that mostly prevent the gases from leaking into the crankcase or the oil into the combustion chamber. A [[crankcase ventilation system|ventilation system]] drives small amount of gas that escape past the pistons as a part of normal operation (the blow-by gases) out of the crankcase so that it doesn't accumulate contaminating the oil and creating corrosion. In two stroke gasoline engines the crankcase is part of the air–fuel path and due to the continuous flow of it they don't need a separate crankcase ventilation system. |

The pistons are short cylindrical parts which seal one end of the cylinder from the high pressure of the compressed air and combustion products and slide continuously withing it while the engine is in operation. Each piston has [[piston ring|rings]] fitted around its circumference that mostly prevent the gases from leaking into the crankcase or the oil into the combustion chamber. A [[crankcase ventilation system|ventilation system]] drives small amount of gas that escape past the pistons as a part of normal operation (the blow-by gases) out of the crankcase so that it doesn't accumulate contaminating the oil and creating corrosion. In two stroke gasoline engines the crankcase is part of the air–fuel path and due to the continuous flow of it they don't need a separate crankcase ventilation system. |

||

The [[cylinder head]] is attached to the engine block by numerous [[bolt]]s. It has several functions. The cylinder head seals the cylinders on the side opposite to the pistons; it contains short ducts (the ''ports'') for intake and exhaust and the associated intake [[poppet valves|valves]] that open to let the cylinder be filled with fresh air and exhaust valves that open to allow the combustion gases to escape. The cylinder head also holds the [[spark plug]] in the case of spark ignition engines and the [[injector]] for engines that use direct injection. All CI use direct injection. SI engines can use a [[carburetor]], port injection or [[gasoline direct injection|direct injection]] |

The [[cylinder head]] is attached to the engine block by numerous [[bolt]]s. It has several functions. The cylinder head seals the cylinders on the side opposite to the pistons; it contains short ducts (the ''ports'') for intake and exhaust and the associated intake [[poppet valves|valves]] that open to let the cylinder be filled with fresh air and exhaust valves that open to allow the combustion gases to escape. The cylinder head also holds the [[spark plug]] in the case of spark ignition engines and the [[injector]] for engines that use direct injection. All CI use direct injection. SI engines can use a [[carburetor]], port injection or [[gasoline direct injection|direct injection]]. Most SI engines have a single spark plug per cylinder but [[dual ignition|some have 2]]. A [[head gasket]] prevents the gas from leaking between the cylinder head and the engine block. The opening and closing of the valves is controlled by one or several [[camshaft]]s and springs –or in some engines– a [[desmodromic valve|desmodromic mechanism]] that uses no springs. The camshaft may press directly the stem of the valve or may act upon a [[rocker arm]], again, either directly or through a [[pushrod]]. |

||

[[File:18XER engine block.jpg|thumb|Engine block seen from below. The cylinders, oil spay nozzle and half of the main bearings are clearly visible.]] |

[[File:18XER engine block.jpg|thumb|Engine block seen from below. The cylinders, oil spay nozzle and half of the main bearings are clearly visible.]] |

||

| Line 82: | Line 82: | ||

Many engines overlap these steps in time; turbine engines do all steps simultaneously at different parts of the engines. |

Many engines overlap these steps in time; turbine engines do all steps simultaneously at different parts of the engines. |

||

=== |

=== Ignition === |

||

| ⚫ | All '''internal combustion engines''' depend on [[combustion]] of a [[Fuel#Chemical|chemical fuel]], typically with oxygen from the air (though it is possible to inject [[nitrous oxide]] to do more of the same thing and gain a power boost). The combustion process typically results in the production of a great quantity of heat, as well as the production of steam and carbon dioxide and other chemicals at very high temperature; the temperature reached is determined by the chemical make up of the fuel and oxidisers (see [[stoichiometry]]), as well as by the compression and other factors. |

||

| ⚫ | The most common modern fuels are made up of [[hydrocarbon]]s and are derived mostly from [[fossil fuel]]s ([[petroleum]]). Fossil fuels include [[diesel fuel]], [[gasoline]] and [[liquefied petroleum gas|petroleum gas]], and the rarer use of [[propane]]. Except for the fuel delivery components, most internal combustion engines that are designed for gasoline use can run on [[natural gas]] or liquefied petroleum gases without major modifications. Large diesels can run with air mixed with gases and a pilot diesel fuel ignition injection. Liquid and gaseous [[biofuel]]s, such as [[ethanol fuel|ethanol]] and [[biodiesel]] (a form of diesel fuel that is produced from crops that yield [[triglyceride]]s such as [[soybean]] oil), can also be used. Engines with appropriate modifications can also run on [[hydrogen]] gas, [[wood gas]], or [[wood gas|charcoal gas]], as well as from so-called [[wood gas|producer gas]] made from other convenient biomass. Experiments have also been conducted using powdered solid fuels, such as the [[magnesium injection cycle]]. |

||

Internal combustion engines require ignition of the mixture, either by [[spark plug|spark ignition (SI)]] or [[diesel engine|compression ignition]] (CI). Before the invention of reliable electrical methods, hot tube and flame methods were used. Experimental engines with [[laser ignition]] have been built.<ref>{{cite news |url=http://www.physorg.com/news/2011-04-laser-revolution-internal-combustion.html |title=Laser sparks revolution in internal combustion engines |work=Physorg.com |date=2011-04-20 |accessdate=2013-12-26}}</ref> |

Internal combustion engines require ignition of the mixture, either by [[spark plug|spark ignition (SI)]] or [[diesel engine|compression ignition]] (CI). Before the invention of reliable electrical methods, hot tube and flame methods were used. Experimental engines with [[laser ignition]] have been built.<ref>{{cite news |url=http://www.physorg.com/news/2011-04-laser-revolution-internal-combustion.html |title=Laser sparks revolution in internal combustion engines |work=Physorg.com |date=2011-04-20 |accessdate=2013-12-26}}</ref> |

||

==== Gasoline Ignition Process ==== |

|||

Gasoline engine ignition systems generally rely on a combination of [[alternator (auto)|alternator]] or [[Electrical generator|generator]] and [[lead–acid battery]] for electrical power. The battery supplies electrical power for cranking, and supplies electrical power when the engine is off. The battery also supplies electrical power during rare run conditions where the alternator cannot maintain more than 13.8 volts (for a common 12V automotive electrical system). As alternator voltage falls below 13.8 volts, the lead-acid storage battery increasingly picks up electrical load. During virtually all running conditions, including normal idle conditions, the alternator supplies primary electrical power. |

Gasoline engine ignition systems generally rely on a combination of [[alternator (auto)|alternator]] or [[Electrical generator|generator]] and [[lead–acid battery]] for electrical power. The battery supplies electrical power for cranking, and supplies electrical power when the engine is off. The battery also supplies electrical power during rare run conditions where the alternator cannot maintain more than 13.8 volts (for a common 12V automotive electrical system). As alternator voltage falls below 13.8 volts, the lead-acid storage battery increasingly picks up electrical load. During virtually all running conditions, including normal idle conditions, the alternator supplies primary electrical power. |

||

| Line 101: | Line 97: | ||

While gasoline internal combustion engines are much easier to start in cold weather than diesel engines, they can still have cold weather starting problems under extreme conditions. For years the solution was to park the car in heated areas. In some parts of the world the oil was actually drained and heated over night and returned to the engine for cold starts. In the early 1950s the '''gasoline Gasifier''' unit was developed, where, on cold weather starts, raw gasoline was diverted to the unit where part of the fuel was burned causing the other part to become a hot vapor sent directly to the intake valve manifold. This unit was quite popular until electric engine block heaters became standard on gasoline engines sold in cold climates.<ref>{{cite journal |url=http://books.google.com.au/books?id=zdwDAAAAMBAJ&pg=PA149 |title=Gasifier Aids Motor Starting Under Arctic Conditions |journal=Popular Mechanics |date=January 1953 |page=149 }}</ref> |

While gasoline internal combustion engines are much easier to start in cold weather than diesel engines, they can still have cold weather starting problems under extreme conditions. For years the solution was to park the car in heated areas. In some parts of the world the oil was actually drained and heated over night and returned to the engine for cold starts. In the early 1950s the '''gasoline Gasifier''' unit was developed, where, on cold weather starts, raw gasoline was diverted to the unit where part of the fuel was burned causing the other part to become a hot vapor sent directly to the intake valve manifold. This unit was quite popular until electric engine block heaters became standard on gasoline engines sold in cold climates.<ref>{{cite journal |url=http://books.google.com.au/books?id=zdwDAAAAMBAJ&pg=PA149 |title=Gasifier Aids Motor Starting Under Arctic Conditions |journal=Popular Mechanics |date=January 1953 |page=149 }}</ref> |

||

==== Diesel Ignition Process ==== |

|||

[[Diesel engine]]s and [[HCCI]] (Homogeneous charge compression ignition) engines, rely solely on heat and pressure created by the engine in its compression process for ignition. The compression level that occurs is usually twice or more than a gasoline engine. Diesel engines take in air only, and shortly before peak compression, spray a small quantity of diesel fuel into the cylinder via a fuel injector that allows the fuel to instantly ignite. HCCI type engines take in both air and fuel, but continue to rely on an unaided auto-combustion process, due to higher pressures and heat. This is also why diesel and HCCI engines are more susceptible to cold-starting issues, although they run just as well in cold weather once started. Light duty diesel engines with [[indirect injection]] in automobiles and light trucks employ [[glowplug]]s that pre-heat the [[combustion chamber]] just before starting to reduce no-start conditions in cold weather. Most diesels also have a battery and charging system; nevertheless, this system is secondary and is added by manufacturers as a luxury for the ease of starting, turning fuel on and off (which can also be done via a switch or mechanical apparatus), and for running auxiliary electrical components and accessories. Most new engines rely on electrical and electronic [[engine control unit]]s (ECU) that also adjust the combustion process to increase efficiency and reduce emissions. |

[[Diesel engine]]s and [[HCCI]] (Homogeneous charge compression ignition) engines, rely solely on heat and pressure created by the engine in its compression process for ignition. The compression level that occurs is usually twice or more than a gasoline engine. Diesel engines take in air only, and shortly before peak compression, spray a small quantity of diesel fuel into the cylinder via a fuel injector that allows the fuel to instantly ignite. HCCI type engines take in both air and fuel, but continue to rely on an unaided auto-combustion process, due to higher pressures and heat. This is also why diesel and HCCI engines are more susceptible to cold-starting issues, although they run just as well in cold weather once started. Light duty diesel engines with [[indirect injection]] in automobiles and light trucks employ [[glowplug]]s that pre-heat the [[combustion chamber]] just before starting to reduce no-start conditions in cold weather. Most diesels also have a battery and charging system; nevertheless, this system is secondary and is added by manufacturers as a luxury for the ease of starting, turning fuel on and off (which can also be done via a switch or mechanical apparatus), and for running auxiliary electrical components and accessories. Most new engines rely on electrical and electronic [[engine control unit]]s (ECU) that also adjust the combustion process to increase efficiency and reduce emissions. |

||

| Line 246: | Line 242: | ||

== Fuels and oxidizers == |

== Fuels and oxidizers == |

||

| ⚫ | All '''internal combustion engines''' depend on [[combustion]] of a [[Fuel#Chemical|chemical fuel]], typically with oxygen from the air (though it is possible to inject [[nitrous oxide]] to do more of the same thing and gain a power boost). The combustion process typically results in the production of a great quantity of heat, as well as the production of steam and carbon dioxide and other chemicals at very high temperature; the temperature reached is determined by the chemical make up of the fuel and oxidisers (see [[stoichiometry]]), as well as by the compression and other factors. |

||

Engines are often classified by the fuel (or [[propellant]]) they used. |

|||

=== Fuels === |

=== Fuels === |

||

| ⚫ | The most common modern fuels are made up of [[hydrocarbon]]s and are derived mostly from [[fossil fuel]]s ([[petroleum]]). Fossil fuels include [[diesel fuel]], [[gasoline]] and [[liquefied petroleum gas|petroleum gas]], and the rarer use of [[propane]]. Except for the fuel delivery components, most internal combustion engines that are designed for gasoline use can run on [[natural gas]] or liquefied petroleum gases without major modifications. Large diesels can run with air mixed with gases and a pilot diesel fuel ignition injection. Liquid and gaseous [[biofuel]]s, such as [[ethanol fuel|ethanol]] and [[biodiesel]] (a form of diesel fuel that is produced from crops that yield [[triglyceride]]s such as [[soybean]] oil), can also be used. Engines with appropriate modifications can also run on [[hydrogen]] gas, [[wood gas]], or [[wood gas|charcoal gas]], as well as from so-called [[wood gas|producer gas]] made from other convenient biomass. Experiments have also been conducted using powdered solid fuels, such as the [[magnesium injection cycle]]. |

||

Presently, fuels used include: |

Presently, fuels used include: |

||

*[[Petroleum]]: |

*[[Petroleum]]: |

||

**Petroleum spirit ([[North American English|North American]] term: [[gasoline]], [[British English|British]] term: petrol) |

**Petroleum spirit ([[North American English|North American]] term: [[gasoline]], [[British English|British]] term: petrol) |

||

| Line 276: | Line 275: | ||

[[Diesel engine]]s are generally heavier, noisier, and more powerful at lower speeds than [[gasoline engine]]s. They are also more fuel-efficient in most circumstances and are used in heavy road vehicles, some automobiles (increasingly so for their increased [[fuel efficiency]] over gasoline engines), ships, [[railway]] [[locomotive]]s, and light [[aircraft]]. Gasoline engines are used in most other road vehicles including most cars, [[motorcycle]]s, and [[moped]]s. Note that in [[Europe]], sophisticated diesel-engined cars have taken over about 45% of the market since the 1990s. There are also engines that run on [[hydrogen car|hydrogen]], [[methanol]], [[ethanol]], [[liquefied petroleum gas]] (LPG), [[biodiesel]], [[wood|paraffin]] and [[tractor vaporizing oil]] (TVO). |

[[Diesel engine]]s are generally heavier, noisier, and more powerful at lower speeds than [[gasoline engine]]s. They are also more fuel-efficient in most circumstances and are used in heavy road vehicles, some automobiles (increasingly so for their increased [[fuel efficiency]] over gasoline engines), ships, [[railway]] [[locomotive]]s, and light [[aircraft]]. Gasoline engines are used in most other road vehicles including most cars, [[motorcycle]]s, and [[moped]]s. Note that in [[Europe]], sophisticated diesel-engined cars have taken over about 45% of the market since the 1990s. There are also engines that run on [[hydrogen car|hydrogen]], [[methanol]], [[ethanol]], [[liquefied petroleum gas]] (LPG), [[biodiesel]], [[wood|paraffin]] and [[tractor vaporizing oil]] (TVO). |

||

=== Hydrogen === |

==== Hydrogen ==== |

||

{{Main|Hydrogen internal combustion engine vehicle}} |

{{Main|Hydrogen internal combustion engine vehicle}} |

||

| Line 418: | Line 417: | ||

*[http://web.mit.edu/professional/short-programs/courses/internal_combustion_engines.html MIT Overview] - Present & Future Internal Combustion Engines: Performance, Efficiency, Emissions, and Fuels |

*[http://web.mit.edu/professional/short-programs/courses/internal_combustion_engines.html MIT Overview] - Present & Future Internal Combustion Engines: Performance, Efficiency, Emissions, and Fuels |

||

*[http://www.sandia.gov/ecn Engine Combustion Network] - Open forum for international collaboration among experimental and computational researchers in engine combustion. |

*[http://www.sandia.gov/ecn Engine Combustion Network] - Open forum for international collaboration among experimental and computational researchers in engine combustion. |

||

*[http://www.technologyreview.com/energy/27124/page1/?a=f Automakers Show Interest in |

*[http://www.technologyreview.com/energy/27124/page1/?a=f Automakers Show Interest in ffan Unusual Engine Design] |

||

* [http://www.howstuffworks.com/engine1.htm How Car Engines Work] |

* [http://www.howstuffworks.com/engine1.htm How Car Engines Work] |

||

*A file on unusual engines [http://www.douglas-self.com/MUSEUM/POWER/unusualICeng/unusualICeng.htm] |

*A file on unusual engines [http://www.douglas-self.com/MUSEUM/POWER/unusualICeng/unusualICeng.htm] |

||

Revision as of 03:02, 12 October 2014

C – crankshaft.

E – exhaust camshaft.

I – inlet camshaft.

P – piston.

R – connecting rod.

S – spark plug.

V – valves. red: exhaust, blue: intake.

W – cooling water jacket.

gray structure – engine block.

An internal combustion engine (ICE) is an engine where the combustion of a fuel occurs with an oxidizer (usually air) in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal combustion engine the expansion of the high-temperature and high-pressure gases produced by combustion apply direct force to some component of the engine. The force is applied typically to pistons, turbine blades, or a nozzle. This force moves the component over a distance, transforming chemical energy into useful mechanical energy. The first commercially successful internal combustion engine was created by Étienne Lenoir around 1859.[1]

Typically an ICE is fed with fossil fuels like natural gas or petroleum products such as gasoline, diesel fuel or fuel oil. There's a growing usage of renewable fuels like biodiesel for compression ignition engines and bioethanol for spark ignition engines. Hydrogen can be used as a fuel, where it would act as an energy carrier rather than as a primary energy source because it's not found unbounded in nature in appreciable quantities. It's possible to generate pure hydrogen from renewable energy. See hydrogen economy.

The term internal combustion engine usually refers to an engine in which combustion is intermittent, such as the more familiar four-stroke and two-stroke piston engines, along with variants, such as the six-stroke piston engine and the Wankel rotary engine. A second class of internal combustion engines use continuous combustion: gas turbines, jet engines and most rocket engines, each of which are internal combustion engines on the same principle as previously described.[1][2] Firearms are are also a form of internal combustion engine.[2]

Internal combustion engines are quite different from external combustion engines, such as steam or Stirling engines, in which the energy is delivered to a working fluid not consisting of, mixed with, or contaminated by combustion products. Working fluids can be air, hot water, pressurized water or even liquid sodium, heated in a boiler. ICEs are usually powered by energy-dense fuels such as gasoline or diesel, liquids derived from fossil fuels. While there are many stationary applications, most ICEs are used in mobile applications and are the dominant power supply for cars, aircraft, and boats.

History

Nomenclature

At one time, the word engine (from Latin, via Old French, ingenium, "ability") meant any piece of machinery — a sense that persists in expressions such as siege engine. A "motor" (from Latin motor, "mover") is any machine that produces mechanical power. Traditionally, electric motors are not referred to as "Engines"; however, combustion engines are often referred to as "motors." (An electric engine refers to a locomotive operated by electricity.)

Applications

Reciprocating piston engines are by far the most common power source for land vehicles including automobiles, motorcycles, locomotives and ships. Wankel engines are found on some automobiles and motorcycles.

Where very high power-to-weight ratios are required, internal combustion engines appear in the form of combustion turbines. Powered aircraft typically use an ICE which may be a reciprocating engine. Airplanes can also use jet engines and helicopters can also employ turboshafts; both of these are types of turbines. In addition to providing propulsion, airliners employ a separate ICE as an auxiliary power unit.

ICEs also have a role in large scale electric power generation where they're found in the form of combustion turbines in combined cycle power plants with typical electrical output in the range of 100 MW to 1 GW. The high temperature exhaust is used to boil and superheat water to run a steam turbine. Thus, more energy is extracted from the fuel that could be extracted by the combustion turbine alone. In combined cycle power plants efficiencies in the range of 50 % to 60 % are typical. In a smaller scale Diesel generators are used for backup power and for providing electrical power to areas not connected to an electric grid.

Two stroke gasoline small engines are a common power source for chainsaws, leafblowers and lawnmowers.

Engine configurations

Internal combustion engines can be classified by their configuration.

Common layouts of engines are:

- Two-stroke engine

- Four-stroke engine (Otto cycle)

- Six-stroke engine

- Diesel engine

- Atkinson cycle

- Miller cycle

Continuous combustion:

- Gas turbine

- Jet engine (including turbojet, turbofan, ramjet, rocket, etc.)

Reciprocating engines

Structure

The base of a reciprocating internal combustion engine is the engine block which is typically made of cast iron or aluminium. The engine block contains the cylinders. Water cooled engines contain passages in the engine block where cooling fluid circulate (the water jacket). Some small engines are air cooled, and instead of having a water jacket the cylinder block has fins protruding away from it to cool by directly transferring heat to the air. The cylinder walls are usually finished by honing to obtain a cross hatch which is better able to retain the oil. A too rough surface would quickly harm the engine by excessive wear on the piston.

The pistons are short cylindrical parts which seal one end of the cylinder from the high pressure of the compressed air and combustion products and slide continuously withing it while the engine is in operation. Each piston has rings fitted around its circumference that mostly prevent the gases from leaking into the crankcase or the oil into the combustion chamber. A ventilation system drives small amount of gas that escape past the pistons as a part of normal operation (the blow-by gases) out of the crankcase so that it doesn't accumulate contaminating the oil and creating corrosion. In two stroke gasoline engines the crankcase is part of the air–fuel path and due to the continuous flow of it they don't need a separate crankcase ventilation system.

The cylinder head is attached to the engine block by numerous bolts. It has several functions. The cylinder head seals the cylinders on the side opposite to the pistons; it contains short ducts (the ports) for intake and exhaust and the associated intake valves that open to let the cylinder be filled with fresh air and exhaust valves that open to allow the combustion gases to escape. The cylinder head also holds the spark plug in the case of spark ignition engines and the injector for engines that use direct injection. All CI use direct injection. SI engines can use a carburetor, port injection or direct injection. Most SI engines have a single spark plug per cylinder but some have 2. A head gasket prevents the gas from leaking between the cylinder head and the engine block. The opening and closing of the valves is controlled by one or several camshafts and springs –or in some engines– a desmodromic mechanism that uses no springs. The camshaft may press directly the stem of the valve or may act upon a rocker arm, again, either directly or through a pushrod.

The crankcase is sealed at the bottom with a sump that collects the falling oil during normal operation to be cycled again. The cavity created between the cylinder block and the sump houses a crankshaft that converts the reciprocating motion of the pistons to rotational motion. The crankshaft is held in place relative to the engine block by main bearings, which allow it to rotate. Bulkheads in the crankcase form a half of every main bearing; the other half is a detachable cap. In some cases a single main bearing deck is used rather than several smaller caps. A connecting rod is connected to offset sections of the crankshaft (the crankpins) in one end and to the piston in the other end through a gudgeon pin and thus transfers the force and translates the reciprocating motion of the pistons to the circular motion of the crankshaft. The end of the connecting rod attached to the gudgeon pin is called its small end, and the other end, where it's connected to the crankshaft, the big end. The big end has a detachable half to allow assembly around the crankshaft. It's kept together to the connecting rod by removable bolts.

The cylinder head has attached an intake manifold an an exhaust manifold to the corresponding ports. The intake manifold connects to the air filter directly, or to a carburetor when one is present, which is then connected to the air filter. It distributes the air incoming from these devices to the individual cylinders. The exhaust manifold is the first component in the exhaust system. It collects the exhaust gases from the cylinders and drives it to the following component in the path. The exhaust system of an ICE may also include a catalytic converter and muffler. The final section in the path of the exhaust gases is the tailpipe.

Operation

1. Induction

2. Compression

3. Power

4. Exhaust

As their name implies, four-stroke internal combustion engines have four basic steps that repeat with every two revolutions of the engine:

(1) Intake/suction stroke (2) Compression stroke (3) Power/expansion stroke and (4) Exhaust stroke

1. Intake stroke: The first stroke of the internal combustion engine is also known as the suction stroke because the piston moves to the maximum volume position (downward direction in the cylinder) creating a drop in pressure. The inlet valve opens as a result of the cam lobe pressing down on the valve stem, and the vaporized fuel mixture is sucked into the combustion chamber. The inlet valve closes at the end of this stroke.

2. Compression stroke: In this stroke, both valves are closed and the piston starts its movement to the minimum volume position (upward direction in the cylinder) and compresses the fuel mixture. During the compression process, pressure, temperature and the density of the fuel mixture increases.

3. Power stroke: When the piston reaches a point just before top dead center, the spark plug ignites the fuel mixture. The point at which the fuel ignites varies by engine; typically it is about 10 degrees before top dead center. This expansion of gases caused by ignition of the fuel produces the power that is transmitted to the crank shaft mechanism.

4. Exhaust stroke: In the end of the power stroke, the exhaust valve opens. During this stroke, the piston starts its movement in the maximum volume position. The open exhaust valve allows the exhaust gases to escape the cylinder. At the end of this stroke, the exhaust valve closes, the inlet valve opens, and the sequence repeats in the next cycle. Four-stroke engines require two revolutions.

Many engines overlap these steps in time; turbine engines do all steps simultaneously at different parts of the engines.

Ignition

Internal combustion engines require ignition of the mixture, either by spark ignition (SI) or compression ignition (CI). Before the invention of reliable electrical methods, hot tube and flame methods were used. Experimental engines with laser ignition have been built.[3]

Gasoline Ignition Process

Gasoline engine ignition systems generally rely on a combination of alternator or generator and lead–acid battery for electrical power. The battery supplies electrical power for cranking, and supplies electrical power when the engine is off. The battery also supplies electrical power during rare run conditions where the alternator cannot maintain more than 13.8 volts (for a common 12V automotive electrical system). As alternator voltage falls below 13.8 volts, the lead-acid storage battery increasingly picks up electrical load. During virtually all running conditions, including normal idle conditions, the alternator supplies primary electrical power.

Some systems disable alternator field (rotor) power during wide open throttle conditions. Disabling the field reduces alternator pulley mechanical loading to nearly zero, maximizing crankshaft power. In this case the battery supplies all primary electrical power.

Gasoline engines take in a mixture of air and gasoline and compress it to not more than 12.8 bar (1.28 MPa). When mixture is compressed, as the piston approaches the cylinder head and maximum stroke, a spark plug ignites the mixture.

The necessary high voltage, typically 10,000 volts to over 30,000 volts, is supplied by an induction coil or transformer. The induction coil is a fly-back system, using interruption of electrical primary system current through some type of synchronized interrupter. The interrupter can be either contact points or a power transistor. Some ignition systems are capacitive discharge types. CD ignitions use step-up transformers. The step-up transformer uses energy stored in a capacitance to generate electric spark. With either system, a mechanical or electrical control system provides a carefully timed high-voltage to the proper cylinder. This spark, via the spark plug, ignites the air-fuel mixture in the engine's cylinders.

While gasoline internal combustion engines are much easier to start in cold weather than diesel engines, they can still have cold weather starting problems under extreme conditions. For years the solution was to park the car in heated areas. In some parts of the world the oil was actually drained and heated over night and returned to the engine for cold starts. In the early 1950s the gasoline Gasifier unit was developed, where, on cold weather starts, raw gasoline was diverted to the unit where part of the fuel was burned causing the other part to become a hot vapor sent directly to the intake valve manifold. This unit was quite popular until electric engine block heaters became standard on gasoline engines sold in cold climates.[4]

Diesel Ignition Process

Diesel engines and HCCI (Homogeneous charge compression ignition) engines, rely solely on heat and pressure created by the engine in its compression process for ignition. The compression level that occurs is usually twice or more than a gasoline engine. Diesel engines take in air only, and shortly before peak compression, spray a small quantity of diesel fuel into the cylinder via a fuel injector that allows the fuel to instantly ignite. HCCI type engines take in both air and fuel, but continue to rely on an unaided auto-combustion process, due to higher pressures and heat. This is also why diesel and HCCI engines are more susceptible to cold-starting issues, although they run just as well in cold weather once started. Light duty diesel engines with indirect injection in automobiles and light trucks employ glowplugs that pre-heat the combustion chamber just before starting to reduce no-start conditions in cold weather. Most diesels also have a battery and charging system; nevertheless, this system is secondary and is added by manufacturers as a luxury for the ease of starting, turning fuel on and off (which can also be done via a switch or mechanical apparatus), and for running auxiliary electrical components and accessories. Most new engines rely on electrical and electronic engine control units (ECU) that also adjust the combustion process to increase efficiency and reduce emissions.

Two-stroke configuration

Engines based on the two-stroke cycle use two strokes (one up, one down) for every power stroke. Since there are no dedicated intake or exhaust strokes, alternative methods must be used to scavenge the cylinders. The most common method in spark-ignition two-strokes is to use the downward motion of the piston to pressurize fresh charge in the crankcase, which is then blown through the cylinder through ports in the cylinder walls.

Spark-ignition two-strokes are small and light for their power output and mechanically very simple; however, they are also generally less efficient and more polluting than their four-stroke counterparts. In terms of power per cm³, a two-stroke engine produces comparable power to an equivalent four-stroke engine. The advantage of having one power stroke for every 360° of crankshaft rotation (compared to 720° in a 4-stroke motor) is balanced by the less complete intake and exhaust and the shorter effective compression and power strokes. It may be possible for a two-stroke to produce more power than an equivalent four-stroke, over a narrow range of engine speeds, at the expense of less power at other speeds.

Small displacement, crankcase-scavenged two-stroke engines have been less fuel-efficient than other types of engines when the fuel is mixed with the air prior to scavenging allowing some of it to escape out of the exhaust port. Modern designs (Sarich and Paggio) use air-assisted fuel injection, which avoids this loss and provides more efficiency than comparably sized four-stroke engines. Fuel injection is essential for a modern two-stroke engine for it to meet stringent emission standards. The problem of total loss oil consumption, however, remains a cause of high hydrocarbon emissions. The low-pressure direct gasoline injection developed by R Sarich was tested by Ford in an automobile size 2-stroke engine, and in 2012, Orbital won a contract by the Australia government for a two-stroke, direct injection engine for airborne drones.

Research continues into improving many aspects of two-stroke motors including direct fuel injection, amongst other things. The initial results have produced motors that are much cleaner burning than their traditional counterparts. Two-stroke engines are widely used in snowmobiles, lawnmowers, string trimmers, chain saws, jet skis, mopeds, outboard motors, and many motorcycles. Two-stroke engines have the advantage of an increased specific power ratio (i.e. power to volume ratio), typically around 1.5 times that of a typical four-stroke engine.

The largest internal combustion engines in the world are two-stroke diesels, used in some locomotives and large ships. They use forced induction (similar to super-charging, or turbocharging) to scavenge the cylinders; an example of this type of motor is the Wärtsilä-Sulzer turbocharged two-stroke diesel as used in large container ships. It is the most efficient and powerful internal combustion engine in the world with over 50% thermal efficiency.[5][6][7][8] For comparison, the most efficient small four-stroke motors are around 43% thermal efficiency (SAE 900648); size is an advantage for efficiency due to the increase in the ratio of volume to surface area.

Common cylinder configurations include the straight or inline configuration, the more compact V configuration, and the wider but smoother flat or boxer configuration. Aircraft engines can also adopt a radial configuration, which allows more effective cooling. More unusual configurations such as the H, U, X, and W have also been used.

Multiple crankshaft configurations do not necessarily need a cylinder head at all because they can instead have a piston at each end of the cylinder called an opposed piston design. Because fuel inlets and outlets are positioned at opposed ends of the cylinder, one can achieve uniflow scavenging, which, as in the four-stroke engine is efficient over a wide range of engine speeds. Thermal efficiency is improved because of a lack of cylinder heads. This design was used in the Junkers Jumo 205 diesel aircraft engine, using two crankshafts at either end of a single bank of cylinders, and most remarkably in the Napier Deltic diesel engines. These used three crankshafts to serve three banks of double-ended cylinders arranged in an equilateral triangle with the crankshafts at the corners. It was also used in single-bank locomotive engines, and is still used for marine propulsion engines and marine auxiliary generators.

See external links for a in-cylinder combustion video in a two-stroke, optically accessible motorcycle engine.

Two-stroke cycle

This system manages to pack one power stroke into every two strokes of the piston (up-down). This is achieved by exhausting and recharging the cylinder simultaneously.

The steps involved here are:

- Intake and exhaust occur at bottom dead center. Some form of pressure is needed, either crankcase compression or super-charging.

- Compression stroke: Fuel-air mix is compressed and ignited. In case of diesel: Air is compressed, fuel is injected and self-ignited.

- Power stroke: Piston is pushed downward by the hot exhaust gases.

Two Stroke Spark Ignition (SI) engine:

In a two-stroke SI engine a cycle is completed in two strokes of a piston or one complete revolution (360°) of a crankshaft. In this engine the intake and exhaust strokes are eliminated and ports are used instead of valves. In this cycle, the gasoline is mixed with lubricant oil, resulting in a simpler, but more environmentally damaging system, as the excess oils do not burn and are left as a residue. As the piston proceeds downward another port is opened, the fuel/air intake port. Air/fuel/oil mixtures come from the carburetor, where it was mixed, to rest in an adjacent fuel chamber. When the piston moves further down and the cylinder doesn't have anymore gases, fuel mixture starts to flow to the combustion chamber and the second process of fuel compression starts. The design carefully considers the point that the fuel-air mixture should not mix with the exhaust, therefore the processes of fuel injection and exhausting are synchronized to avoid that concern. It should be noted that the piston has three functions in its operation:

- The piston acts as the combustion chamber with the cylinder and compresses the air/fuel mixture, receives back the liberated energy, and transfers it to the crankshaft.

- The piston motion creates a vacuum that sucks the fuel/air mixture from the carburetor and pushes it from the crankcase (adjacent chamber) to the combustion chamber.

- The sides of the piston act like the valves, covering and uncovering the intake and exhaust ports drilled into the side of the cylinder wall.

The major components of a two-stroke spark ignition engine are the:

- Cylinder: A cylindrical vessel in which a piston makes an up and down motion.

- Piston: A cylindrical component making an up and down movement in the cylinder

- Combustion chamber: A portion above the cylinder in which the combustion of the fuel-air mixture takes place

- Intake and exhaust ports : Ports that carry fresh fuel-air mixture into the combustion chamber and products of combustion away

- Crankshaft: A shaft that converts reciprocating motion of the piston into rotary motion

- Connecting rod: A rod that connects the piston to the crankshaft

- Spark plug: An ignition-source in the cylinder head that initiates the combustion process

- Reed valve: Fuel/air check valve

Operation: When the piston moves from bottom dead center (BDC) to top dead center (TDC) the fresh air and fuel mixture enters the crank chamber through the intake port. The mixture enters due to the pressure difference between the crank chamber and the outer atmosphere while simultaneously the fuel-air mixture above the piston is compressed.

Ignition: With the help of a spark plug, ignition takes place at the top of the stroke. Due to the expansion of the gases the piston moves downwards covering the intake port and compressing the fuel-air mixture inside the crank chamber. When the piston is at bottom dead center, the burnt gases escape from the exhaust port.

At the time the transfer port is uncovered the compressed charge from the crank chamber enters into the combustion chamber through the transfer port. The fresh charge is deflected upwards by a hump provided on the top of the piston and removes the exhaust gases from the combustion chamber. Again the piston moves from bottom dead center to top dead center and the fuel-air mixture is compressed when the both the exhaust port and transfer ports are covered. The cycle is repeated.

Advantages: • It has no camshaft and valve mechanism, hence simplifying its operation and construction • For one complete revolution of the crankshaft, the engine executes one cycle—the 4-stroke executes one cycle per two crankshafts revolutions • Less weight and easier to manufacture • High power-to-weight ratio

Disadvantages: • The lack of lubrication system that protects the engine parts from wear. Accordingly, the 2-stroke engines have a shorter life. • 2-stroke engines are less fuel efficient and produce more pollution than 4-stroke engines • Sometimes part of the fuel leaks to the exhaust with the exhaust gases In conclusion, based on the above advantages and disadvantages, two-stroke engines are supposed to operate in vehicles where the weight of the engine must be small, and it is not used continuously for long periods.

Four-stroke

Engines based on the four-stroke ("Otto cycle") have one power stroke for every four strokes (up-down-up-down) and employ spark plug ignition. Combustion occurs rapidly, and during combustion the volume varies little ("constant volume").[9] They are used in cars, larger boats, some motorcycles, and many light aircraft. They are generally quieter, more efficient, and larger than their two-stroke counterparts.

The steps involved here are:

- Intake stroke: Air and vaporized fuel are drawn in.

- Compression stroke: Fuel vapor and air are compressed and ignited.

- Combustion stroke: Fuel combusts and piston is pushed downwards.

- Exhaust stroke: Exhaust is driven out. During the 1st, 2nd, and 4th stroke the piston is relying on power and the momentum generated by the other pistons. In that case, a four-cylinder engine would be less powerful than a six- or eight-cylinder engine.

There are a number of variations of these cycles, most notably the Atkinson and Miller cycles. The diesel cycle is somewhat different.

Split-cycle engines separate the four strokes of intake, compression, combustion and exhaust into two separate but paired cylinders. The first cylinder is used for intake and compression. The compressed air is then transferred through a crossover passage from the compression cylinder into the second cylinder, where combustion and exhaust occur. A split-cycle engine is really an air compressor on one side with a combustion chamber on the other.

Previous split-cycle engines have had two major problems - poor breathing (volumetric efficiency) and low thermal efficiency. However, new designs are being introduced that seek to address these problems.

The Scuderi Engine addresses the breathing problem by reducing the clearance between the piston and the cylinder head through various turbo charging techniques. The Scuderi design requires the use of outwardly opening valves that enable the piston to move very close to the cylinder head without the interference of the valves. Scuderi addresses the low thermal efficiency via firing ATDC.

Firing ATDC can be accomplished by using high-pressure air in the transfer passage to create sonic flow and high turbulence in the power cylinder.

Diesel cycle

Most truck and automotive diesel engines use a cycle reminiscent of a four-stroke cycle, but with a compression heating ignition system, rather than needing a separate ignition system. This variation is called the diesel cycle. In the diesel cycle, diesel fuel is injected directly into the cylinder so that combustion occurs at constant pressure, as the piston moves.

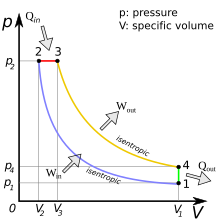

Otto cycle: Otto cycle is the typical cycle for most of the cars internal combustion engines, that work using gasoline as a fuel. Otto cycle is exactly the same one that was described for the four-stroke engine. It consists of the same four major steps: Intake, compression, ignition and exhaust.

PV diagram for Otto cycle On the PV-diagram, 1-2: Intake: suction stroke 2-3: Isentropic Compression stroke 3-4: Heat addition stroke 4-5: Exhaust stroke (Isentropic expansion) 5-2: Heat rejection The distance between points 1-2 is the stroke of the engine. By dividing V2/V1, we get: r, where r is called the compression ratio of the engine.

Five-stroke engine

In 1879, Nikolaus Otto manufactured and sold double expansion engine (the double and triple expansion principles had ample usage in steam engines), with two small cylinders at both sides of a low-pressure larger cylinder, where a second expansion of exhaust stroke gas took place; the owner returned it, alleging poor performance. In 1906, the concept was incorporated in a car built by EHV (Eisenhuth Horseless Vehicle Company), and in the 21st century, Ilmor designed and successfully tested a 5-stroke double expansion internal combustion engine, with high power output and low SFC.[clarification needed]

Six-stroke engine

The six-stroke engine was invented in 1883. Four kinds of six-stroke use a regular piston in a regular cylinder (Griffin six-stroke, Bajulaz six-stroke, Velozeta six-stroke and Crower six stroke), firing every three crankshaft revolutions. The systems capture the wasted heat of the four-stroke Otto cycle with an injection of air or water.

The Beare Head and "piston charger" engines operate as opposed-piston engines, two pistons in a single cylinder, firing every two revolutions rather more like a regular four-stroke.

Obsolete

The very first internal combustion engines did not compress the mixture. The first part of the piston downstroke drew in a fuel-air mixture, then the inlet valve closed and, in the remainder of the down-stroke, the fuel-air mixture fired. The exhaust valve opened for the piston upstroke. These attempts at imitating the principle of a steam engine were very inefficient.

Combustion turbines

Gas turbines

A gas turbine is called a gas turbine because it compresses a gas, usually air. There are three stages to a turbine: 1) air is drawn through a compressor where the temperature rises due to compression, 2) fuel is added in the combuster, and 3) hot air is exhausted through turbines blades which rotate a shaft connected to the compressor.

A gas turbine is a rotary machine similar in principle to a steam turbine and it consists of three main components: a compressor, a combustion chamber, and a turbine. The air, after being compressed in the compressor, is heated by burning fuel in it. About ⅔ of the heated air, combined with the products of combustion, expands in a turbine, producing work output that drives the compressor. The rest (about ⅓) is available as useful work output.

Jet engine

The jet engine takes a large volume of hot gas from a combustion process (typically a gas turbine, but rocket forms of jet propulsion often use solid or liquid propellants, and ramjet forms also lack the gas turbine) and feeds it through a nozzle that accelerates the jet to high speed. As the jet accelerates through the nozzle, this creates thrust and in turn does useful work.

Brayton cycle

A gas turbine is a rotary machine somewhat similar in principle to a steam turbine and it consists of three main components: a compressor, a combustion chamber, and a turbine. The air is compressed by the compressor where a temperature rise occurs, further heated by combustion of injected fuel which heats and expands the air, this energy is tapped by the turbine and exhausted, which powers the compressor and provides thrust.

Gas turbine cycle engines employ a continuous combustion system where compression, combustion, and expansion occur simultaneously at different places in the engine—giving continuous power. Notably, the combustion takes place at constant pressure, rather than with the Otto cycle, constant volume.

Wankel engines

The Wankel engine (rotary engine) does not have piston strokes. It operates with the same separation of phases as the four-stroke engine with the phases taking place in separate locations in the engine. In thermodynamic terms it follows the Otto engine cycle, so may be thought of as a "four-phase" engine. While it is true that three power strokes typically occur per rotor revolution due to the 3:1 revolution ratio of the rotor to the eccentric shaft, only one power stroke per shaft revolution actually occurs; this engine provides three power 'strokes' per revolution per rotor giving it a greater power-to-weight ratio than piston engines. This type of engine was most notably used in the Mazda RX-8, the earlier RX-7, and other models.

Fuels and oxidizers

All internal combustion engines depend on combustion of a chemical fuel, typically with oxygen from the air (though it is possible to inject nitrous oxide to do more of the same thing and gain a power boost). The combustion process typically results in the production of a great quantity of heat, as well as the production of steam and carbon dioxide and other chemicals at very high temperature; the temperature reached is determined by the chemical make up of the fuel and oxidisers (see stoichiometry), as well as by the compression and other factors.

Fuels

The most common modern fuels are made up of hydrocarbons and are derived mostly from fossil fuels (petroleum). Fossil fuels include diesel fuel, gasoline and petroleum gas, and the rarer use of propane. Except for the fuel delivery components, most internal combustion engines that are designed for gasoline use can run on natural gas or liquefied petroleum gases without major modifications. Large diesels can run with air mixed with gases and a pilot diesel fuel ignition injection. Liquid and gaseous biofuels, such as ethanol and biodiesel (a form of diesel fuel that is produced from crops that yield triglycerides such as soybean oil), can also be used. Engines with appropriate modifications can also run on hydrogen gas, wood gas, or charcoal gas, as well as from so-called producer gas made from other convenient biomass. Experiments have also been conducted using powdered solid fuels, such as the magnesium injection cycle.

Presently, fuels used include:

- Petroleum:

- Petroleum spirit (North American term: gasoline, British term: petrol)

- Petroleum diesel.

- Autogas (liquified petroleum gas).

- Compressed natural gas.

- Jet fuel (aviation fuel)

- Residual fuel

- Coal:

- Gasoline can be made from carbon (coal) using the Fischer-Tropsch process

- Diesel fuel can be made from carbon using the Fischer-Tropsch process

- Biofuels and vegoils:

- Peanut oil and other vegoils.

- Biofuels:

- Biobutanol (replaces gasoline).

- Biodiesel (replaces petrodiesel).

- Dimethyl Ether (replaces petrodiesel).

- Bioethanol and Biomethanol (wood alcohol) and other biofuels (see Flexible-fuel vehicle).

- Biogas

- Hydrogen (mainly spacecraft rocket engines)

Even fluidized metal powders and explosives have seen some use. Engines that use gases for fuel are called gas engines and those that use liquid hydrocarbons are called oil engines; however, gasoline engines are also often colloquially referred to as, "gas engines" ("petrol engines" outside North America).

The main limitations on fuels are that it must be easily transportable through the fuel system to the combustion chamber, and that the fuel releases sufficient energy in the form of heat upon combustion to make practical use of the engine.

Diesel engines are generally heavier, noisier, and more powerful at lower speeds than gasoline engines. They are also more fuel-efficient in most circumstances and are used in heavy road vehicles, some automobiles (increasingly so for their increased fuel efficiency over gasoline engines), ships, railway locomotives, and light aircraft. Gasoline engines are used in most other road vehicles including most cars, motorcycles, and mopeds. Note that in Europe, sophisticated diesel-engined cars have taken over about 45% of the market since the 1990s. There are also engines that run on hydrogen, methanol, ethanol, liquefied petroleum gas (LPG), biodiesel, paraffin and tractor vaporizing oil (TVO).

Hydrogen

Hydrogen could eventually replace conventional fossil fuels in traditional internal combustion engines. Alternatively fuel cell technology may come to deliver its promise and the use of the internal combustion engines could even be phased out.

Although there are multiple ways of producing free hydrogen, those methods require converting combustible molecules into hydrogen or consuming electric energy. Unless that electricity is produced from a renewable source—and is not required for other purposes— hydrogen does not solve any energy crisis. In many situations the disadvantage of hydrogen, relative to carbon fuels, is its storage. Liquid hydrogen has extremely low density (14 times lower than water) and requires extensive insulation—whilst gaseous hydrogen requires heavy tankage. Even when liquefied, hydrogen has a higher specific energy but the volumetric energetic storage is still roughly five times lower than gasoline. However, the energy density of hydrogen is considerably higher than that of electric batteries, making it a serious contender as an energy carrier to replace fossil fuels. The 'Hydrogen on Demand' process (see direct borohydride fuel cell) creates hydrogen as needed, but has other issues, such as the high price of the sodium borohydride that is the raw material.

Oxidizers

Since air is plentiful at the surface of the earth, the oxidizer is typically atmospheric oxygen, which has the advantage of not being stored within the vehicle. This increases the power-to-weight and power-to-volume ratios. Other materials are used for special purposes, often to increase power output or to allow operation under water or in space.

- Compressed air has been commonly used in torpedoes.

- Compressed oxygen, as well as some compressed air, was used in the Japanese Type 93 torpedo. Some submarines carry pure oxygen. Rockets very often use liquid oxygen.

- Nitromethane is added to some racing and model fuels to increase power and control combustion.

- Nitrous oxide has been used—with extra gasoline—in tactical aircraft, and in specially equipped cars to allow short bursts of added power from engines that otherwise run on gasoline and air. It is also used in the Burt Rutan rocket spacecraft.

- Hydrogen peroxide power was under development for German World War II submarines. It may have been used in some non-nuclear submarines, and was used on some rocket engines (notably the Black Arrow and the Me-163 rocket plane).

- Other chemicals such as chlorine or fluorine have been used experimentally, but have not been found practical.

Cooling

Cooling is required to remove excessive heat — over heating can cause engine failure, usually from wear, cracking or warping. Two most common forms of engine cooling are air-cooled and water cooled. Most modern automotive engines and larger engines are water cooled, while most power tool engines and other small engines are air cooled. Some engines (air or water cooled) also have an oil cooler. In some engines, especially for turbine engine blade cooling and liquid rocket engine cooling, fuel is used as a coolant, simultaneously preheating the fuel, before injecting it into a combustion chamber.

Starting

An internal combustion engine is not usually self-starting so an auxiliary machine is required to start it. Many different systems have been used in the past but modern engines are usually started by an electric motor in the small and medium sizes or by compressed air in the large sizes.

Measures of engine performance

Engine types vary greatly in a number of different ways:

- energy efficiency

- fuel/propellant consumption (brake specific fuel consumption for shaft engines, thrust specific fuel consumption for jet engines)

- power-to-weight ratio

- thrust to weight ratio

- Torque curves (for shaft engines) thrust lapse (jet engines)

- Compression ratio for piston engines, overall pressure ratio for jet engines and gas turbines

Energy efficiency

Once ignited and burnt, the combustion products—hot gases—have more available thermal energy than the original compressed fuel-air mixture (which had higher chemical energy). The available energy is manifested as high temperature and pressure that can be translated into work by the engine. In a reciprocating engine, the high-pressure gases inside the cylinders drive the engine's pistons.

Once the available energy has been removed, the remaining hot gases are vented (often by opening a valve or exposing the exhaust outlet) and this allows the piston to return to its previous position (top dead center, or TDC). The piston can then proceed to the next phase of its cycle, which varies between engines. Any heat that is not translated into work is normally considered a waste product and is removed from the engine either by an air or liquid cooling system.

Internal combustion engines are primarily heat engines, and as such their theoretical efficiency can be calculated by idealized thermodynamic cycles. The efficiency of a theoretical cycle cannot exceed that of the Carnot cycle, whose efficiency is determined by the difference between the lower and upper operating temperatures of the engine. The upper operating temperature of a terrestrial engine is limited by the thermal stability of the materials used to construct it. All metals and alloys eventually melt or decompose, and there is significant researching into ceramic materials that can be made with greater thermal stability and desirable structural properties. Higher thermal stability allows for greater temperature difference between the lower and upper operating temperatures, hence greater thermodynamic efficiency.

The thermodynamic limits assume that the engine is operating under ideal conditions: a frictionless world, ideal gases, perfect insulators, and operation for infinite time. Real world applications introduce complexities that reduce efficiency. For example, a real engine runs best at a specific load, termed its power band. The engine in a car cruising on a highway is usually operating significantly below its ideal load, because it is designed for the higher loads required for rapid acceleration.[citation needed] In addition, factors such as wind resistance reduce overall system efficiency. Engine fuel economy is measured in miles per gallon or in liters per 100 kilometres. The volume of hydrocarbon assumes a standard energy content.

Most steel engines have a thermodynamic limit of 37%. Even when aided with turbochargers and stock efficiency aids, most engines retain an average efficiency of about 18%-20%.[10] Rocket engine efficiencies are much better, up to 70%, because they operate at very high temperatures and pressures and can have very high expansion ratios.[11] Electric motors are better still, at around 85-90% efficiency or more, but they rely on an external power source (often another heat engine at a power plant subject to similar thermodynamic efficiency limits).

There are many inventions aimed at increasing the efficiency of IC engines. In general, practical engines are always compromised by trade-offs between different properties such as efficiency, weight, power, heat, response, exhaust emissions, or noise. Sometimes economy also plays a role in not only the cost of manufacturing the engine itself, but also manufacturing and distributing the fuel. Increasing the engine's efficiency brings better fuel economy but only if the fuel cost per energy content is the same.

Measures of fuel efficiency and propellant efficiency

For stationary and shaft engines including propeller engines, fuel consumption is measured by calculating the brake specific fuel consumption, which measures the mass flow rate of fuel consumption divided by the power produced.

For internal combustion engines in the form of jet engines, the power output varies drastically with airspeed and a less variable measure is used: thrust specific fuel consumption (TSFC), which is the mass of propellant needed to generate impulses that is measured in either pound force-hour or the grams of propellant needed to generate an impulse that measures one kilonewton-second.

For rockets, TSFC can be used, but typically other equivalent measures are traditionally used, such as specific impulse and effective exhaust velocity.

Air and noise pollution

Air pollution

Internal combustion engines such as reciprocating internal combustion engines produce air pollution emissions, due to incomplete combustion of carbonaceous fuel. The main derivatives of the process are carbon dioxide CO

2, water and some soot — also called particulate matter (PM). The effects of inhaling particulate matter have been studied in humans and animals and include asthma, lung cancer, cardiovascular issues, and premature death. There are, however, some additional products of the combustion process that include nitrogen oxides and sulfur and some uncombusted hydrocarbons, depending on the operating conditions and the fuel-air ratio.

Not all of the fuel is completely consumed by the combustion process; a small amount of fuel is present after combustion, and some of it reacts to form oxygenates, such as formaldehyde or acetaldehyde, or hydrocarbons not originally present in the input fuel mixture. Incomplete combustion usually results from insufficient oxygen to achieve the perfect stoichiometric ratio. The flame is "quenched" by the relatively cool cylinder walls, leaving behind unreacted fuel that is expelled with the exhaust. When running at lower speeds, quenching is commonly observed in diesel (compression ignition) engines that run on natural gas. Quenching reduces efficiency and increases knocking, sometimes causing the engine to stall. Incomplete combustion also leads to the production of carbon monoxide (CO). Further chemicals released are benzene and 1,3-butadiene that are also hazardous air pollutants.

Increasing the amount of air in the engine reduces emissions of incomplete combustion products, but also promotes reaction between oxygen and nitrogen in the air to produce nitrogen oxides (NOx). NOx is hazardous to both plant and animal health, and leads to the production of ozone (O3). Ozone is not emitted directly; rather, it is a secondary air pollutant, produced in the atmosphere by the reaction of NO"x" and volatile organic compounds in the presence of sunlight. Ground-level ozone is harmful to human health and the environment. Though the same chemical substance, ground-level ozone should not be confused with stratospheric ozone, or the ozone layer, which protects the earth from harmful ultraviolet rays.

Carbon fuels contain sulfur and impurities that eventually produce sulfur monoxides (SO) and sulfur dioxide (SO2) in the exhaust, which promotes acid rain.

In the United States, nitrogen oxides, PM, carbon monoxide, sulphur dioxide, and ozone, are regulated as criteria air pollutants under the Clean Air Act to levels where human health and welfare are protected. Other pollutants, such as benzene and 1,3-butadiene, are regulated as hazardous air pollutants whose emissions must be lowered as much as possible depending on technological and practical considerations.

Non-road engines

The emission standards used by many countries have special requirements for non-road engines which are used by equipment and vehicles that are not operated on the public roadways. The standards are separated from the road vehicles.[12]

Noise pollution

Significant contributions to noise pollution are made by internal combustion engines. Automobile and truck traffic operating on highways and street systems produce noise, as do aircraft flights due to jet noise, particularly supersonic-capable aircraft. Rocket engines create the most intense noise.

Idling

Internal combustion engines continue to consume fuel and emit pollutants when idling so it is desirable to keep periods of idling to a minimum. Many bus companies now instruct drivers to switch off the engine when the bus is waiting at a terminal.

In the UK (but only in England), the Road Traffic Vehicle Emissions Fixed Penalty Regulations 2002 (Statutory Instrument 2002 No. 1808) [13] introduced the concept of a "stationary idling offence". This means that a driver can be ordered "by an authorised person ... upon production of evidence of his authorisation, require him to stop the running of the engine of that vehicle" and a "person who fails to comply ... shall be guilty of an offence and be liable on summary conviction to a fine not exceeding level 3 on the standard scale". Only a few local authorities have implemented the regulations, one of them being Oxford City Council.[14]

See also

References

- ^ a b "History of Technology: Internal Combustion engines". Encyclopædia Britannica. Britannica.com. Retrieved 2012-03-20.

- ^ a b Pulkrabek, Willard W. (1997). Engineering Fundamentals of the Internal Combustion Engine. Prentice Hall. p. 2. ISBN 9780135708545.

- ^ "Laser sparks revolution in internal combustion engines". Physorg.com. 2011-04-20. Retrieved 2013-12-26.

- ^ "Gasifier Aids Motor Starting Under Arctic Conditions". Popular Mechanics: 149. January 1953.

- ^ Low Speed Engines, MAN Diesel.[dead link]

- ^ "CFX aids design of world's most efficient steam turbine" (PDF). Retrieved 2010-08-28.

- ^ "New Benchmarks for Steam Turbine Efficiency - Power Engineering". Pepei.pennnet.com. 2010-08-24. Retrieved 2010-08-28.

- ^ Takaishi, Tatsuo; Numata, Akira; Nakano, Ryouji; Sakaguchi, Katsuhiko (March 2008). "Approach to High Efficiency Diesel and Gas Engines" (PDF). Mitsubishi Heavy Industries Technical Review. 45 (1). Retrieved 2011-02-04.

- ^ "Ideal Otto Cycle". Grc.nasa.gov. 2008-07-11. Retrieved 2010-08-28.

- ^ "Improving IC Engine Efficiency". Courses.washington.edu. Retrieved 2010-08-28.

- ^ Rocket propulsion elements 7th edition-George Sutton, Oscar Biblarz pg 37-38

- ^ "2013 Global Sourcing Guide" (PDF). Diesel & Gas Turbine Publications. Retrieved 2013-12-26.

- ^ "The Road Traffic (Vehicle Emissions) (Fixed Penalty) (England) Regulations 2002". 195.99.1.70. 2010-07-16. Retrieved 2010-08-28.

- ^ "CITY DEVELOPMENT - Fees & Charges 2010-11" (PDF). Oxford City Council. November 2011. Retrieved 2011-02-04.

Bibliography

- Nunney, Malcom J. (2007). Light and Heavy Vehicle Technology. Elsevier. ISBN 978-0-7506-8037-0.

- Anyebe, E.A (2009). Combustion Engine and Operations, Automobile Technology Handbook, Vol. 2.

- Dr. R. K. Singal: 'Internal Combustion Engines', Kataria Books, New Delhi, India. ISBN 978-93-5014-214-1

- Patents ES0156621; ES433850; ES0230551; ES0249247

Further reading

- Singer, Charles Joseph; Raper, Richard, A History of Technology: The Internal Combustion Engine, edited by Charles Singer ... [et al.], Clarendon Press, 1954-1978. pp. 157–176

- Setright, LJK. "Some unusual engines", 1975 The Institution of Mechanical Engineers, London. ISBN 0 85298 208 9

- Suzuki, Takashi, PhD. "The Romance of Engines", 1997 SAE, ISBN 1-56091-911-6

- Horst O. Hardenberg, The Middle Ages of the Internal Combustion Engine, 1999, Society of Automotive Engineers (SAE).

- Gunston, Bill. "Development of Piston Aero Engines", 1999 PSL, ISBN 978 1 85260 619 0

External links

- Combustion video - in-cylinder combustion in an optically accessible, 2-stroke engine

- Animated Engines - explains a variety of types

- Intro to Car Engines - Cut-away images and a good overview of the internal combustion engine

- Walter E. Lay Auto Lab - Research at The University of Michigan

- youtube - Animation of the components and built-up of a 4-cylinder engine

- youtube - Animation of the internal moving parts of a 4-cylinder engine

- Next generation engine technologies retrieved May 9, 2009

- MIT Overview - Present & Future Internal Combustion Engines: Performance, Efficiency, Emissions, and Fuels

- Engine Combustion Network - Open forum for international collaboration among experimental and computational researchers in engine combustion.

- Automakers Show Interest in ffan Unusual Engine Design

- How Car Engines Work

- A file on unusual engines [1]

- Aircraft Engine Historical Society -AEHS [2]